- No.609, Centre Of Huijin Nanxiang, Yinxiang Road, Nanxiang Town, Jiading District, Shanghai, China

- sherry@sanmachines.com

- +86-18616767021

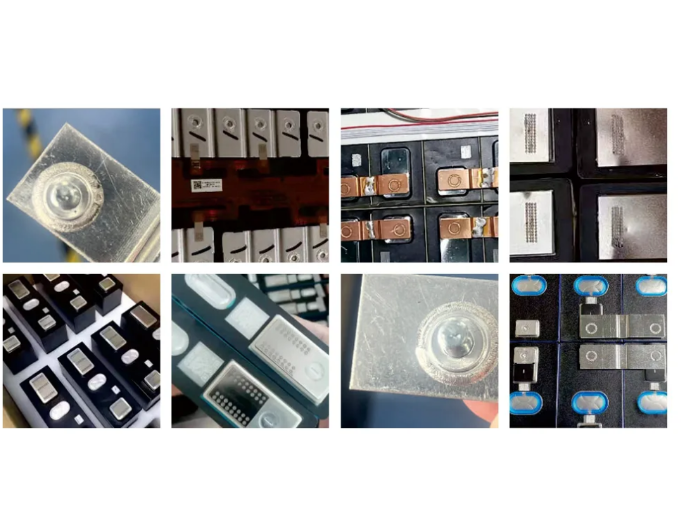

How does laser welding of cells for battery packs work?

Battery laser welding processes are generally similar to other laser welding methods. Both automated and handheld laser welding are used in battery pack manufacturing.

Before welding, the battery cells are cleaned and properly positioned. Be aware that contaminants may affect the quality of the laser weld. Next, the laser beam is aimed at the location where the battery and connector are to be connected.

When the laser hits the surface, the target area melts. After cooling, the substance hardens and firmly connects the connector and battery cell. Due to the high precision of the laser, the weld cools quickly, so the surrounding area does not feel much heat.

There are three components that play a vital role in laser welding. First, the laser source produces the laser beam. Lasers are available in continuous and pulsed types. Pulsed laser beams are widely used in battery laser welding. Second, the focusing optical system mainly amplifies and focuses the laser beam at a precise location. Finally, the cooling system manages the heat required for the process.

Tips for Laser Welding of Battery Packs

As we all know, battery packs are made up of multiple battery cells. Precise laser welding ensures that your battery performs well and does not generate excessive heat. If the welding is not done properly, the connection may become weak, the battery may die, or it may become overheated. Therefore, it is important to follow the correct steps to achieve the best results.

Tip #1. Choose the right clamping method

The clamps usually hold the battery cells firmly in place during the welding process. Therefore, it is important to choose the right clamping method. This will ensure that there will be no misalignment or weak welds. When this happens, make sure that the clamps do not put too much pressure on the battery cells, otherwise it may damage the battery cells.

Tip #2. Ensure the cells are placed correctly

Before welding, you should also ensure that the battery cells are arranged correctly. Improper arrangement is the main reason for poor welding. Ultimately, your battery pack may not work as expected, so it is important to place the battery cells in the correct position.

Tip #3. Optimize the bushing design

Busbars are also connectors in battery packs. They are mainly responsible for conducting and distributing current. Overall, busbars ensure reliable power flow. Therefore, it is important to optimize the busbar design before welding.

Copper is a good choice for this application. There are many reasons why this material is popular. First, it is lightweight, and second, it is highly conductive. However, the bushing must be thick enough to handle the current.

Tip #4. Make a plan for how to handle the batteries

Batteries are sensitive and can be easily damaged if not handled properly. Therefore, you can make a plan to handle the entire packaging process. In this case, you can adopt some techniques to do the job more professionally. Safe lifting techniques or professional storage are typical steps that can be taken during the welding process. However, if you run a business, make sure everyone is well trained.

Tip #5. Ensure the quality of battery laser welding is properly assured

Finally, QA, or quality assurance, is another key job in battery laser welding. You can ensure quality in many ways. One of the best ways is to conduct regulatory inspections. Use appropriate testing methods to evaluate the quality of each weld.

Related product links

Welder News

Welder News