-

What type of welder is used in jewelry making?

When making jewelry, welding technology plays a vital role. It connects the various parts of jewelry as it affects the quality and durability of jewelry. Therefore, choosing the right welding equipment is crucial. It needs to be able to precisely connect various materials. It als...Mar 04,2025Learn more -

Recommended Jewelry Laser Welding Machine!

When you are looking for jewelry laser welding machines, we highly recommend SAN LASER's jewelry laser welding machines. This high-performance equipment provides jewelry designers and manufacturers with unparalleled precision and efficiency. It meets the most demanding proces...Mar 04,2025Learn more -

Some common questions about pulse laser cleaning machine!

With the continuous development of the laser industry, SAN LASER is also constantly innovating and developing. With the continuous updating of cleaning methods. Laser cleaning has gradually become a major development trend. Many people have heard of laser cleaning, but they don’t...Feb 28,2025Learn more -

Difficulties and solutions for stainless steel welding!

When using traditional welding methods, we often need some help. Fortunately, we have laser welding technology that can solve these problems. Next, we will highlight these difficulties and show how laser welding can alleviate them.Problem 1: Heat-Affected Zone (HAZ)The HAZ can so...Feb 28,2025Learn more -

How to extend the life of the laser welding machine?

The laser welding machine uses a continuous fiber laser with a wavelength of 1080nm generated by the laser. After beam expansion, reflection and focusing, the light beam is irradiated to the surface of the workpiece, and the surface heat diffuses to the inside through heat conduc...Feb 24,2025Learn more -

In-depth comparison between laser welding and tig mig welding!

The laser welding speed is 5-10 times faster than the traditional welding speed. It can help you to save at least two welders a year. Easy to operate, no need welding work license, new comer can also weld products beautifully. The welding seam is smooth and beautiful, which reduc...Feb 18,2025Learn more -

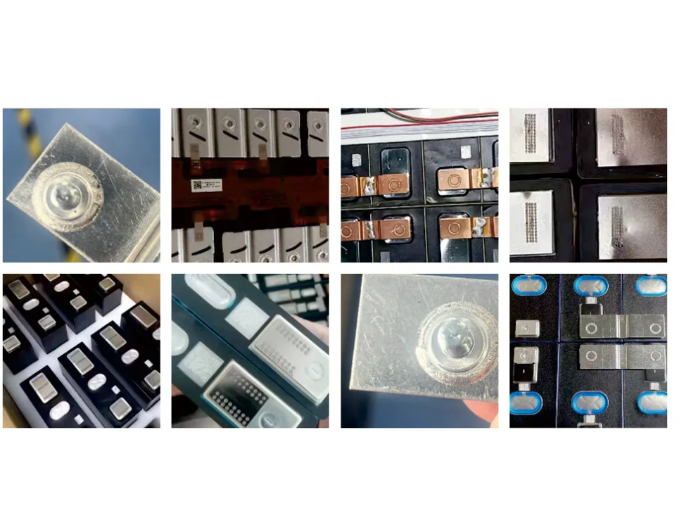

How does laser welding of cells for battery packs work?

Battery laser welding processes are generally similar to other laser welding methods. Both automated and handheld laser welding are used in battery pack manufacturing. Before welding, the battery cells are cleaned and properly positioned. Be aware that contaminants may affec...Feb 17,2025Learn more -

Battery Laser Welding for Battery Pack Manufacturing!

This battery laser welding machine is one of the best laser welding machines for battery backplanes. The machine is equipped with an articulated galvanometer system. Articulation means moving the laser gun on the X-axis and Y-axis. In this way, you can control the laser welding a...Feb 12,2025Learn more -

Why is laser paint removal safe?

As we all know, laser paint removal is a modern technology. It is the most effective and safest option currently available. There are many reasons why it is safe. In this section, we will tell you six reasons why laser paint removal is safe.Non-contact processLaser paint removal ...Feb 11,2025Learn more -

Application of pulse laser cleaning machine!

Application materials: Pulse laser cleaning machine can clean most metal and non-metal materials. Generally used for metal materials. For example, ordinary iron, copper, aluminum alloy, stainless steel, etc.Some metals come into contact with moisture and oxygen in the air, underg...Feb 11,2025Learn more

Fiber Laser Welding Machine

-

QCW/Fiber Mobile mold repair laser welding machine

-

QCW/Fiber Mould laser welding machine with crane

-

Handheld fiber laser welding machine

-

Fiber transmission laser welding machine

-

Jewelry welding

-

Handheld galvanometer laser welding machine for Battery Weld Repairs

-

Galvanometer laser mold welding machine

-

Mold repair fiber laser welding

-

Intergrated boom laser welding machine

-

Automatic laser welding machine

-

Automatic platform laser welding machine

-

Gantry galvanometer laser welding machine

-

Robot welding machine

-

Handheld fiber laser cleaning machine

-

Pulse laser cleaning machine

Welder News

Welder News