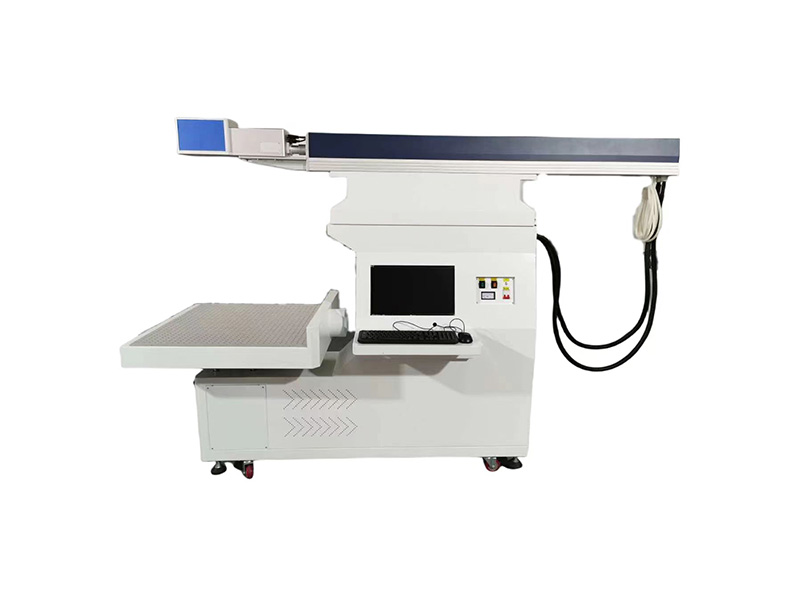

Fiber laser marking machine

Get a free quoteFiber Laser Marking Machine can process all metal and some non-metal materials. It can be used on stainless steel, carbon steel, copper plate, aluminum plate and many more. It a best choice for industry needs. The machine has longest service life among all other marking technology.

It can process a variety of metal and non-metal materials. In particular, marking high-hardness, high-melting-point, and brittle materials is more advantageous.

It belongs to non-contact processing, no damage to products, no tool wear, and good marking quality.

The laser beam is thin, the processing matenial consumption is very small, and the processing heat affected area is small.

High processing efficiency, computer control and easy automation

General configuration

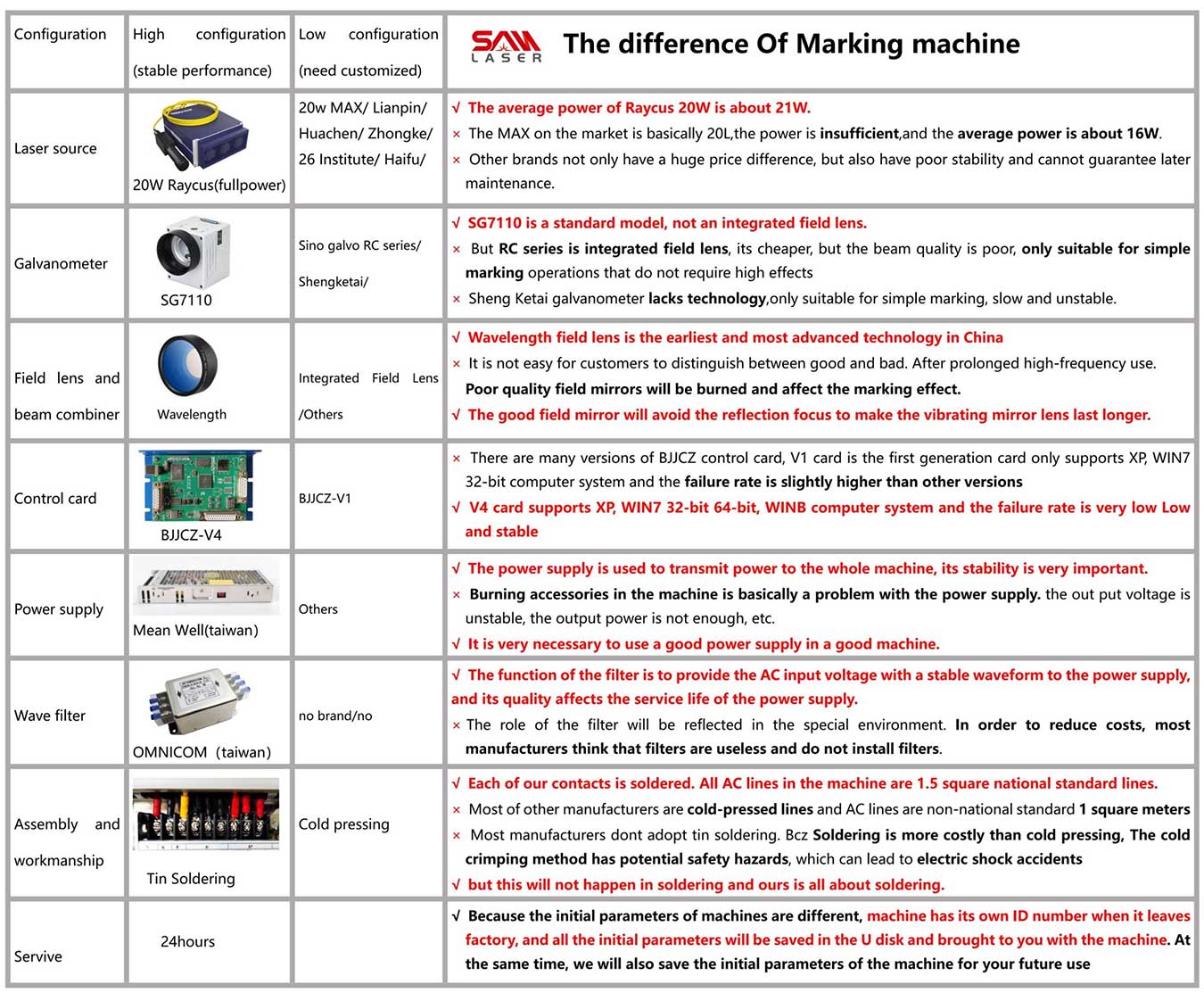

1. Raycus/Max laser source.

2. Beijing JCZ EZCAD Card; support WIN7 WIN8 32bit 64bit all systems;

3. 110/150mm galvo lens , brand : Nanjing Wavelength--Best brand in Market

4. Location by Double red light testing and changing holder will be easier;

5. SINO GALVO high speed galvometer;

6. Desktop with 55cm z pillar height ;with z axis electric up and down ;

7. Using Air cooling, so volume of the machine is small. The quality of laser beam is good ; Fastest & Best service we will provide for laser source .

Optional accessories

Quality control

Video

Technical Parameter

| Beam quality | M2:1.5 |

| Average output power | 20 w/30 w/50 w/70w/100 w |

| Maximum linear marking speed | 8000 mm/s |

| Laser wavelength | 1064 nm |

| Marking range | 70-300-mm(optional) |

| Laser repetition frequency | 20 KHZ-80 KHZ,1-500 KHZ |

| Minimum character height | The 0.2 mm |

| Marking depth | >0.01mm |

| Repeat accuracy | The 0.005 mm |

| Minimum line width | The 0.01 mm |

| Electridty demand | 220 v/50 hz |

| Power consumption of the whole machine | <500 w |

| Cooling system | Air cooling |

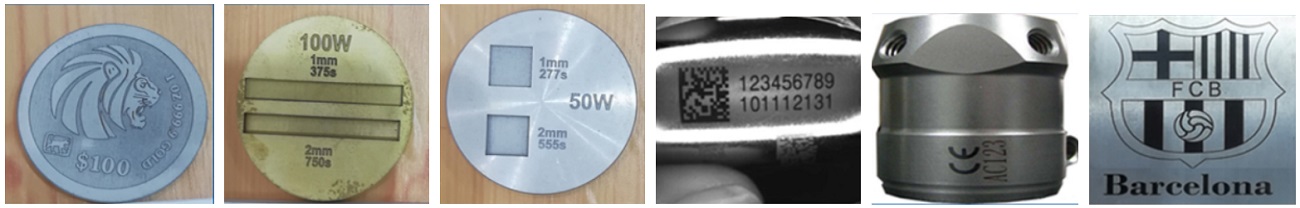

Application

Especially suitable for application in some fine engraving, high precision products, It is applied on precision equipment, auto parts , hardware , tools, accessories , electronic components , food packaging , integrated circuits (IC), electrical appliances, mobile communications , jewelry,etc.

Production Facility

Fiber laser marking machine

Fiber laser marking machine