Ground rail laser cutting machine

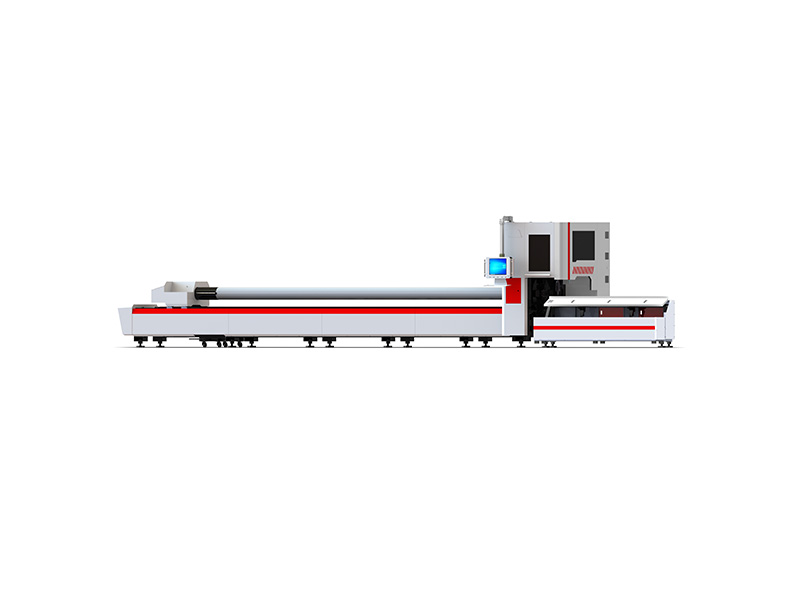

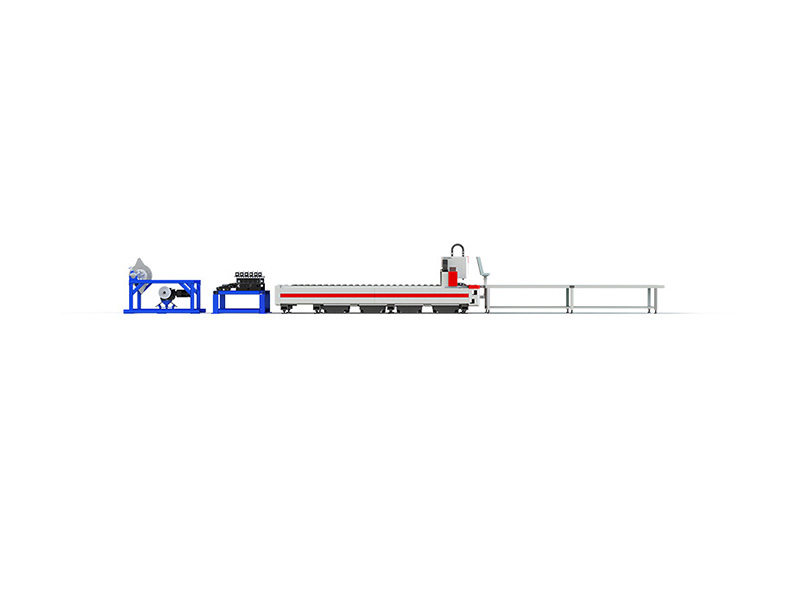

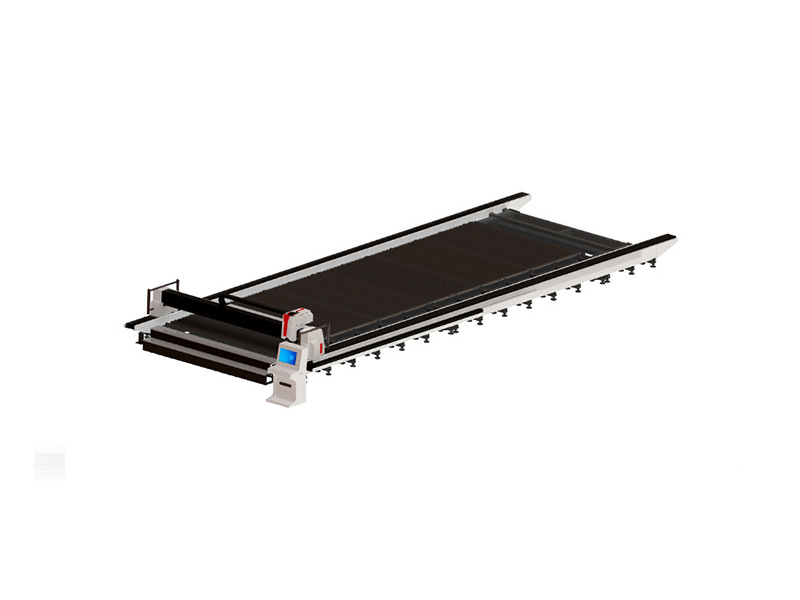

Get a free quoteGround Rail Gantry type Large Format Fiber Metal Laser Cutting Machine represents the latest advancement in metal cutting technology, offering exceptional solutions for high-precision cutting of metal materials. It integrates multiple cutting-edge technologies to provide manufacturing industries with efficient, high-quality, and highly customizable production tools.

Segmented Ground-Track Bed:

The Ground-Track Gantry Laser Cutting Machine features a segmented ground-track bed design that allows easy assembly and disassembly, enabling customizations for ultra-large formats as per requirements. It supports cutting of large-sized and thick materials, significantly enhancing work efficiency.

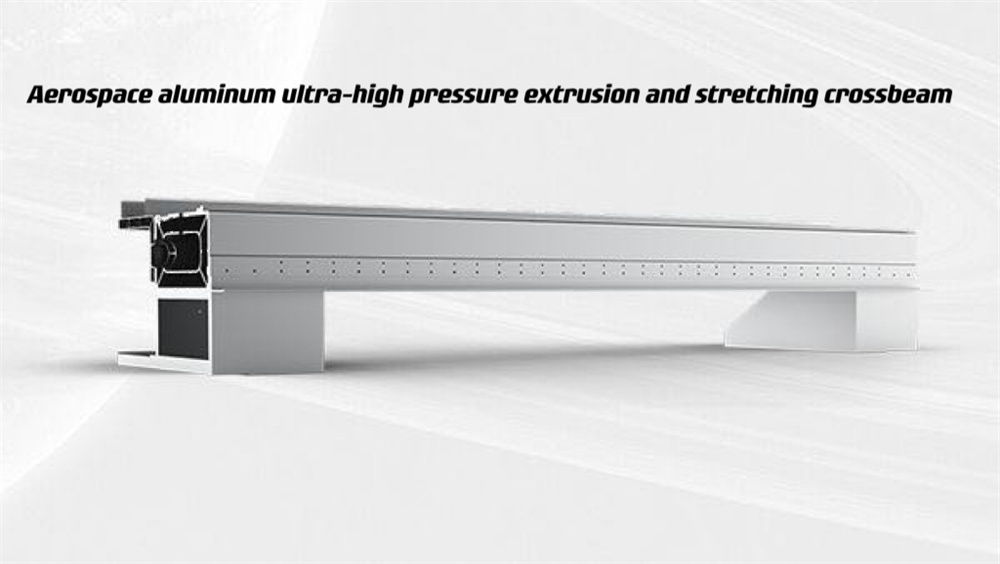

High Stability:

The mobile gantry ground-track structure ensures outstanding stability, while the lightweight cast aluminum beam offers excellent dynamic performance.

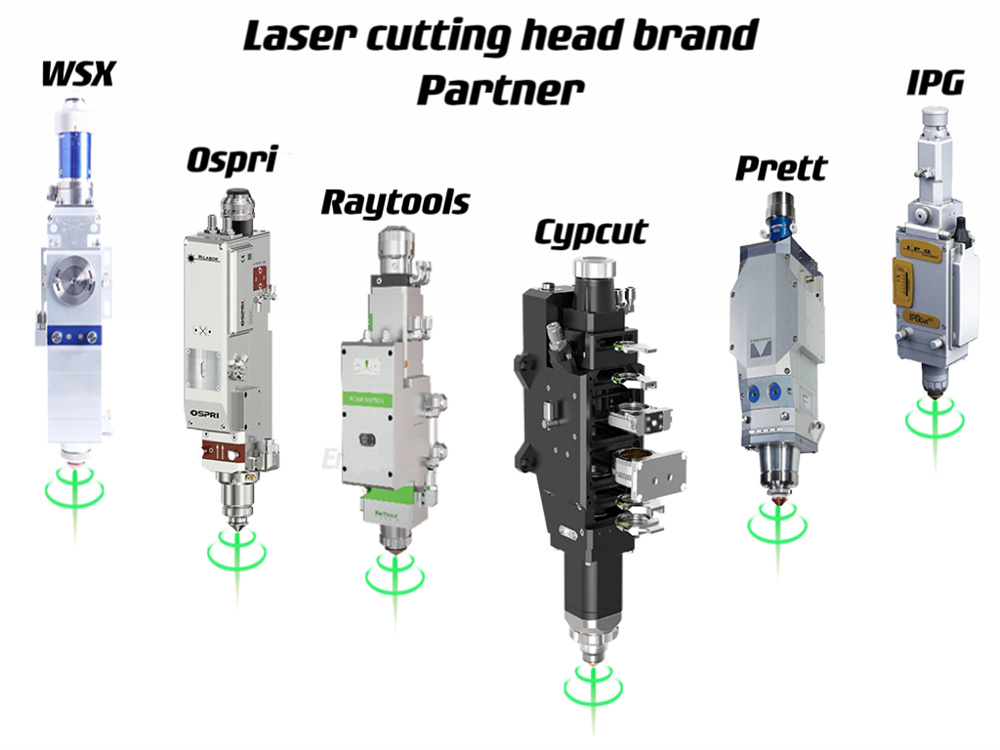

Intelligent Bevel Cutting:

Equipped with an intelligent bevel cutting head, it can achieve ±45° bevel cutting and significantly increase cutting efficiency by producing various bevels in a single pass.

Intelligent Clean Cutting Mode:

The Ground-Track Fiber Laser Cutting Machine is equipped with a dynamic exhaust system that efficiently removes dust and debris, creating a clean working environment.

High-Performance Laser Source:

It utilizes a high-performance fiber laser source from a well-known domestic brand, dedicated to providing high-performance, high-quality, and cost-effective fiber laser sources and integrated solutions. This laser source has been widely used in aerospace, 3D printing, automotive, petroleum, electronics, communications, photovoltaics, and medical industries.

Video

Features & Advantages

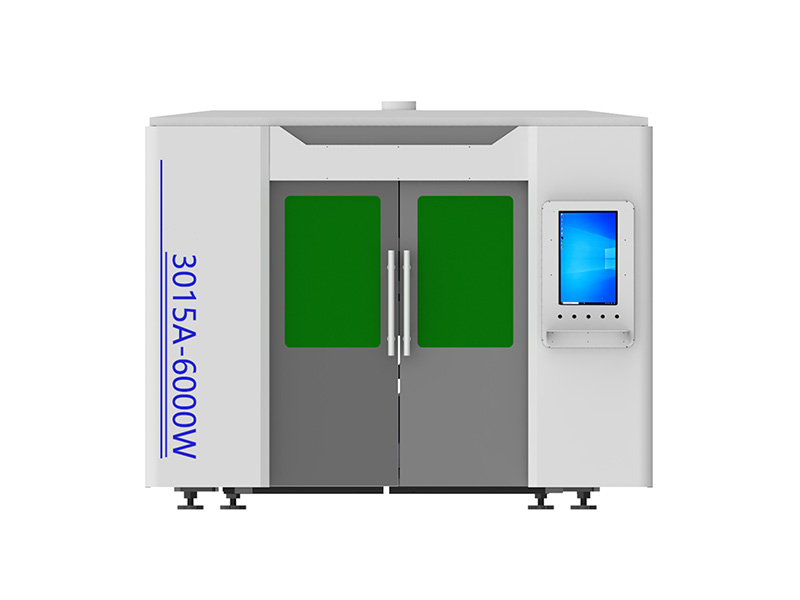

Intelligent CNC Cutting System:

Equipped with a BaiChu CNC system, it achieves automatic edge detection, autofocus, and automatic cutting, improving processing efficiency. It supports wireless remote control, allows for free adjustment of clamping pressure, and features multiple safety protection functions for user-friendly operation.

High-Strength Welded Bed:

The high-strength steel plate welded bed uses a bevel welding process to ensure uniform strength between steel plates. Through high-temperature annealing, internal stress is eliminated, ensuring excellent tensile strength, toughness, hardness, and resistance to deformation, ensuring a robust and durable bed structure with zero deformation.

New-Generation Welded Steel Beam:

Made from high-performance manganese steel, the beam is manufactured using clever structural design, enhancing rigidity during high-speed operations. After heat treatment, it achieves strong rigidity and strength, demonstrating excellent earthquake resistance and stability to ensure the beam remains deformation-free during prolonged use.

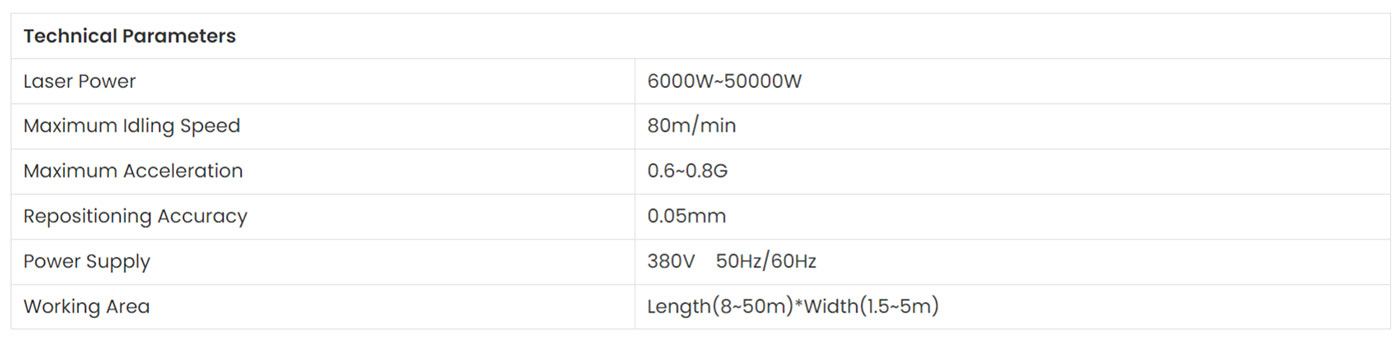

Technical Parameter

Application

Material Applicability: Designed for high-speed cutting of medium-thickness metal sheets, including carbon steel, stainless steel, aluminum, copper, brass, etc. (cutting thickness and speed mainly depend on laser power), it offers an ultra-wide cutting range suitable for large sheet cutting needs.

Application: Widly used in engineering machinery, shipbuilding, gantry cranes, environmental protection equipment, refrigeration equipment, aerospace machinery, and automotive manufacturing, among various other mechanical manufacturing sectors.

Ground rail laser cutter

Ground rail laser cutter