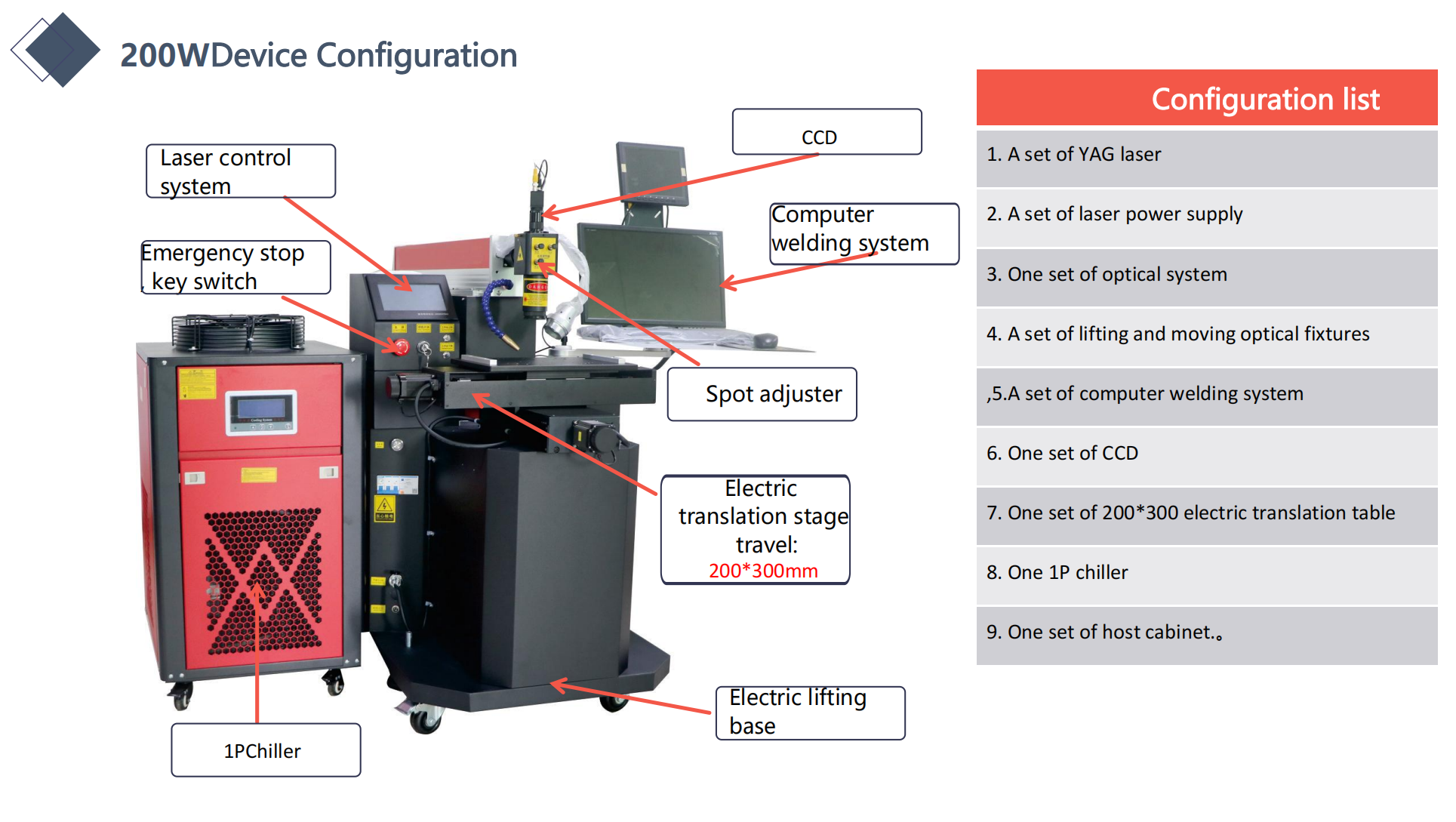

Automatic laser welding machine

Get a free quote1. Imported ceramic focusing cavity with high reflectivity, strong energy and long service life;

2. Specialized welding control system with extremely high stability, with full Chinese programming, LCD touch screen super control, easy to understand and learn,

can achieve continuous welding points, straight lines, circles, arcs, etc.;

3. Small light spot design has higher precision;

4. Strong scalability, can be combined with assembly lines, photoelectric detectors, starting fixtures and other devices for fully automatic unattended processing;

5. The electric translation table has long service life, high precision and fast processing speed.

![]()

Video

Technical Parameter

| Model | SAN-200W | SAN-400W |

| Laser wavelength | 1064nm | 1064nm |

| Focusing cavity reflector | Imported ceramic focusing cavity | Imported ceramic focusing cavity |

| Current adjustment range | 60-150A | 60-150A |

| Laser frequency | 1-20Hz | 1-30Hz |

| Pulse Width | 0.3-10ms | 0.3-10ms |

| Light spot adjustment range | 0.2-2mm | 0.3-3mm |

| Aiming and positioning | Microscope (optional camera system) | Microscope (optional camera system) |

| Chiller cooling power | 1.5P | 3P |

| Rated power | 8KW | 12KW |

| electricity demand | 380V±5V 50Hz/40A 220V±5V 50Hz/60A | 380V±5V 50Hz/40A |

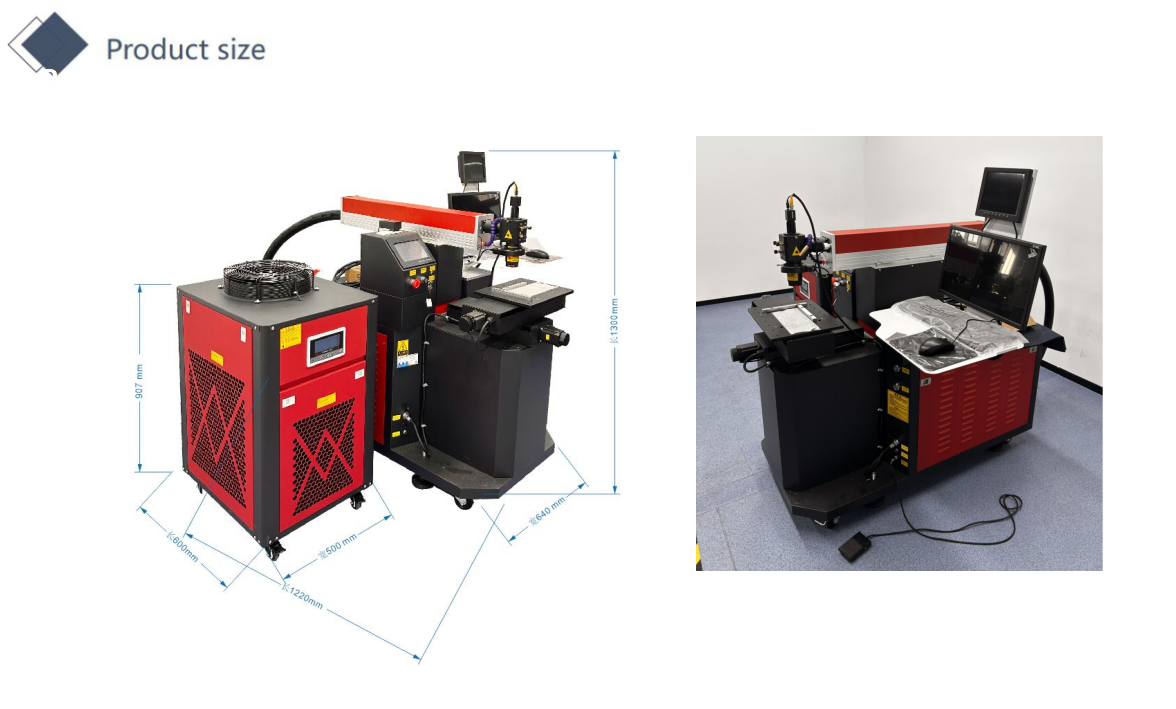

| Overall dimensions/net weight | Host:1220×640× 1300mm | Host:1220×640× 1300mm |

| Chiller:600×500×930mm | Chiller:850×600×1100mm |

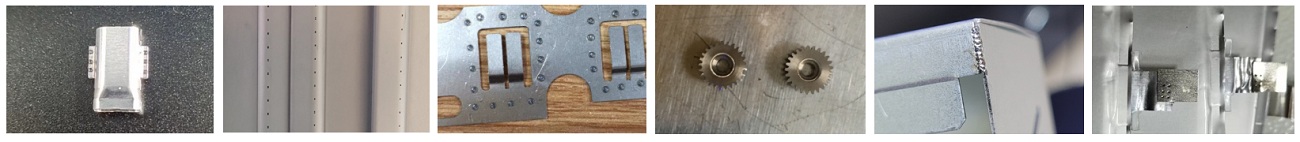

Application

Used in the welding of stainless steel, titanium steel, aluminum alloy, copper, galvanized sheet and other materials, used in electronic

appliances, confidential parts, automobiles, household appliances, tool processing, metal processing and other industries.

Production Facility

Automatic laser welding machine

Automatic laser welding machine