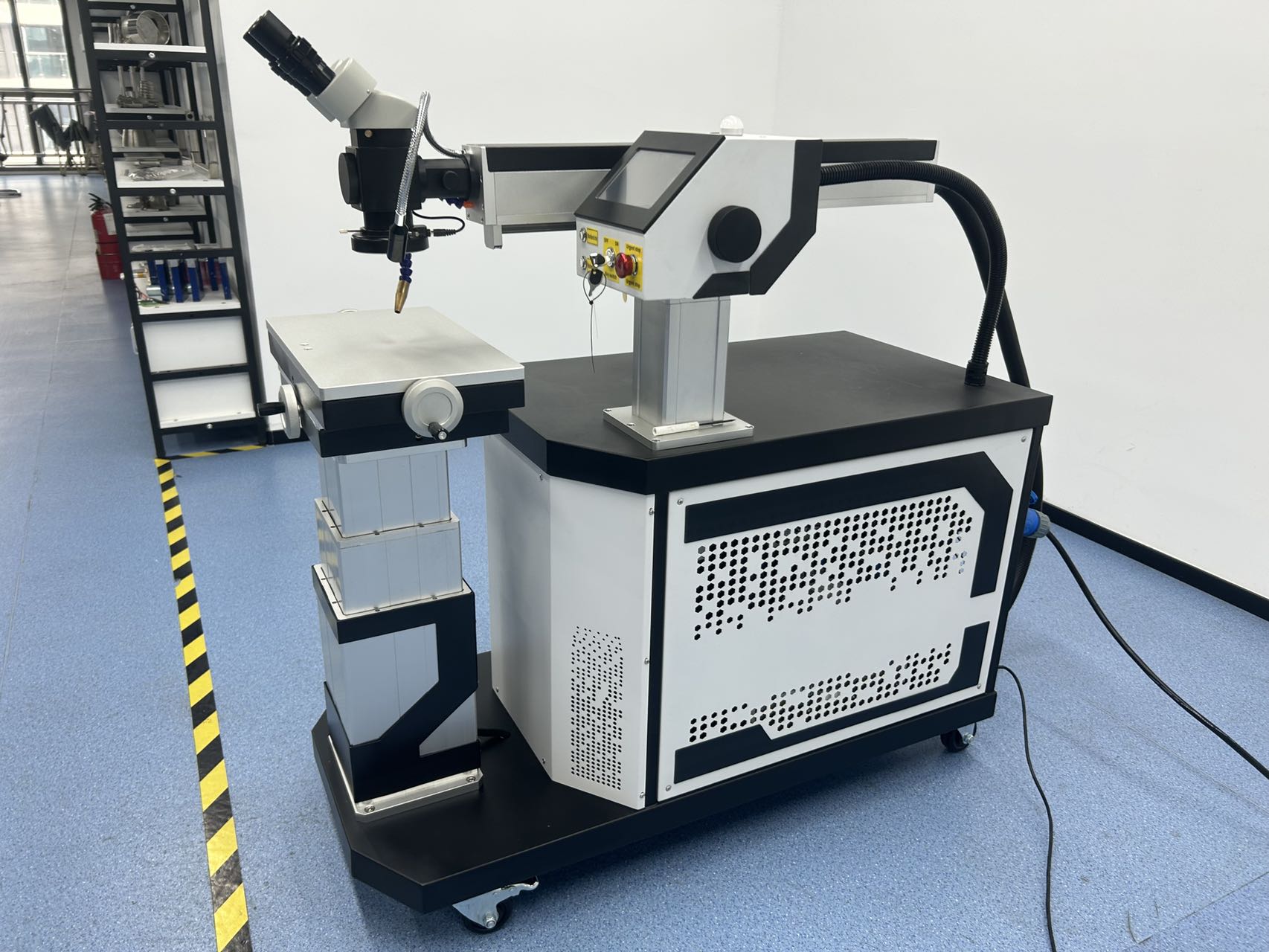

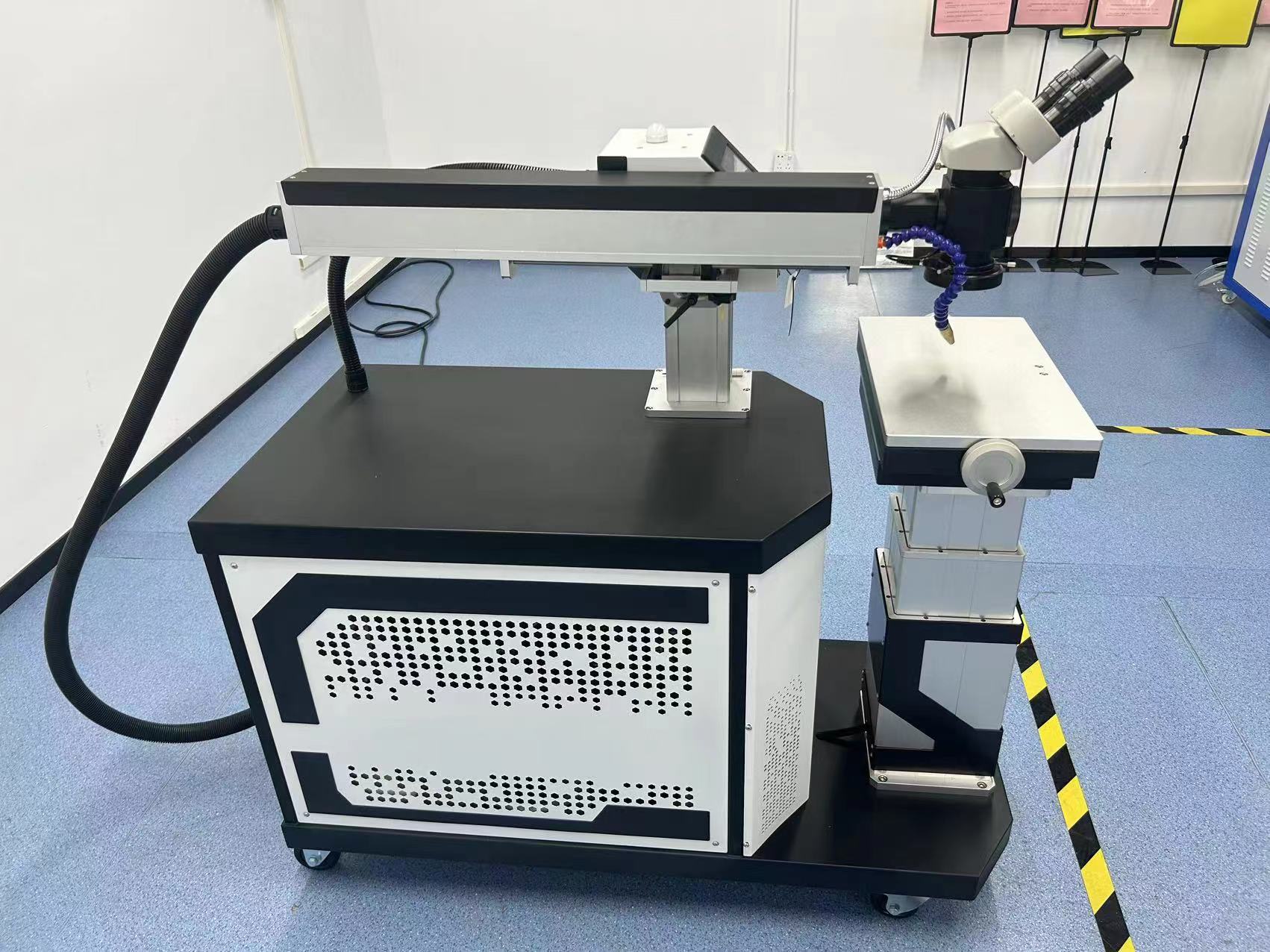

Mold repair laser welding machine

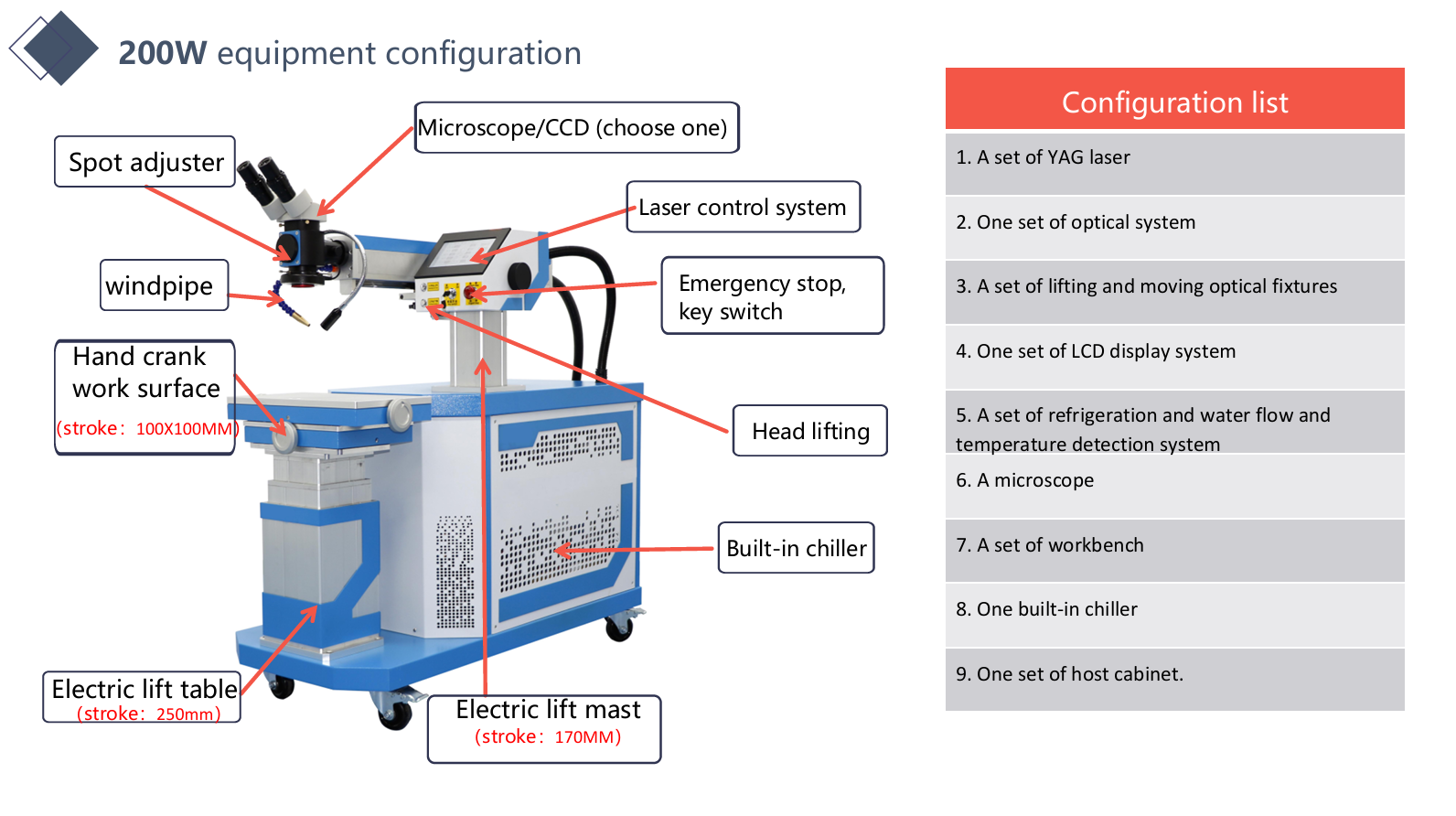

Get a free quote1. Imported ceramic focusing cavity is used, which has high reflectivity, strong energy, high temperature resistance, corrosion resistance and ultra-long service life;

2. Built-in special chiller can meet long-term requirements and better stability during welding;

3. Equipped with three-dimensional load-bearing table base electric lifting, the workbench moves with precision ball screw and high-precision straight guide rail,

which is light and flexible, with precise positioning and a load bearing capacity of 100 kg;

4. The laser head can slide back and forth, lift electrically, and the optical path can be adjusted up and down by 30°. The laser head can be easily rotated 120 degrees,

which is convenient for welding any side;

5. Equipped with gas protection system, it can effectively protect the product from argon protection during welding, maintain the original color of the product and ensure welding quality.

Video

Technical Parameter

| Model | SAN-200W |

| Laser wavelength | 1064nm |

| Focusing cavity reflector | Imported ceramic focusing cavity |

| Laser frequency | 1-20Hz |

| Pulse Width | 0.1-10ms |

| Light spot adjustment range | 0.2-2mm |

| Aiming and positioning | Microscope (optional camera system) |

| Chiller cooling power | built-in |

| Rated power | 7kw |

| electricity demand | 380V±5V 50Hz/40A ;220V±5V 50Hz/60A |

| Overall dimensions/net weight | 100×490×1240mm |

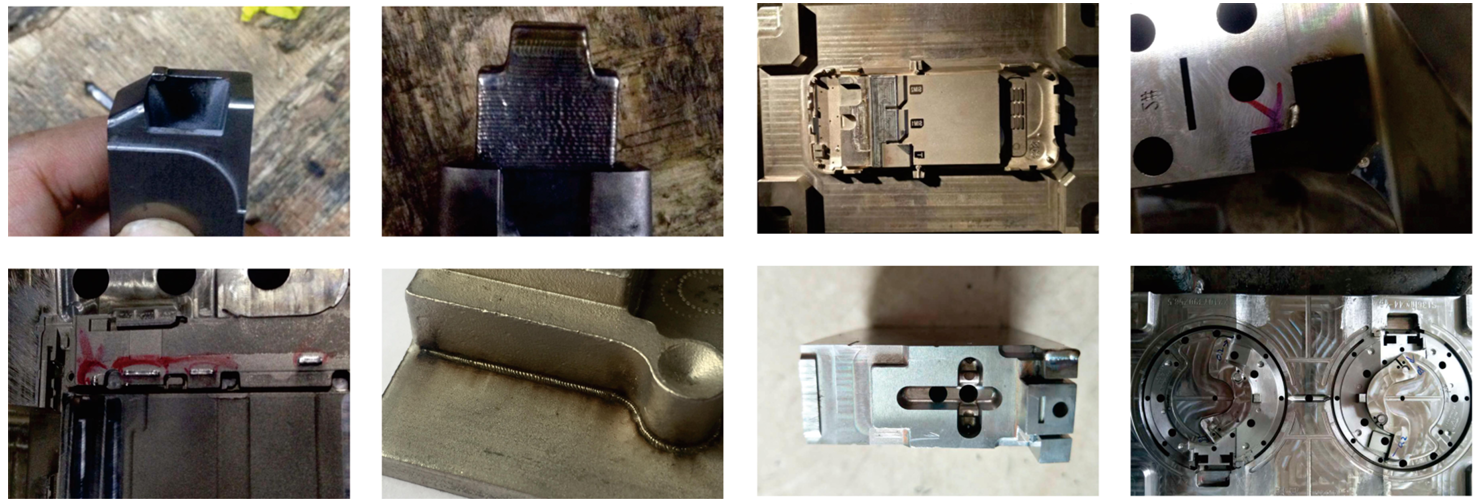

Application

Suitable for large mold repair welding, mobile phone communications, jewelry crafts, electronic components, clocks, sensors, precision machinery, hardware, gas and vehicle parts, etc., various metals and alloys.

Production Facility

Mold repair fiber laser welding

Mold repair fiber laser welding