-

Exploring the Main Types of YAG Laser Welding Machines for Jewelry!

Exploring the Main Types of YAG Laser Welding Machines for Jewelry: Ideal Solutions for Goldsmiths Manufacturing WholesaleWith the increasing demand for precision and efficiency in the jewelry industry, YAG laser welding machines have become a key tool for goldsmiths manufac...May 23,2025Learn more -

Galvanometer Laser Mold Welding Machine Introduction!

OverviewThe Galvanometer Laser Mold Welding Machine is a high-precision, automated solution designed for mold repair, precision welding, and surface modification. Utilizing advanced galvanometer scanning technology and fiber laser sources, it ensures exceptional accuracy, speed, ...Apr 24,2025Learn more -

Pulse Laser Cleaning vs. Fiber Laser Cleaning: Differences & Recommendations

In the field of laser cleaning technology, two primary solutions stand out: pulse laser cleaning machines and fiber laser cleaning machines. Both technologies offer effective cleaning for various industrial applications, but their differences make them suitable for dif...Apr 23,2025Learn more -

Market Analysis and Development Trends of Laser Mold Welding Machines (as of 2024-2025)

1. Market Overview Global Market Size: The global laser mold welding machine market was valued at approximately $1.2 billion in 2024, with a projected CAGR of 7.5% (2025-2030), driven by demand from automotive, aerospace, and precision manufacturing sectors.Key Regions:Asia-...Apr 18,2025Learn more -

Why Our Welding Machines Perfectly Adapt to the American Market? Localized Solutions for Efficient Production!

In the global industrial equipment market, adapting to regional requirements is crucial. Our welding machines, with their localized design, strict certifications, and efficient service, have become the ideal choice for customers in the Americas. This article details how we o...Apr 17,2025Learn more -

Subject: Laser Welding Users' #5 Concern!

After-sales service and technical support rank as the TOP5 concern for laser welding machine users.Industry data reveals:• 60%+ buyers prioritize after-sales support when selecting equipment (Laser Manufacturing News 2023)• 35% of customers switch suppliers due to poor servi...Apr 17,2025Learn more -

Common Methods of Mold Repair!

Molds are of vital importance in industrial production. However, issues such as wear and cracks occur frequently. How should one choose the right welding repair technology? As a leading brand in the field of mold welding equipment, San Laser. This article will provide a detailed ...Apr 14,2025Learn more -

How to choose a handheld welding machine?

In recent years, laser welding machines have become increasingly popular with metal product manufacturers. Because like laser cutting, many advantages of laser welding are being recognized and utilized to produce better quality products with higher production efficiency and lower...Apr 12,2025Learn more -

Analysis of Application Trends of Laser Mold Welding Machines in the Lithium Battery Industry!

The application of laser mold welding technology in the lithium battery industry is experiencing rapid growth, driven by advancements in precision manufacturing and the increasing demand for high-performance energy storage solutions. Below is a comprehensive analysis of its devel...Apr 12,2025Learn more -

Laser welding machine applicable industry!

Welding is one of the indispensable processes in modern industrial production. Traditional welding methods such as arc welding and argon arc welding often lead to welding defects if the temperature and time cannot be well controlled. Laser welding machines are easy to operate and...Mar 31,2025Learn more

Fiber Laser Welding Machine

-

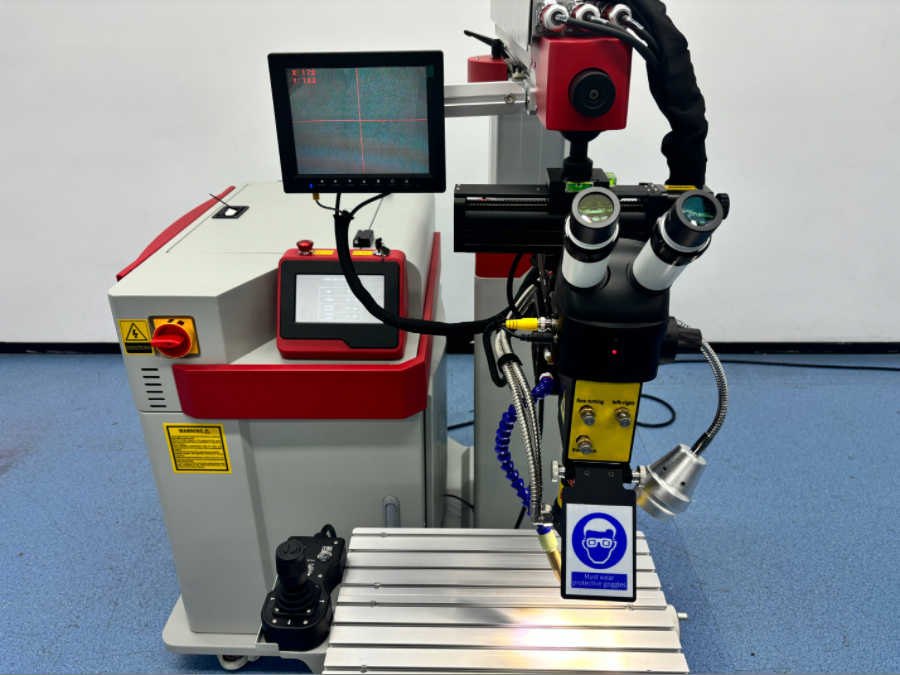

QCW/Fiber Mobile mold repair laser welding machine

-

QCW/Fiber Mould laser welding machine with crane

-

Handheld fiber laser welding machine

-

Fiber transmission laser welding machine

-

Jewelry welding

-

Handheld galvanometer laser welding machine for Battery Weld Repairs

-

Galvanometer laser mold welding machine

-

Mold repair fiber laser welding

-

Intergrated boom laser welding machine

-

Automatic laser welding machine

-

Automatic platform laser welding machine

-

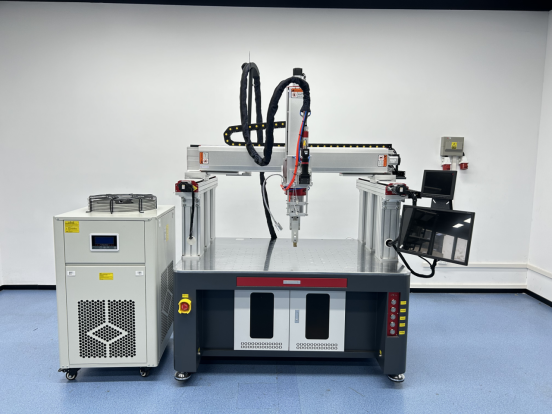

Gantry galvanometer laser welding machine

-

Robot welding machine

-

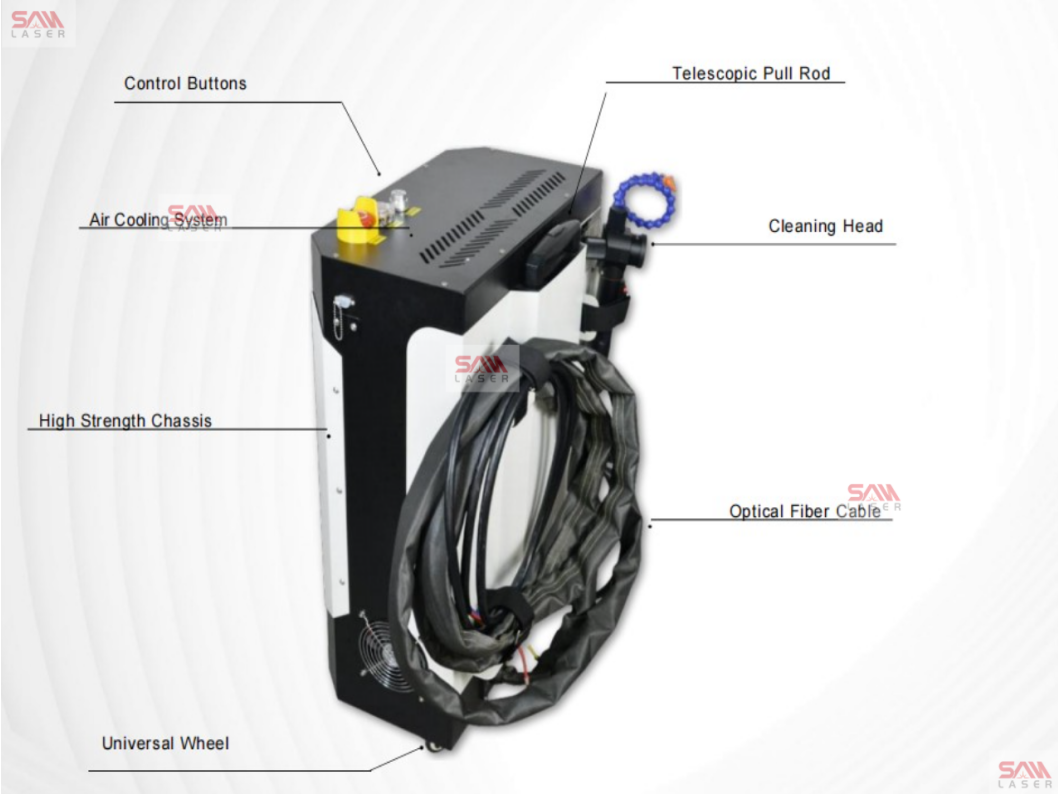

Handheld fiber laser cleaning machine

-

Pulse laser cleaning machine

Welder News

Welder News