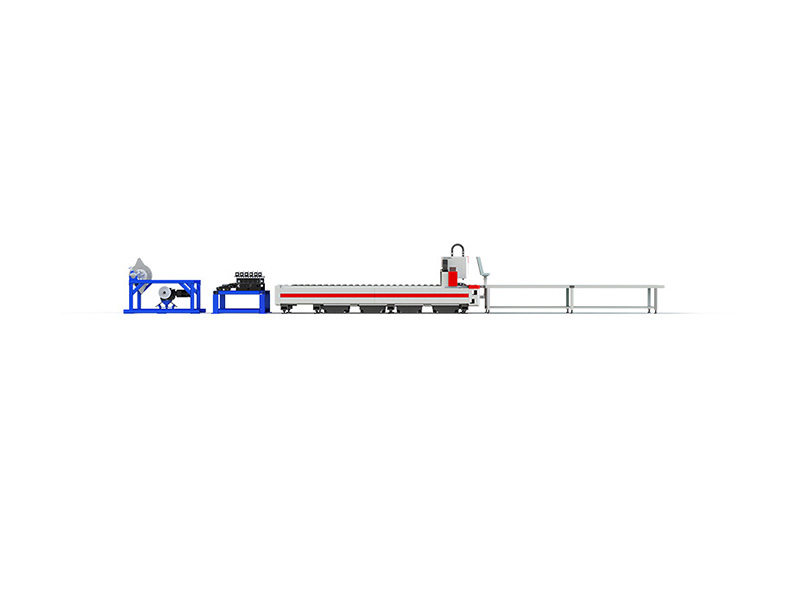

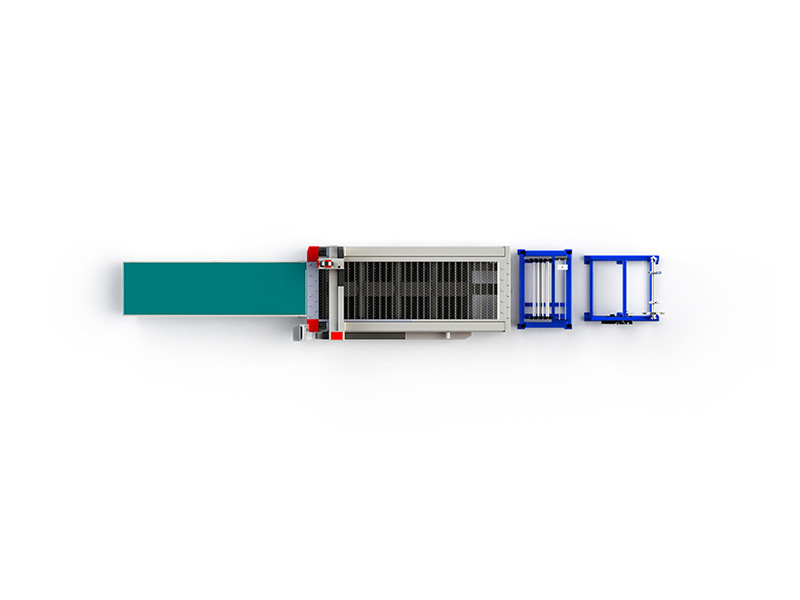

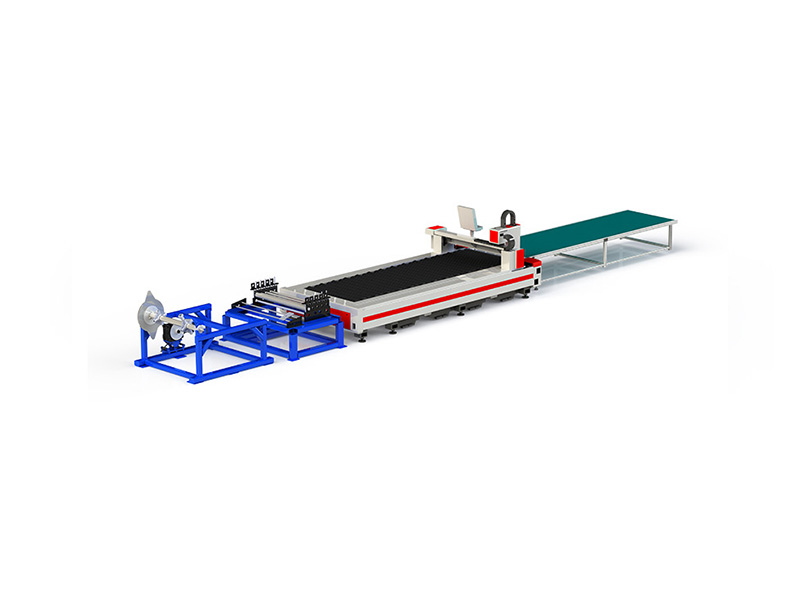

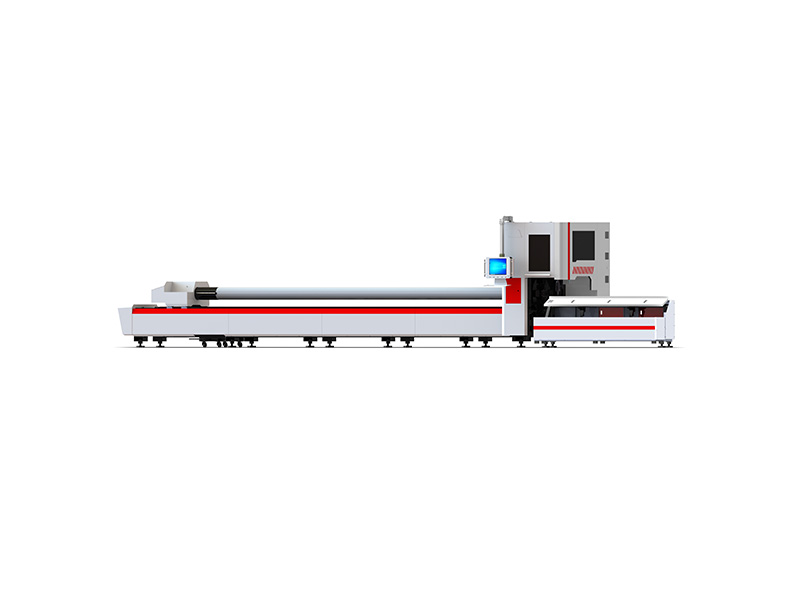

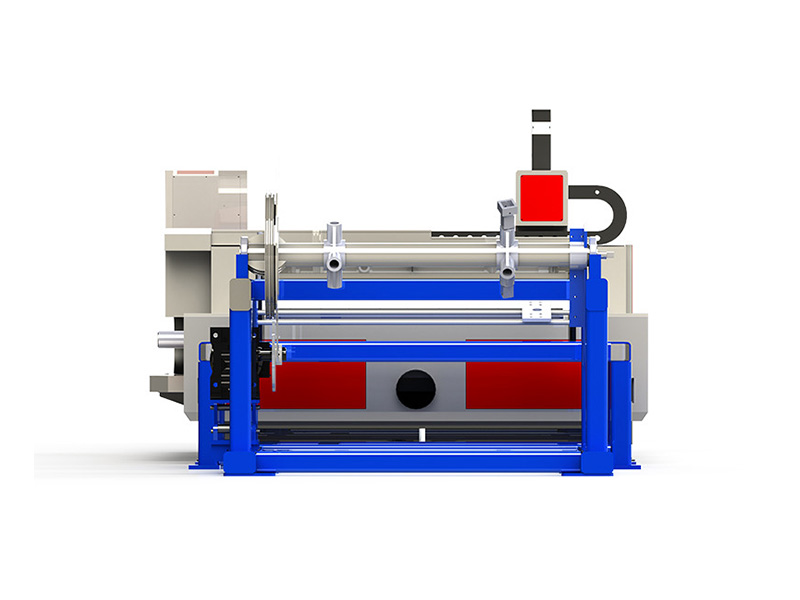

Coiled Metal Fiber Laser Cutting Machine

Get a free quoteThis metal coil feed Fiber Laser Cutting Machine revolutionizes traditional processing methods by combining unwinding, leveling, feeding, and cutting into a single automated processing line. This upgrade from standalone cutting enhances productivity through continuous cutting operations, significantly improving efficiency while reducing labor and material costs through intelligent automation.

Continuous Operation, High-Quality Cutting:

This machine supports 24/7 uninterrupted dynamic cutting, enabling seamless cutting while materials are fed. The material is continuously transported through unwinding, leveling, and feeding, ensuring a smooth and efficient cutting process that saves time and boosts productivity.

Low Investment, Intelligent Automation:

Replacing traditional methods such as press machines and molds, our solution eliminates the need for molds and requires minimal investment. The synchronized cutting and feeding process optimizes efficiency, resulting in lower operational costs and increased material utilization, ultimately reducing investment and mold consumption.

One-Pass Laser Cutting, High Precision:

Our laser cutting achieves high precision, with one-pass cutting eliminating the need for post-processing. This results in superior cut quality and minimal micro-cracking, enhancing the final product's overall quality.

High Material Utilization:

The use of continuous coil material minimizes waste typically associated with head and tail end losses. Optimized nesting further reduces material waste, ensuring maximum material utilization.

Flexibility in Production:

With the ability to modify 2D graphics through programming software, our system offers production flexibility to accommodate changing requirements. The automatic nesting feature reduces unnecessary waste, lowering production costs.

Video

Features & Advantages

Reduced Processing Costs:

Automation significantly reduces labor costs, and the laser cutting process itself requires fewer consumables. Combined with high material utilization, the overall cost of the production line is reduced.

Coil-to-Coil Cutting:

The production line is designed to work with continuous coil materials, allowing for uninterrupted coil-to-coil cutting. This efficient design eliminates the need for frequent material reloading, increasing overall productivity.

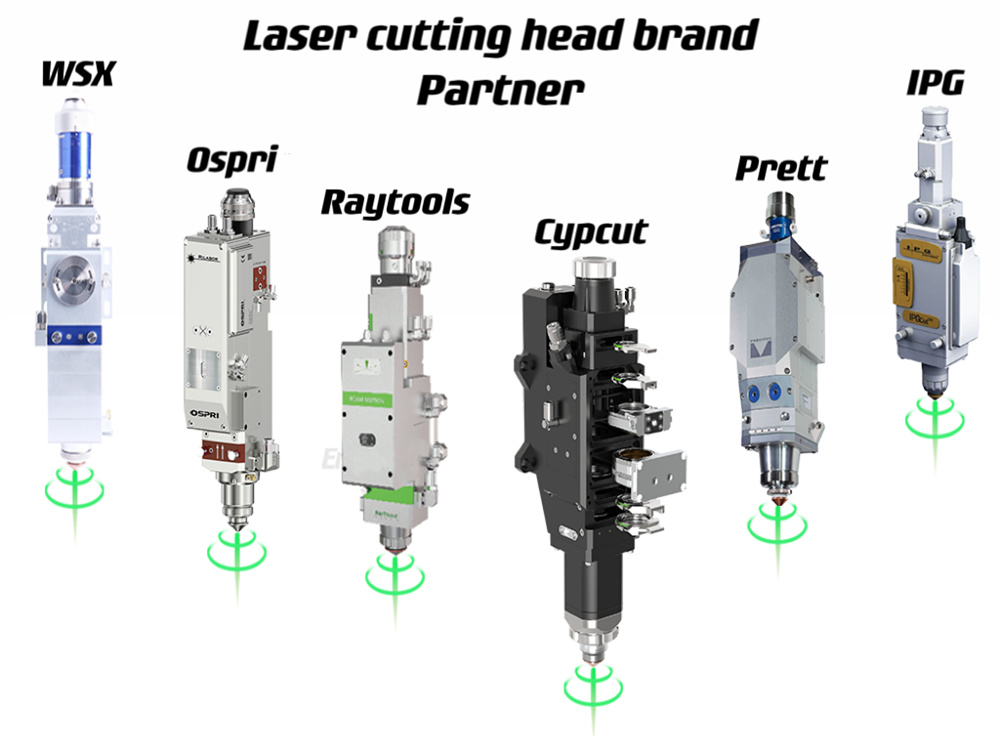

Advanced Cutting Technology:

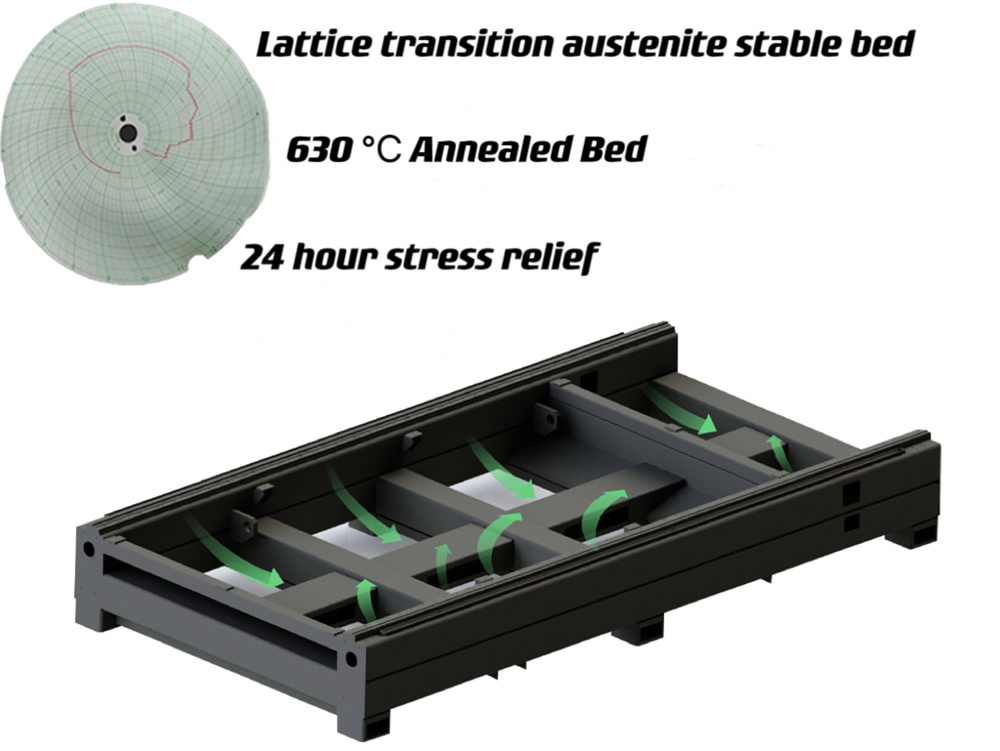

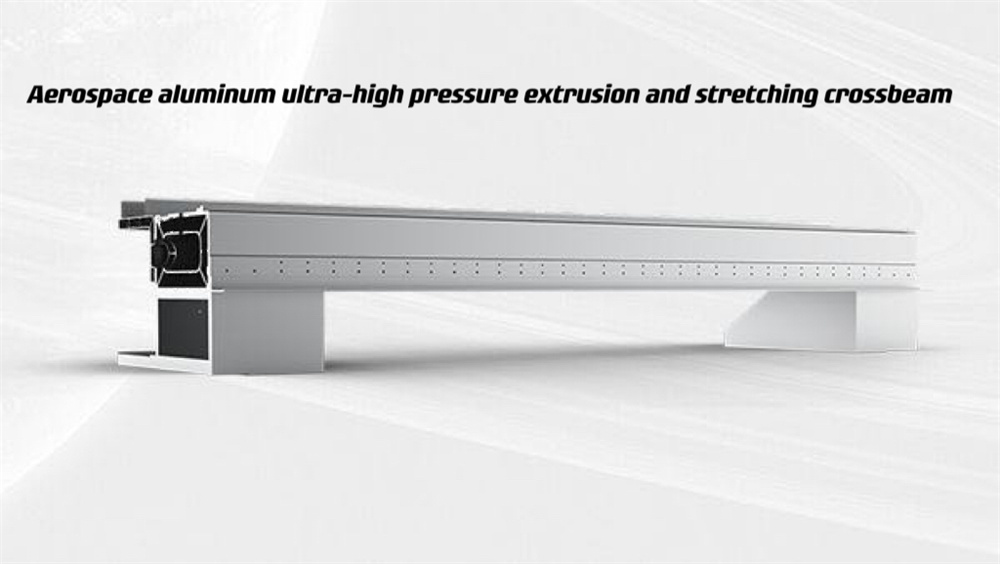

Our CNC-controlled laser cutting machine features a durable structure and synchronized motion for precise cutting. The use of bearings and reinforced gear drives enhances stability and quality.

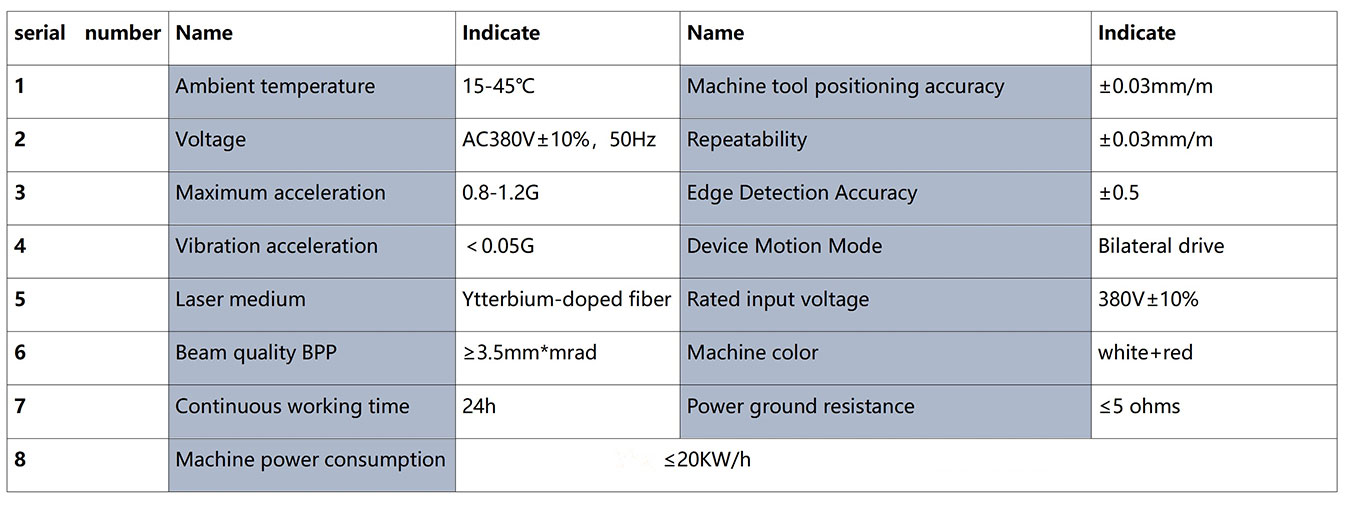

Technical Parameter

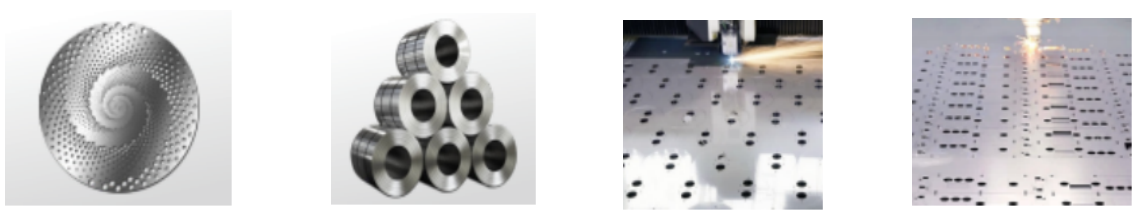

Application

Fully automatic feeding coil laser cutting machine is highly suitable for cutting and processing large scale thin coiled metal sheets, and can complete a series of full-process operations such as automatic uncoiling, leveling, feeding, cutting, palletizing and waste recycling of sheets. Automatically level the roll material, automatically and accurately feed the material, and cut efficiently. Save labor costs and improve production efficiency.

Coiled metal fiber laser cutting machine

Coiled metal fiber laser cutting machine