- No.609, Centre Of Huijin Nanxiang, Yinxiang Road, Nanxiang Town, Jiading District, Shanghai, China

- sherry@sanmachines.com

- +86-18616767021

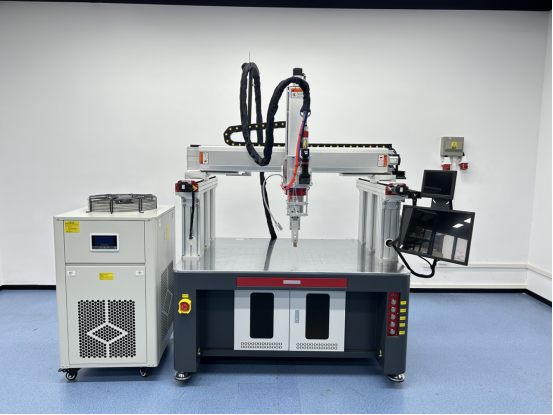

Galvanometer Laser Mold Welding Machine Introduction!

Overview

The Galvanometer Laser Mold Welding Machine is a high-precision, automated solution designed for mold repair, precision welding, and surface modification. Utilizing advanced galvanometer scanning technology and fiber laser sources, it ensures exceptional accuracy, speed, and repeatability, making it ideal for industries requiring micron-level precision.

Pulse Laser Cleaning Machine

Key Features

Galvanometer Scanning System

Ultra-Fast Positioning: Mirrors controlled by high-speed motors direct the laser beam with micron-level accuracy (±0.01mm), enabling complex welding paths and fine details.

Dynamic Focus: Automatically adjusts focal length to maintain consistent energy density on curved or uneven surfaces.

Fiber Laser Source

Wavelength: 1070nm (ideal for metals like steel, aluminum, copper, and alloys).

Power Options: 200W–500W (adjustable for deep penetration or minimal heat input).

Pulse Control: Nanosecond or millisecond pulses for precise energy control.

Technical Advantages:

Precision: Minimum spot size 50μm, positioning accuracy ±5μm

Low Heat Input: HAZ (Heat Affected Zone) <0.1mm

Material Compatibility: Processes tool steels (H13, SKD11), carbides, and copper alloys

Efficiency: Typical repair time 5-30 seconds per defect

Automation: Compatible with CAD/CAM programming and robotic integration

Non-Contact Welding

Eliminates mechanical stress on molds/parts, reducing deformation risks.

User-Friendly Software

Pre-programmed welding patterns (spot, line, custom shapes).

Real-time monitoring and parameter adjustments (power, speed, pulse frequency).

Technical Specifications

Parameter Specification Laser Type Fiber Laser (IPG/RAYCUS)Power Range200W–500WWelding Depth0.1mm–2mm (adjustable)Spot Size0.02mm–0.2mmPositioning Accuracy±0.01mmCooling System Air/Water Cooling (stable operation)Software Windows-based, CAD/CAM compatible

Applications

Mold Repair: Fix cracks, wear, or defects in injection/forging/die-casting molds.

Precision Welding: Micro-welding for electronics, medical devices, and automotive parts.

Surface Cladding: Enhance hardness/corrosion resistance with alloy coatings.

Advantages vs. Traditional Methods

Speed: 3–5x faster than TIG welding.

Precision: 0.01mm accuracy vs. 0.1mm+ with manual methods.

Quality: Minimal porosity, no post-processing required.

Cost-Efficiency: Reduces material waste and labor costs.

Get professional support now

Related product links

Welder News

Welder News