Fiber Laser Welding Machine

-

QCW/Fiber Mobile mold repair laser welding machine

-

QCW/Fiber Mould laser welding machine with crane

-

Handheld fiber laser welding machine

-

Fiber transmission laser welding machine

-

Jewelry welding

-

Handheld galvanometer laser welding machine for Battery Weld Repairs

-

Galvanometer laser mold welding machine

-

Mold repair fiber laser welding

-

Intergrated boom laser welding machine

-

Automatic laser welding machine

-

Automatic platform laser welding machine

-

Gantry galvanometer laser welding machine

-

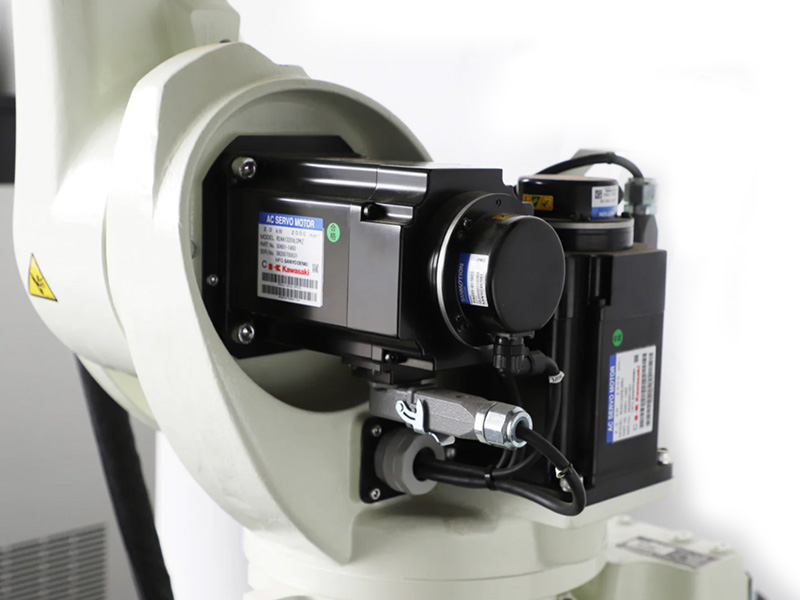

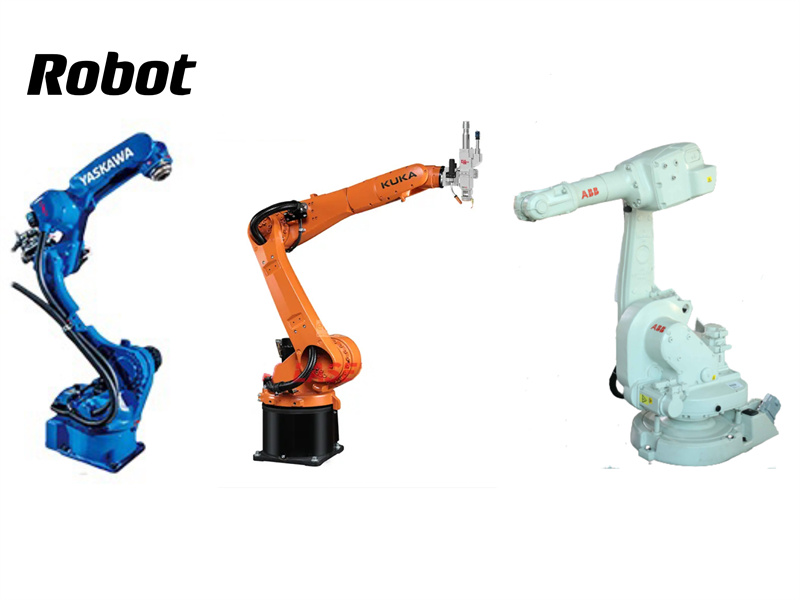

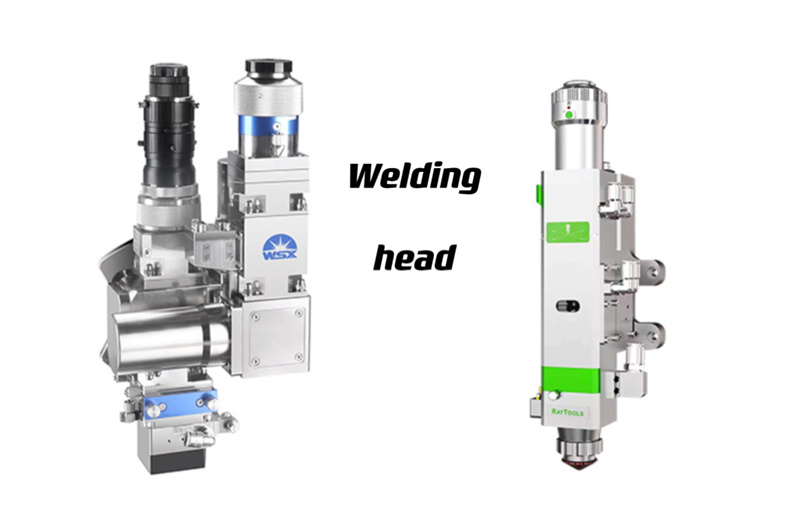

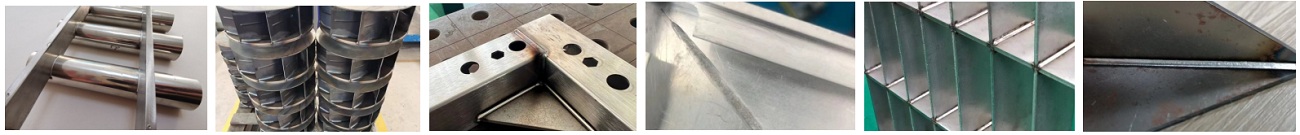

Robot welding machine

-

Handheld fiber laser cleaning machine

-

Pulse laser cleaning machine

Robot welding machine

Robot welding machine