Hot Selling Products

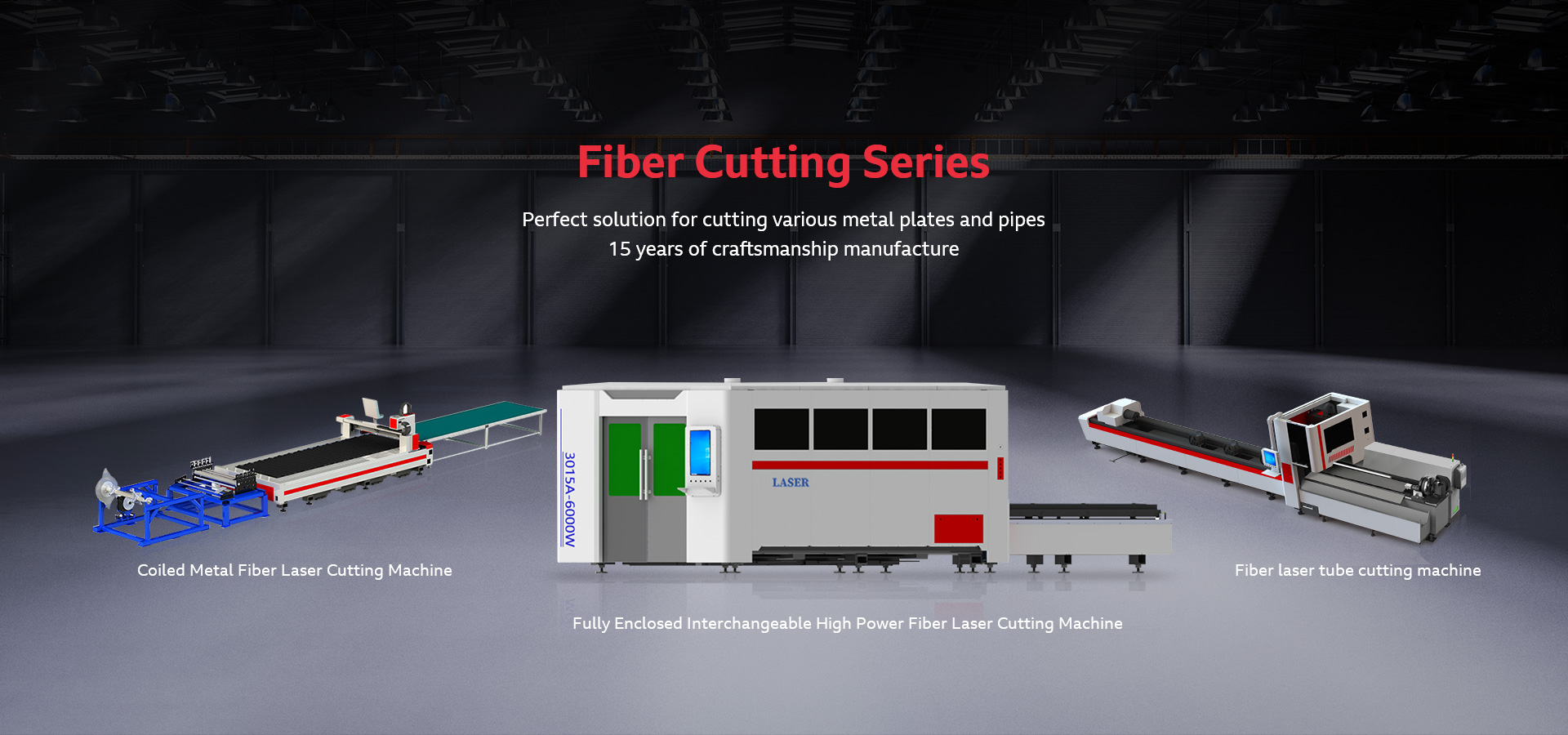

- Fiber Laser Cutting Machine

- Fiber Laser Welding Machine

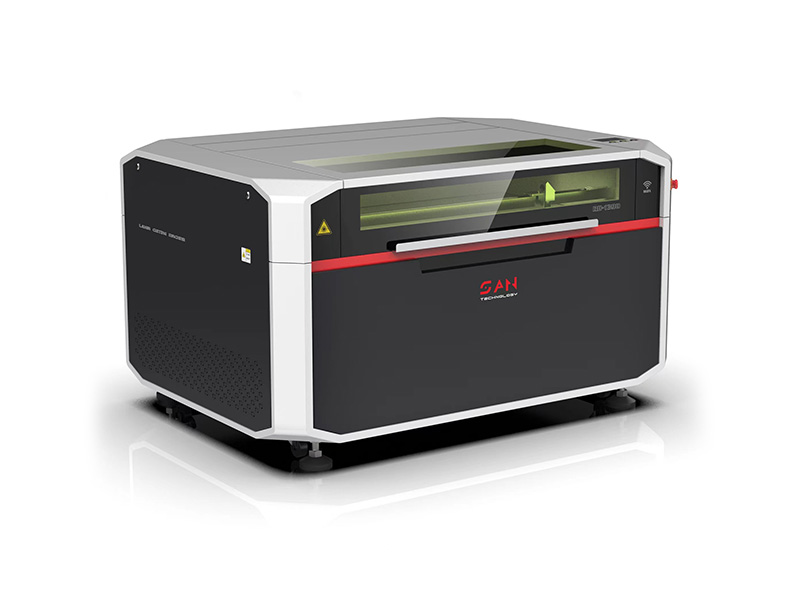

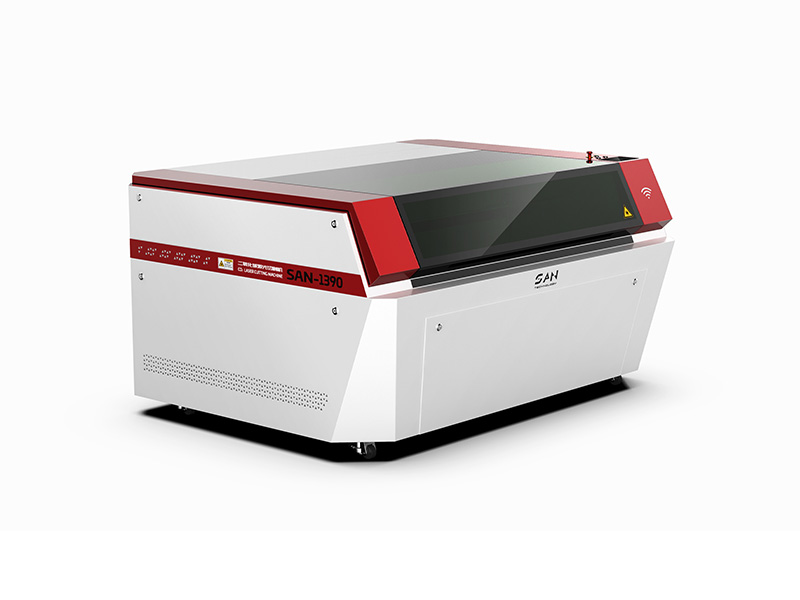

- CO2 Laser Cutting Machine

- Laser Marking Machine

core advantages

-

CUTTING SOLUTIONS

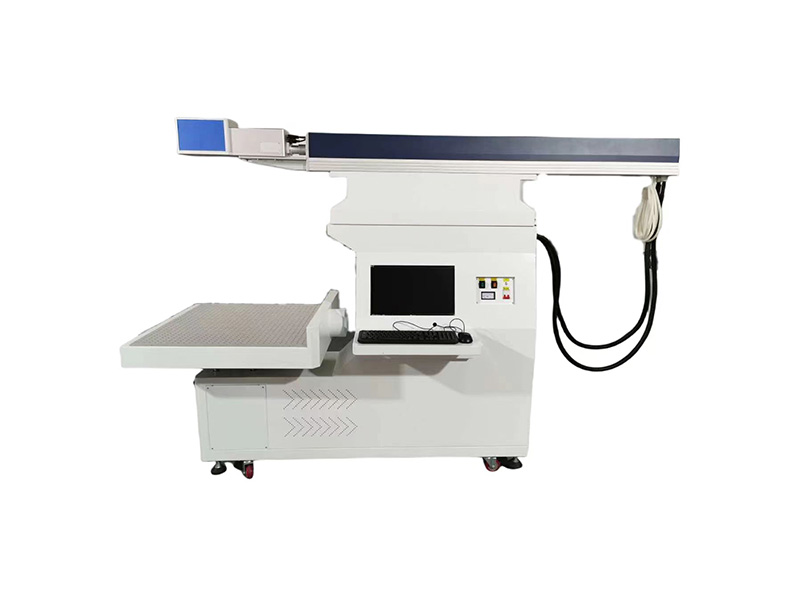

CUTTING SOLUTIONSFiber Laser Cutting Machine Engineering Solutions

Learn more -

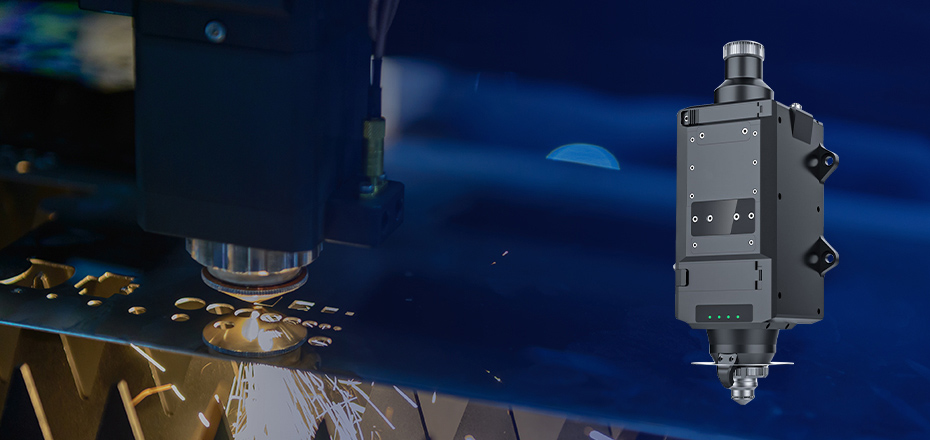

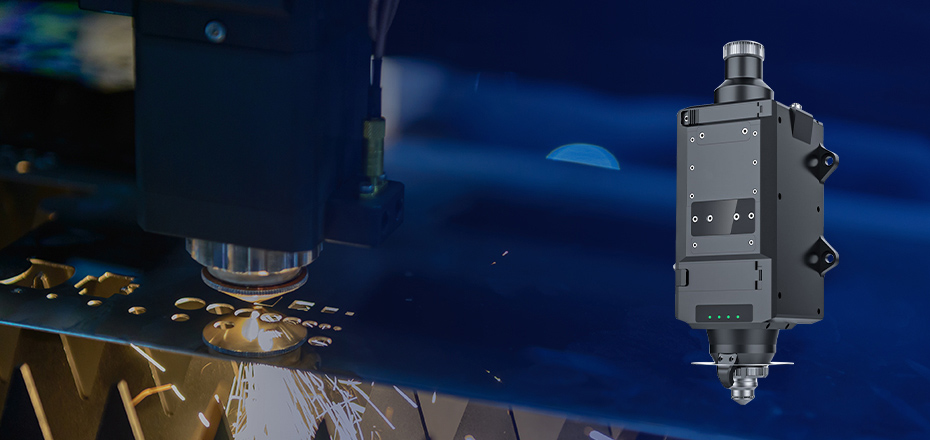

Cutting Technology

Cutting TechnologyIntelligent induction cutting head, cutting anti-collision technology

Learn more

news center

-

Jan 10,

2025Laser welding machine: ordinary wire feeding VS double wire feeding!Laser welding technology has become a cornerstone of modern manufacturing, offering unparalleled precision, speed, and versatility. A key aspect of its operation lies in the wire feeding mechanism, which introduces filler material into the welding process to join or repair components effectively. Among the available options, ordinary wire feeding and double wire feeding stand out as two distinct methods, each catering to specific industrial needs. Understanding their differences is important for manufacturers looking to optimize their welding performance, achieve desired joint properties, and meet the demands of diverse applications.

Understanding Ordinary Wire Feeding Laser Welding Machine

Ordinary wire feeding is the most common configuration for laser welding machines. In this method, a single wire is fed into the welding zone to serve as filler material. The wire melts under the focused laser beam and fills gaps or joins materials, creating a high-quality weld.

Key Features: Conventional wire-feed laser welding machines utilize a single wire as filler material, fed consistently into the welding zone. The system integrates a precise wire feeder with the laser beam, ensuring accurate material delivery and minimal wastage. These machines are ideal for joining metals with fine tolerances, where additional material is necessary to fill gaps or strengthen the weld. They typically support a range of wire diameters and materials, such as steel, aluminum, and alloys, allowing for versatility across applications. Their straightforward design prioritizes simplicity, precision, and reliability, making them suitable for various industries.

Advantages: The primary advantage of conventional wire-feed laser welding machines is their simplicity and cost-effectiveness. Their ability to provide precise material delivery results in high-quality welds with minimal defects. They are relatively easy to operate and maintain, with lower operational costs due to single-wire usage. This makes them a practical choice for routine welding tasks where high deposition rates or advanced features are not essential.

Limitations: Despite their reliability, conventional wire-feed laser welding machines face limitations in more demanding applications. Their single-wire design limits deposition rates, reducing efficiency for welding thick or large-scale components. They lack the flexibility to weld dissimilar materials or achieve tailored metallurgical properties in joints. Additionally, their suitability for advanced processes, such as additive manufacturing or high-speed welding, is limited, making them less versatile compared to dual-wire or more advanced configurations.

Understanding Double Wire Feeding Laser Welding Machine

Double wire feeding is an advanced configuration in laser welding that introduces two wires simultaneously into the weld zone. This system is designed to address the limitations of ordinary wire feeding by increasing deposition rates, improving joint properties, and expanding the range of welding applications.

Key Features: Dual-wire laser welding machines utilize two wires simultaneously, fed into the welding zone at controlled speeds. The wires can be of the same or different materials, offering versatility in joint customization and metallurgical properties. These machines are equipped with advanced feeding systems to ensure precise control over wire delivery, enabling higher deposition rates. The ability to independently adjust the feed rates of each wire allows for tailored welding strategies, making them ideal for complex tasks such as dissimilar material joining, thick workpiece welding, and additive manufacturing.

Advantages: The primary advantage of dual-wire laser welding machines is their significantly enhanced deposition rate, which increases welding efficiency and reduces processing time. They offer flexibility in material selection, allowing for the welding of dissimilar metals or the addition of alloying elements to improve joint strength, corrosion resistance, or other properties. Additionally, their ability to handle thicker materials and produce high-quality welds with fewer defects enhances their appeal for demanding industrial tasks.

Limitations: While offering advanced capabilities, dual-wire laser welding machines come with higher complexity and cost. The additional wire feeder system and control mechanisms increase the initial investment and require more maintenance. Operating these machines often demands skilled personnel to manage the intricate feeding process and optimize parameters. Moreover, the higher material consumption associated with dual-wire feeding can lead to increased operational costs, making them less economical for small-scale or routine welding tasks. Their advanced features may also be underutilized in applications where single-wire feeding suffices, reducing their cost-effectiveness in such scenarios.

Ordinary wire feeding and double wire feeding each offer distinct advantages for laser welding machines. Ordinary wire feeding is ideal for general-purpose tasks, while double wire feeding excels in high-performance, demanding applications. By understanding the differences, applications, and limitations of these methods, you can make an informed decision that maximizes efficiency, quality, and cost-effectiveness in your welding operations.

Related product links

-

Jan 09,

2025The portable handheld laser marking machine!The portable handheld laser marking machine delivers a fast and efficient solution for marking large, heavy, or immobile objects that are challenging to mark using traditional methods. Perfect for engraving metals, plastics, rubber, ceramics, and glass, this portable device ensures permanent, high-contrast, and detailed markings across a range of materials.

The flexibility of the handheld laser marking system is reflected in its ability to work in fixed offices and be used in various production line. It also has an advanced control system that can accurately mark serial numbers, logos, barcodes and complex patterns. With a marking speed of up to 7000mm/s, it significantly boosts production efficiency by reducing processing times.

Handheld Laser Marking Machine Applications

l Electronic Components: Resistors, capacitors, chips, printed circuit boards, computer keyboards, charger adapter, etc.

l Instruments and Meters: Panels, nameplates, panel labels, precision equipment, etc.

l Hardware Tools: Cutting tools, tools, measuring instruments, etc.

l Mechanical Parts: Pistons, bearings, gears, etc.

l Daily Necessities: Cosmetics, door signs, medals, crafts, keychains, sanitary fixtures, glasses, LED lights, etc.

l Jewelry: Rings, necklaces, earrings, gold jewelry, silver jewelry, etc.

l Medical: Medical devices, surgical instruments, medical packaging, etc.

l Packaging: Tableware, food, beverages, tobacco and alcohol, plastic packaging bags, etc.

Related product links

-

Jan 09,

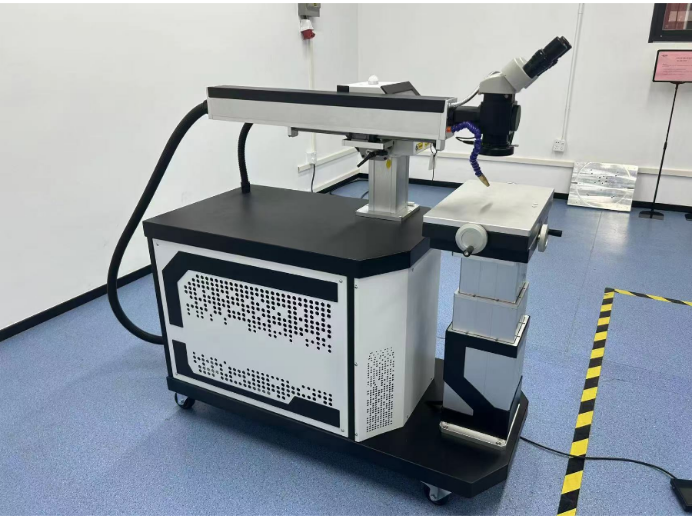

2025Principles and characteristics of laser welding machine mold repair!The working principle of the laser welding machine is to use laser deposition welding, which uses laser high heat energy and concentrated fixed-point welding technology to effectively handle all small parts of welding and repair work, making up for the shortcomings of traditional argon welding and cold welding technology in repairing fine surfaces.

The laser welding machine can weld various metal steels, such as S136, 718, SKD61, SKD11, 2344, NAK80, 8407, P20, stainless steel, beryllium copper, aluminum alloy, titanium alloy, etc. After welding, there are no sand holes, pores, collapse, deformation, high bonding strength, firm, and not easy to fall off.

In addition to the adjustable laser energy, spot diameter, pulse width and working frequency, the laser welding machine repairs the mold and also adjusts the single pulse waveform specifically for welding different materials (the pulse waveform is slightly different when welding different materials such as steel, beryllium copper, aluminum, etc., and the pulse waveform also affects the hardness after welding).

The laser head can be easily separated from the main unit. In addition to welding and repairing precision molds such as mobile phones and digital cameras, it can also repair large molds such as automobiles and motorcycles.

The laser welding machine has the following advantages for repairing molds:

● The diameter of the laser welding point is only 0.2mm~2.0mm

● The heating range is small, and there will be no defects such as deformation, pores, sand holes, collapse, etc.

● The impulse of the laser makes the welding effect firm, the adhesion is strong, and it is not easy to fall off

● Processable materials such as mold steel, stainless steel, beryllium copper and precious metals

● Can repair cracks, broken corners, mold edges, and worn sealing edges

● Can be ground into a smooth surface after welding

● Can be welded on extremely hard materials (~HRC 60)

Related product links

-

Jan 08,

2025Advantages of mold laser welding machine in mold repair application!The advantages of mold laser welding machine in mold repair are that if a mold is damaged or has gaps, it cannot produce products accurately. The mold repair speed is faster and the cost should be cheaper. The laser mold welding machine is also called deposition welding. The working principle of the system is to use laser high thermal energy and concentrated fixed-point welding technology to effectively handle all small parts of welding and repair work, making up for the shortcomings of traditional argon arc welding technology in repairing and welding fine surfaces. It avoids the two thresholds of thermal strain and post-processing, greatly saving the production cycle of the mold.

What products are suitable for mold laser welding machine: It is specially designed for the mold industry and is used for repairing precision molds, such as digital products, mobile phones, toys, automobiles, motorcycles and other mold manufacturing and molding industries. Through the repair of the mold, the original mold can be fully utilized again, which greatly saves production costs and improves work efficiency. This technology can also be used to modify the design or size of the mold and shorten the product development cycle.

What are the advantages of mold laser welding machine:

Tailor-made for the mold industry, introducing German technology, adopting a unique structural design, suitable for repairing various large, medium and small molds.

1. It adopts imported ceramic focusing cavity, which is corrosion-resistant and high-temperature resistant. The cavity life is (8-10) years, and the xenon lamp life is more than 8 million times.

2. It adopts the world's most advanced automatic shading system to eliminate the stimulation of light to the eyes during work.

3. The laser head can rotate 360 degrees, the overall optical path part can rotate 360 degrees, and it can be electrically lifted up and down, and pushed forward and backward, which is particularly suitable for repairing various large, medium and small molds.

4. Parameter adjustment is controlled by intelligent remote control, which is simple and fast to operate.

5. The workbench can be electrically raised and lowered and moved in three dimensions.

6. The light spot size can be electrically adjusted.

Related product links

-

Jan 08,

2025Reasons why mold laser welding machine is not strong!Now many customers complain that the mold laser welding machine is not strong. What is the reason for the mold laser welding machine to be weak? Today, SAN LASER laser welding machine manufacturer will give you a brief introduction.

In addition to being an expert in repairing molds, the mold laser welding machine is also an expert in welding, whether it is stainless steel metal accessories welding or gold and silver jewelry welding. But there are times when the welding is not strong, and then we have to analyze the reasons.

There are many reasons why the workpiece welded by the mold laser welding machine is not firm. The following two are the most common ones:

1. The workpiece is rusted or oily. If this is the case, you need to remove the rust and oil first.

2. The workpiece surface has been electroplated and has other metal (such as zinc) films on the surface. At this time, the corresponding laser waveform should be adjusted according to different electroplating processes.

3. The laser power of the laser welding machine is too small and the energy is insufficient. At this time, you need to consider a machine with higher power.

Related product links

-

about san laser

about san laserA pioneer in the world of Laser technology for the last 10 years, proudly presents its latest laser machines for various applications.

Learn more -

Application and Clent Stories

Application and Clent StoriesThe wide applications of these machines work on materials like Leather, Wood, Acrylic, Fabric and Paper processing industries.

Learn more