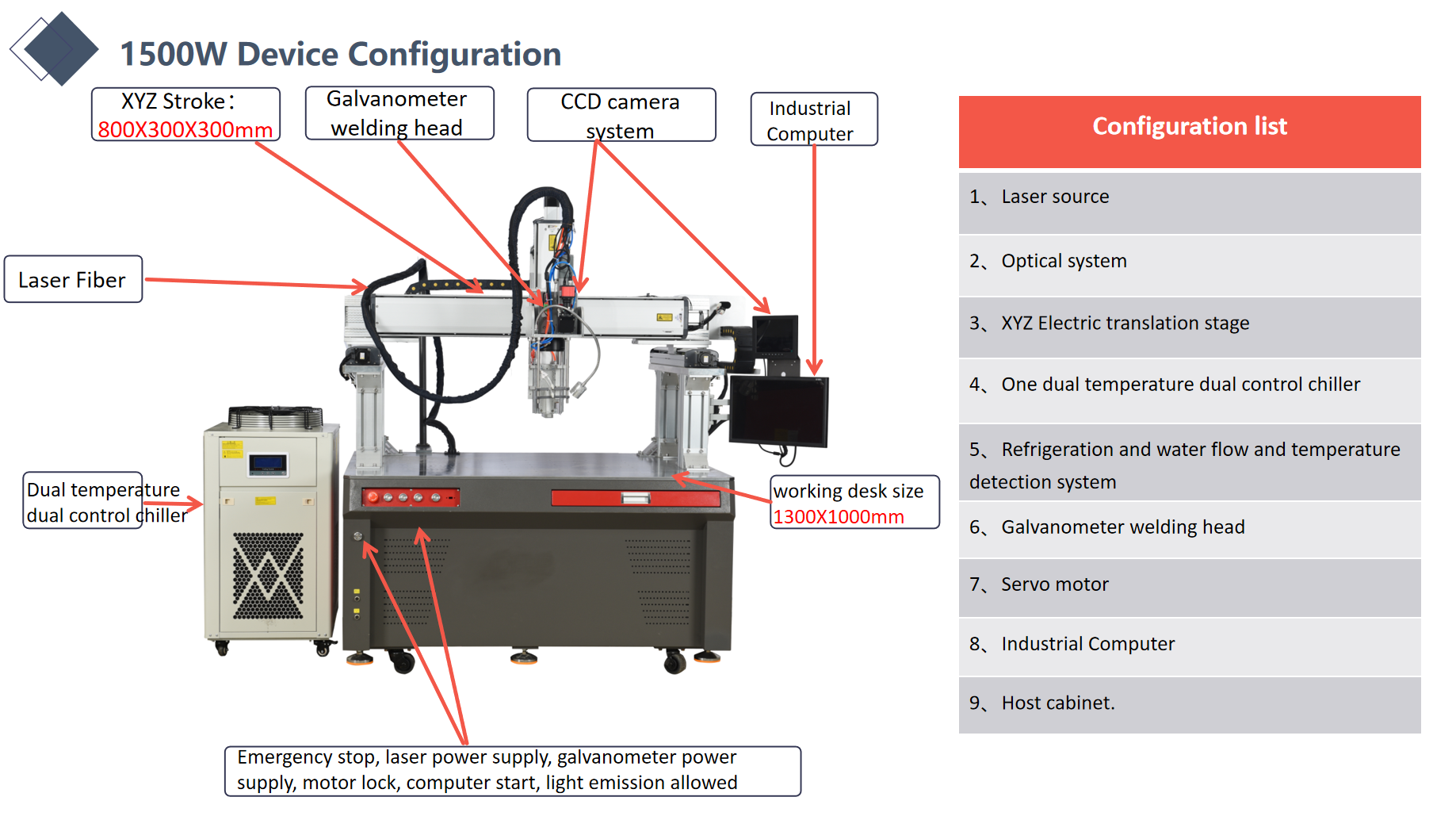

Gantry galvanometer laser welding machine

Get a free quote1. Adopt well-known brand laser, with high reflectivity, strong energy, high temperature resistance, corrosion resistance, and ultra-long service life;

2. Equipped with dual-temperature dual-control special chiller, which can meet long-term and high-power welding with better stability;

3. Fast speed, large depth, small deformation, beautiful weld, and less consumables;

4. Dedicated welding control system, high stability, easy to understand and learn, can realize continuous spot welding, straight line, circle, arc, etc., and arbitrary programming;

5. Adopt electric translation stage, with high repetitive positioning accuracy, fast welding speed, and fast processing speed;

6. Adopt high-speed scanning galvanometer for laser welding, which greatly improves production efficiency.

Video

Technical Parameter

| Laser wavelength | 1080nm | ||

| Laser fiber length | 10m | ||

| Max laser power | 1500w | 2000W | 3000W |

| Rated power | 7kw | 8KW | 10KW |

| Spot adjustment range | 0.1-5mm | ||

| Power Configuration | 220V/50Hz | 220V/50Hz | 380V/50Hz |

| Laser source frequency | 1-10000Hz | ||

| Cooling system | Cw1500 | Cw2000 | Cw3000 |

| Aiming and positioning | CCD or red light | ||

| Workbench parameters | |||

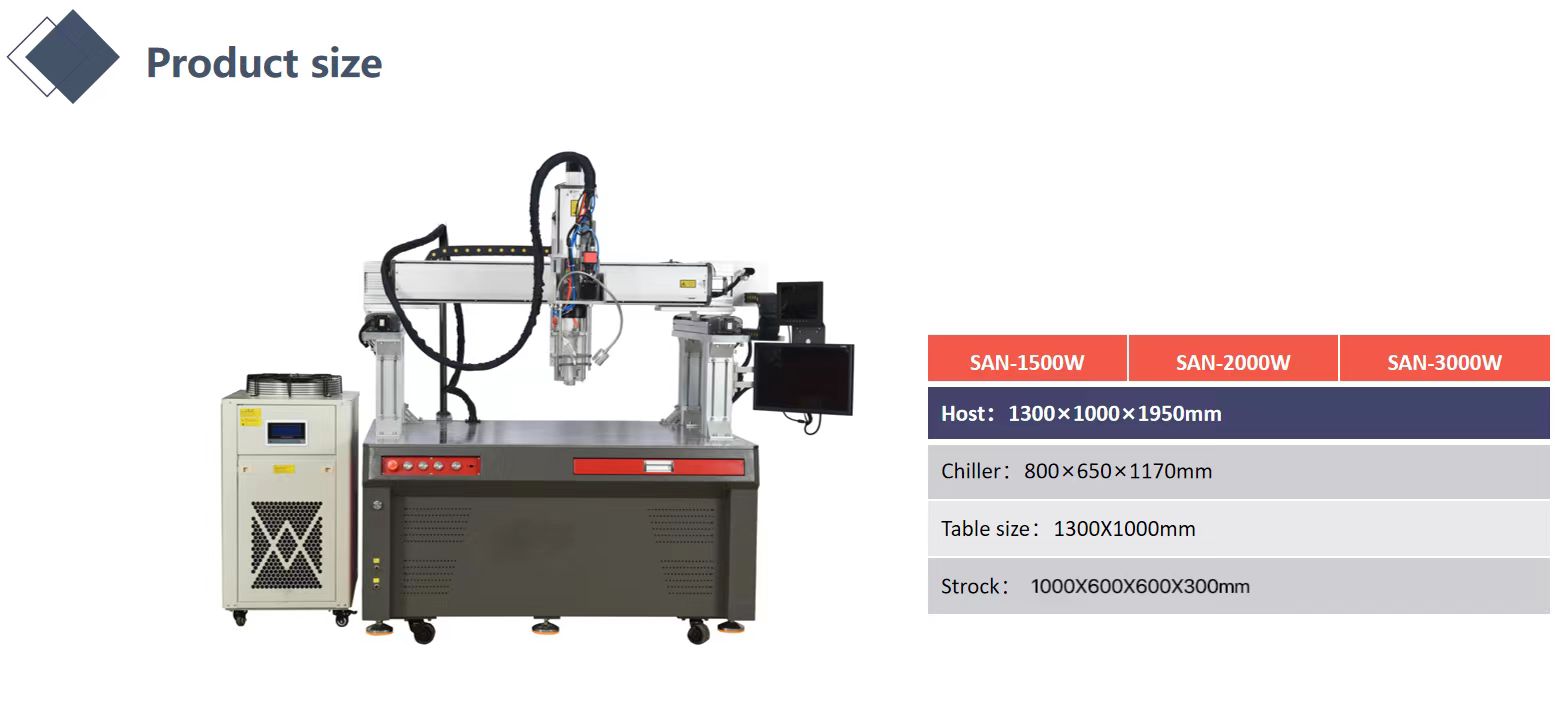

| XYZ Travel | 1000×600×600×300mm | ||

| Position accuracy | 0.05mm | ||

| Repeatability | 0.05mm | ||

| Maximum movement speed | 300mm/s | ||

| Optional components | Servo/stepper motor, automatic wire feeding, rotating axis, machine head swing, extended stroke | ||

Application

Weldable fine electronic components, new energy batteries, electronic components, vacuum cups, stainless steel products, sensors, tungsten wires, aluminum alloys, laptop casings, electrical accessories, etc.

Production Facility

Gantry galvanometer laser welding machine

Gantry galvanometer laser welding machine