QCW/Fiber Mould laser welding machine with crane

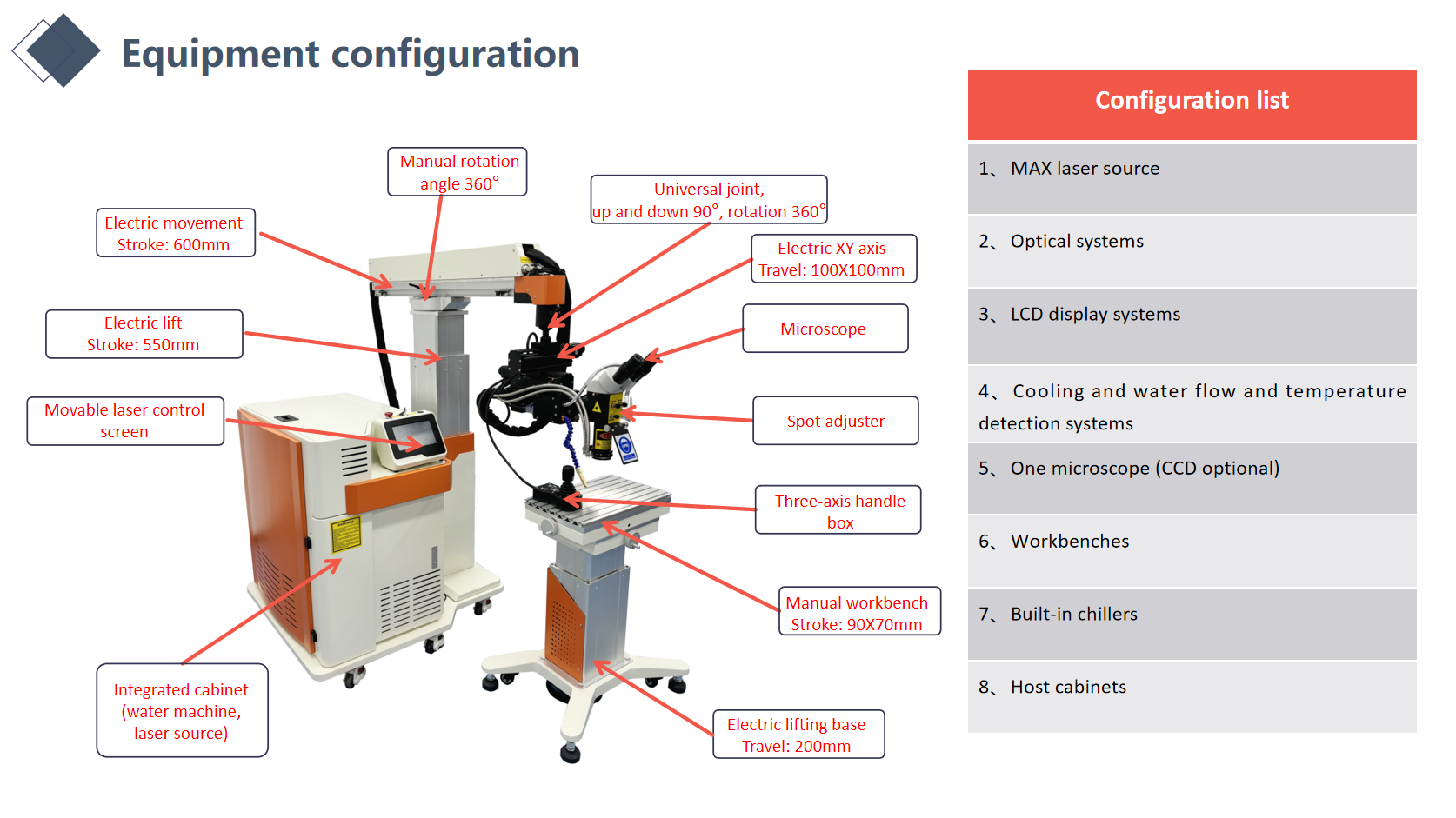

Get a free quote1. Fiber laser and QCW laser can be selected, with stable and reliable beams

2. Equipped with a dedicated chiller, which can meet long-term welding requirements and provide better stability;

3. Equipped with a three-dimensional load-bearing workbench base with electric lifting, the workbench moves using precision ball screws and high-precision straight guide rails, which are light and flexible, with precise positioning and a load-bearing capacity of 50 kg;

4. Equipped with a gas protection system, which effectively protects the product from argon gas protection during welding, maintains the product's true color and ensures welding quality

Video

Technical Parameter

Model | QCW-150W-DB | QCW-300W-DB | LX-1500W-DB |

Maximum laser power | 150W | 300W | 1500W |

Laser wavelength | 1080±10nm | ||

Laser fiber length | 10M | ||

Laser frequency | 1-30Hz | 1-30HZ | 1-25HZ |

Pulse Width | 1-20Ms | 1-20Ms | 1-60MS |

Light spot adjustment range | 0.2-3mm | 0.2-5mm | 0.2-5mm |

Aiming and positioning | Microscope (optional camera system) | ||

Chiller cooling power | 0.6P | 0.6P | CW1500 |

Rated power | 2.5KW | 3KW | 7KW |

Power demand | 220V±5V 50Hz/60A | ||

Three-dimensional load-bearing workbench | 50kg | ||

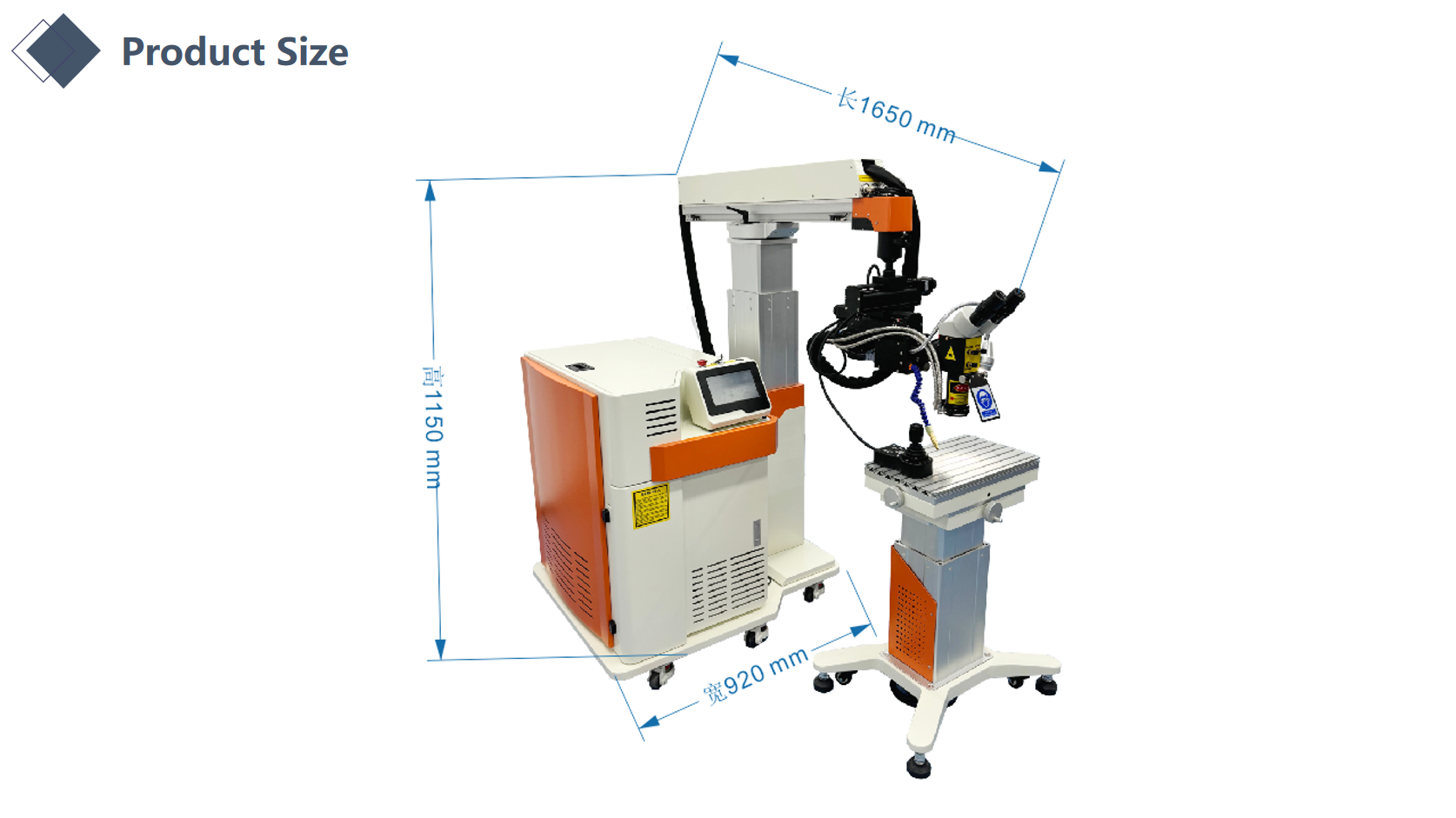

Overall dimensions/net weight | host:1650*920*1150mm | ||

| Three-dimensional load-bearing workbench:600*450*600mm | |||

Application

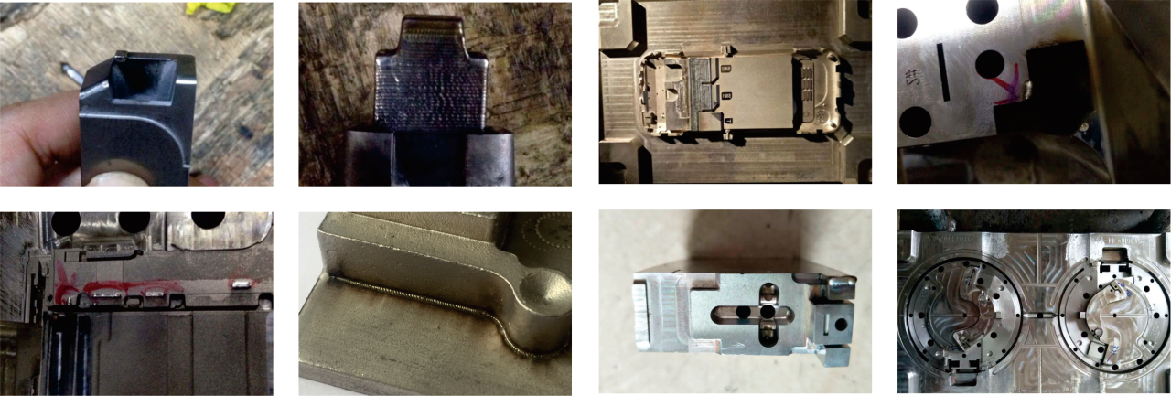

Suitable for large mold repair welding, mobile phone communications, jewelry crafts, electronic components, clocks, sensors, precision machinery, hardware, gas and automobile parts, etc., various metals and alloys.

Production Facility

QCW/Fiber Mould laser welding machine with crane

QCW/Fiber Mould laser welding machine with crane