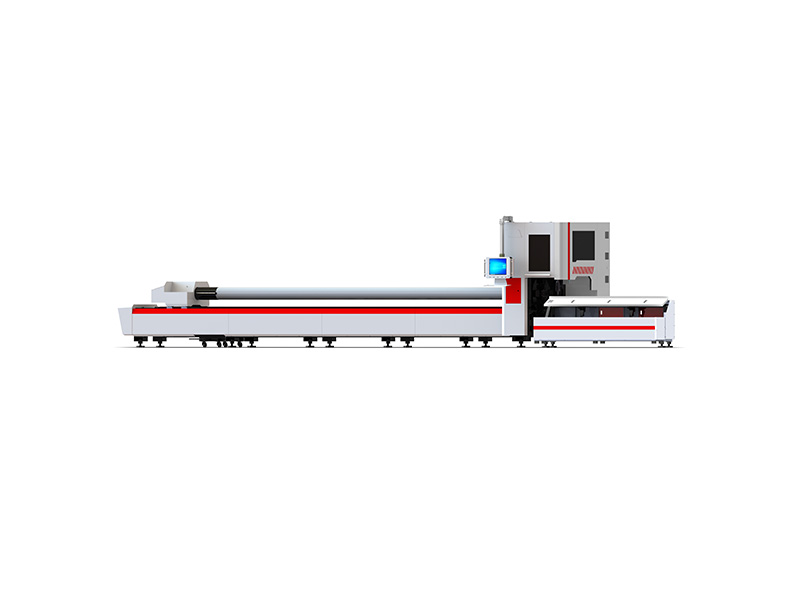

Fiber laser tube cutting machine

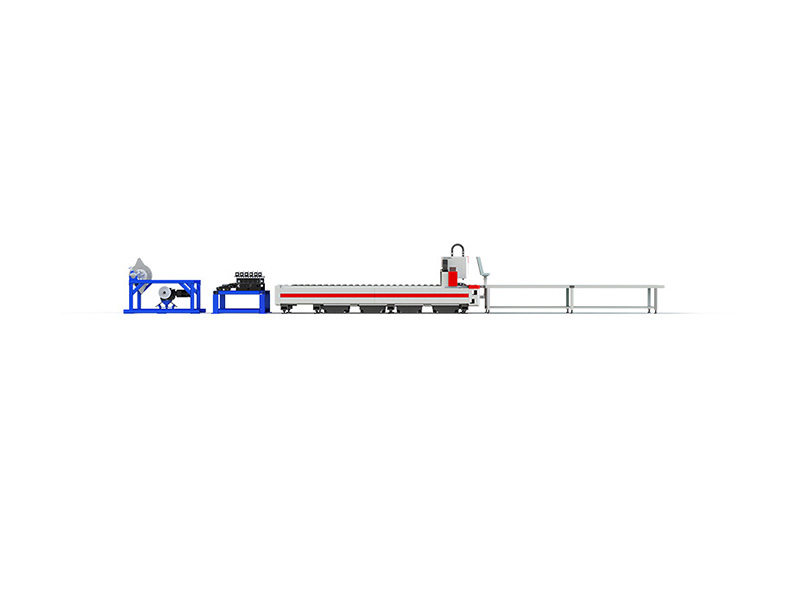

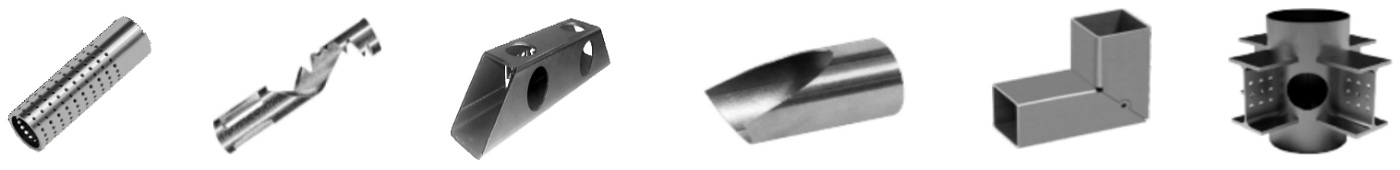

Get a free quoteHigh-speed fully automatic fiber laser pipe cutting machine, which can be used for cutting, beveling, perforating, and engraving various shapes of pipes made of various metal materials, round pipes, rectangular pipes, and irregular pipes. The new metal pipe laser processing production line not only achieves fully automatic production but also breaks through the limitations of flat cutting, enabling multi-dimensional cutting, making it an excellent choice for laser cutting of metal pipes!

1,High Safety – The chuck has a large inner hole, and automatic loading and unloading ensure high safety. The integrated built-in drive structure greatly enhances transmission accuracy and stability. Precision - Drum accuracy is 0.005mm, clamping accuracy is <0.1mm, and the dustproof effect is good. The gear is built-in to prevent cutting dust from entering, resulting in low noise and industry-leading gear grinding accuracy.

2,Low Inertia - Achieve high-speed processing to meet the fast cutting of small pipes. Minimal tailings - Can cut ultra-short tailings by limiting deep insertion and strong clamping before the card, using special friction surfaces for card claws to ensure that the pipes are not slipping. High Rigidity - The design of the barrel-type structure supports high rigidity and strong stability. Irregular Pipe Clamping - Supports multiple profile clamping to prevent pipes from slipping.

3,Industry Standard Bed, Long Service Life - High-strength cage-type structure welded bed - high-temperature annealing, long-term storage. Gantry processing - earthquake-resistant, torsion-resistant, deformation-resistant.

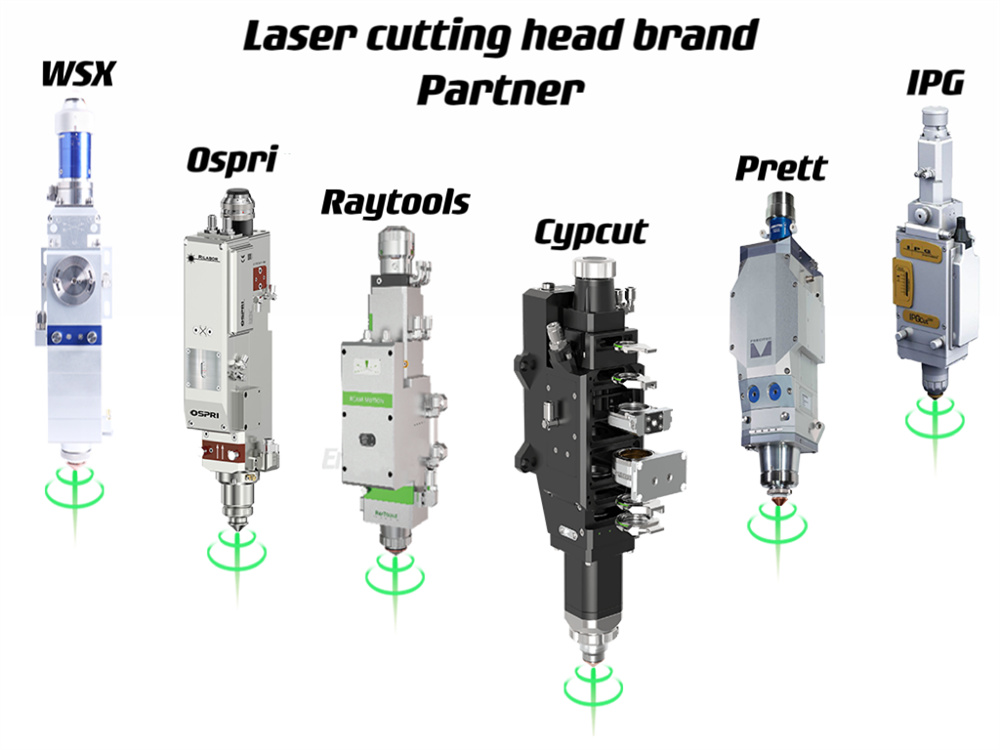

4,High-Quality Accessories, High Performance

5,High-Quality Drag Chain Cable - Resistant to bending and no breakage.The air pipe joint comes with a sealing ring, no need for sealing tape, reducing the possibility of impurities entering the air circuit.Professional Industrial Computer - Designed to withstand high temperatures, ensuring full-load work performance.

6,The main chuck is inserted into the front chuck to shorten the distance between the main chuck and the cutting head, ensuring cutting accuracy.

Video

Features & Advantages

1.Uses the industry-leading BOCAD dedicated pipe cutting CNC system, which can automatically measure pipe deviations, improve cutting accuracy, and support functions such as breakpoint positioning, continuous cutting, and corner process settings.Comes with specialized pipe cutting nesting software, supporting functions such as single-part, multi-part nesting, common edges, and automatic sorting.

2.The chuck's internal and pipe internal suction design reduces slag hanging in the pipe.

3.With follow-up rack, it can effectively support the tube during the tube cutting and blanking process to prevent the tube from sagging and swinging, thus ensuring the stability of cutting.

4.FSCUT software:fast typesetting, can achieve common edge cutting, saving time and materials.Support intelligent interconnection: semi-automatic/full-automatic feeder is optional to realize automatic production.

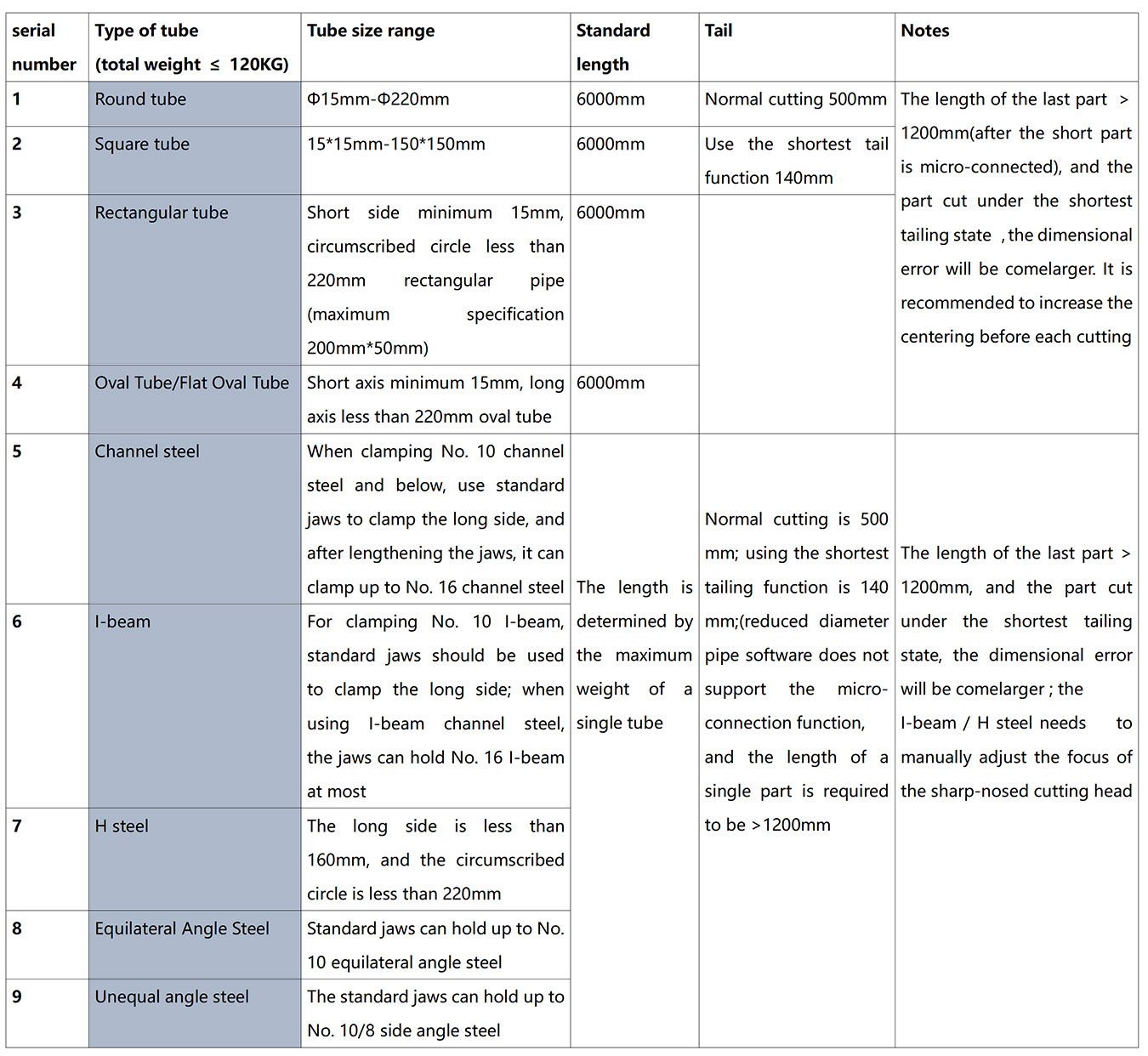

Technical Parameter

Application

Widely used in various mechanical manufacturing industries such as chassis cabinets, automotive parts, aerospace, household appliances, petrochemicals, kitchenware, office furniture, lighting fixtures, rail transportation, electronic and electrical products, building hardware, sports equipment, instruments, precision machinery, steel structures, elevator manufacturing, advertising, art, packaging, environmental protection equipment, and more.

Tube fiber laser cutter

Tube fiber laser cutter