- No.609, Centre Of Huijin Nanxiang, Yinxiang Road, Nanxiang Town, Jiading District, Shanghai, China

- sherry@sanmachines.com

- +86-18616767021

Pulse Laser Cleaning vs. Fiber Laser Cleaning: Differences & Recommendations

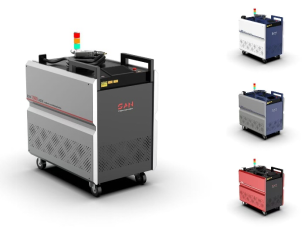

In the field of laser cleaning technology, two primary solutions stand out: pulse laser cleaning machines and fiber laser cleaning machines. Both technologies offer effective cleaning for various industrial applications, but their differences make them suitable for different use cases. Understanding these differences can help businesses choose the right machine for their specific needs.

Pulse Laser Cleaning Machine

pulse laser cleaning machines utilize a solid-state laser source to generate high-energy pulses for removing rust, paint, coatings, and contaminants from surfaces. Key characteristics of pulse laser cleaning include:

Lower Cost: laser cleaning systems are generally more affordable than fiber lasers, making them a cost-effective choice for small to medium-sized businesses.

Good for Delicate Surfaces: The pulse laser operates at a lower energy density, which minimizes heat damage and makes it suitable for cleaning sensitive materials such as historical artifacts, electronics, and soft metals.

Moderate Maintenance: While lasers require periodic maintenance, they remain a reliable option for various cleaning applications.

Fiber Laser Cleaning Machine

Fiber laser cleaning machines use advanced fiber laser technology, known for its efficiency, precision, and longevity. They are widely used in industrial environments where high-speed, deep cleaning is required. Key advantages of fiber laser cleaning include:

Higher Efficiency: Fiber lasers deliver higher power and faster cleaning speeds, making them ideal for heavy-duty industrial applications such as automotive, shipbuilding, and machinery maintenance.

Low Maintenance & Long Lifespan: Fiber laser systems have fewer consumable components and require minimal maintenance, resulting in lower operational costs over time.

Environmentally Friendly: With no chemical consumables and minimal waste, fiber laser cleaning is an eco-friendly solution that aligns with modern sustainability practices.

l Which One Should You Choose?

When selecting between YAG pulse laser cleaning and fiber laser cleaning, consider the following factors:

Budget: If cost is a primary concern, pulse laser cleaning machines may be the better choice due to their lower initial investment.

Material Sensitivity: For delicate or heat-sensitive materials, pulse laser cleaning is preferable due to its lower heat impact.

Cleaning Speed & Efficiency: If you need a high-speed, industrial-grade solution with minimal maintenance, fiber laser cleaning is the best option.

l Conclusion

Both pulse laser cleaning machines and fiber laser cleaning machines have their distinct advantages, making them suitable for different industries and applications. If you need assistance selecting the right laser cleaning machine for your business, feel free to contact us. Our team of experts is ready to provide professional guidance and recommend the best solution for your specific requirements.

For more information about our laser cleaning machines, visit our website or reach out to us directly!

Get professional support now

Related product links

Welder News

Welder News