- No.609, Centre Of Huijin Nanxiang, Yinxiang Road, Nanxiang Town, Jiading District, Shanghai, China

- sherry@sanmachines.com

- +86-18616767021

In-depth comparison between laser welding and tig mig welding!

The laser welding speed is 5-10 times faster than the traditional welding speed. It can help you to save at least two welders a year. Easy to operate, no need welding work license, new comer can also weld products beautifully. The welding seam is smooth and beautiful, which reduces the subsequent grinding process and saves time and cost.

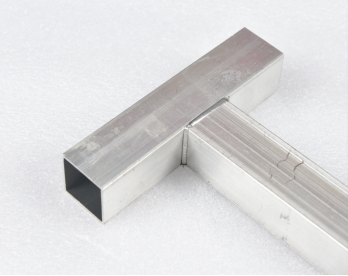

No deformation, no weld scar, welding firmly.

1. Principles of laser welding and argon arc welding

Laser welding is a process that uses the energy of a laser beam to generate high temperatures in the welding area, thereby melting the material and forming a weld. The laser has high energy density, fast welding speed, high precision, and no contact with the heat-affected zone.

Argon arc welding uses the high temperature generated by inert gases such as hydrogen under the action of an arc to melt the metal and form a weld. Compared with laser welding, argon arc welding can weld thicker materials, but the speed is slower and requires the use of high-power equipment.

2. Comparison of welding speed

The welding speed of laser welding is much faster than that of argon arc welding, usually 5 times that of argon arc welding. Because the energy density of the laser is very high after focusing, the temperature changes rapidly during the welding process, so the welding can be completed quickly, far exceeding the capacity of argon arc welding.

3. Comparison of weld quality

Because laser welding has a higher energy density and a faster welding speed, fewer pores and heat-affected zones are generated during the welding process, resulting in higher quality welds.

Argon arc welding requires gas protection, which can effectively control oxides and ensure the stability of the weld quality. However, due to improper gas flow control, bubbles and defects are easily generated.

4. Application scenarios of laser welding and argon arc welding

Since laser welding can weld quickly and ensure the quality and accuracy of welds even in difficult welding work, it has been widely used in highly demanding fields such as industry and aerospace.

Argon arc welding works better when welding thicker workpieces and can weld a variety of materials. Therefore, it is still a common method in the fields of ships, pipelines, petrochemicals, pressure vessels, etc.

[Conclusion]

Laser welding and argon arc welding are both commonly used metal material welding methods, and each has its own advantages and disadvantages in different application scenarios. This article compares the principles, welding speed, weld quality, etc. of the two welding methods, and introduces the application scenarios of laser welding and argon arc welding, hoping to help readers understand the difference between the two.

Related product links

Welder News

Welder News