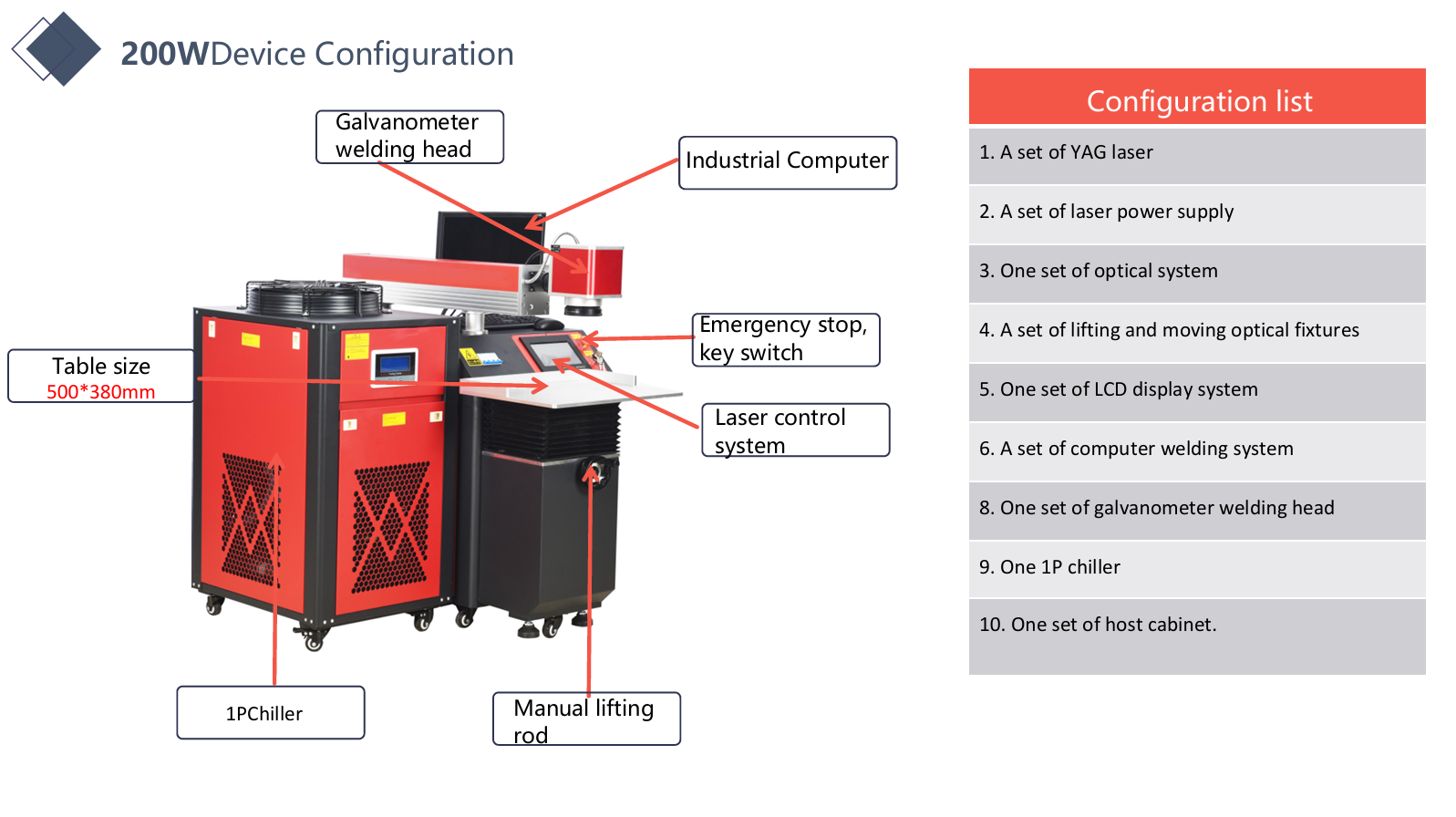

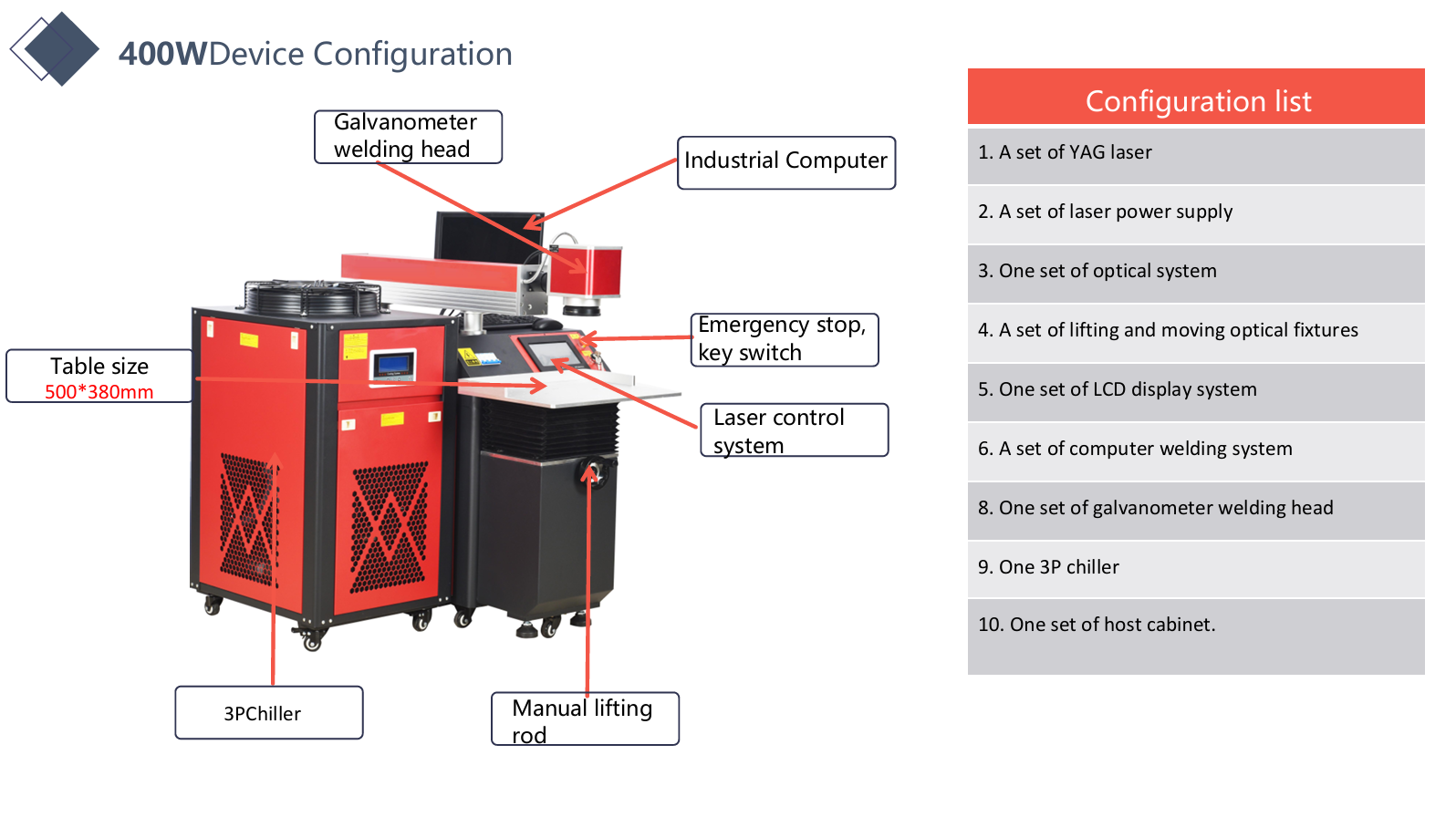

Galvanometer laser mold welding machine

Get a free quote1. Imported ceramic focusing cavity is used, which is corrosion-resistant, high-temperature-resistant and has a long service life;

2. Humanized design, ergonomic, no fatigue after long working hours, large work surface, movable up and down, surrounding baffle design,

convenient processing;

3. High-speed scanning galvanometer is used for laser welding, which greatly improves production efficiency;

4. Digital galvanometer interface, strong anti-interference ability and better stability.

Video

Technical Parameter

| Model | 200W | 400W |

| Laser wavelength | 1064nm | 1064nm |

| Focusing cavity reflector | Ceramic focusing cavity | Dual lamp spotlight cavity |

| Current adjustment range | 60-150A | 60-150A |

| Galvanometer range | 50*50mm | |

| Laser frequency | 1-20Hz | 1-30Hz |

| Pulse Width | 0.3-10ms | 0.3-10ms |

| Spot adjustment range | 0.2-2mm | 0.2-3mm |

| Aiming and positioning | Red light | Red light |

| Chiller cooling power | 1P | 3P |

| Rated power | 8KW | 12KW |

| electricity demand | 220V±5V 50Hz/60A 380V±5V 50Hz/40A | 380V±5V 50Hz/40A |

| External dimensions | Host:1030×640×1050mm | Host:1030×640×1050mm |

| Chiller:600×500×907mm | Boom:850×600×1100mm | |

Application

Suitable for delicate electronic components, 3C batteries, mobile phone cases, electronic components, vacuum cups, stainless steel products, sensors, tungsten wires, aluminum alloys, laptop computer cases, electrical accessories, etc.

Production Facility

Galvanometer laser mold welding machine

Galvanometer laser mold welding machine