-

Machine structure of continuous laser welding machine!

Laser welding machine generally consists of five parts, 1::Laser welding host: The laser welding host mainly generates the laser beam used for welding, which is composed of laser generator, optical path part, power supply, control system and other main parts, 2:&nb...Nov 21,2024Learn more -

Introduction to mold laser welding machine!

Application scope of mold laser welding machine Mold laser welding machine and repair machine use 50-60 Rockwell temperature to repair and weld cracks, broken corners, edges and damaged sealing edges of molds, precision injection molding, die casting, stamping, stainless ste...Nov 21,2024Learn more -

What materials can be welded by laser welding machine?

Laser welding machine is a machine used for laser material processing. According to its working mode, it is divided into laser mold welding machine, automatic laser welding machine, laser spot welding machine, and fiber transmission laser welding machine. What materials can be we...Nov 21,2024Learn more -

Working principle and welding characteristics of mold welding machine!

The laser mold welding machine was first called a laser welding machine. During the development process, the mold laser welding machine was also called a mold laser repair machine. However, they all use conventional laser welding methods to achieve local heating of small areas by...Nov 21,2024Learn more -

Application of fiber laser welding machine in mobile phone parts!

In the field of fiber laser welding machine manufacturing, Tongfa Laser relies on more than ten years of accumulation and development of laser processing technology, deeply grasps the major needs of transformation and upgrading, and helps users reduce energy consumption, improve ...Nov 20,2024Learn more -

How to use mold laser welding machine?

With the continuous development of industrial technology, mold laser welding machine has become an indispensable and important technology in modern industry. Laser welding technology has many advantages such as fast welding speed, high welding efficiency and good welding quality,...Nov 20,2024Learn more -

How to adjust the microscope parameters of mold laser welding machine?

Mold laser welding machine is a subclassification of laser welding machine, also known as mold laser repair welding machine. Its main principle is to use high-energy laser pulses to perform laser spot welding, laser repair welding and other methods to locally heat the tiny area. ...Nov 20,2024Learn more -

What factors affect laser deep penetration welding?

As one of the two basic modes of laser welding (the other is heat conduction welding), laser deep penetration welding is increasingly widely used. In order to obtain higher laser deep penetration welding benefits, this article summarizes the main influencing factors of this weldi...Nov 20,2024Learn more -

Detailed introduction of mold laser welding machine!

Mold laser welding machine and repair machine repair and weld cracks, broken corners, edges and damaged sealing edges of hard materials such as molds, precision injection molding, die casting, stamping, stainless steel, etc. at a temperature of 50-60 Rockwell; high accuracy, lase...Nov 08,2024Learn more -

What is the advantage of precision laser welding machines?

There are many types of laser welding machines sold on the market, but now many large companies will spend a high price to buy precision laser welding machines. In terms of price, this type of welding machine is very different from ordinary welding machines, but companies will st...Nov 08,2024Learn more

Fiber Laser Welding Machine

-

QCW/Fiber Mobile mold repair laser welding machine

-

QCW/Fiber Mould laser welding machine with crane

-

Handheld fiber laser welding machine

-

Fiber transmission laser welding machine

-

Jewelry welding

-

Handheld galvanometer laser welding machine for Battery Weld Repairs

-

Galvanometer laser mold welding machine

-

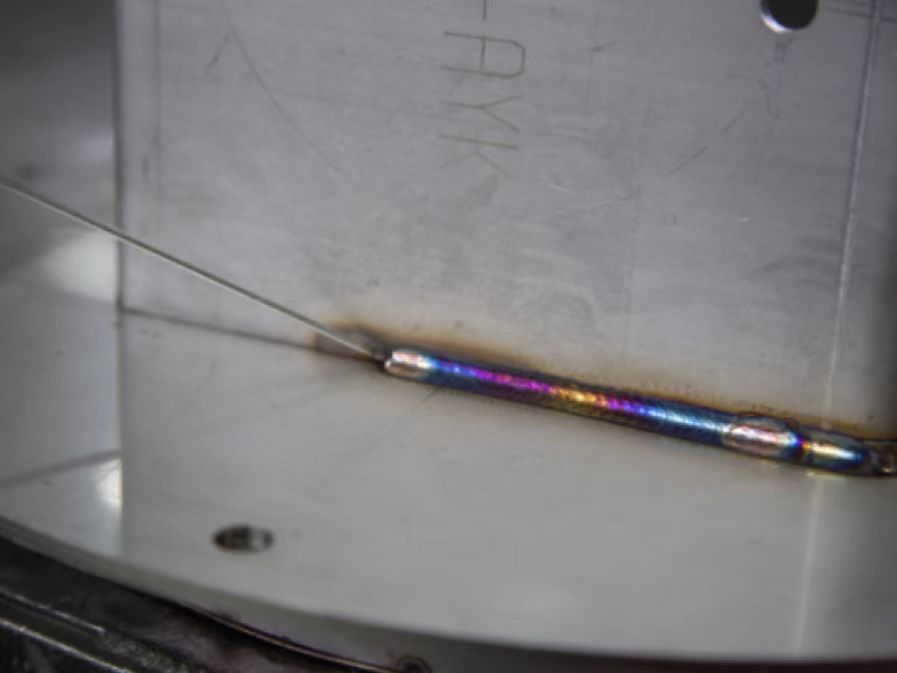

Mold repair fiber laser welding

-

Intergrated boom laser welding machine

-

Automatic laser welding machine

-

Automatic platform laser welding machine

-

Gantry galvanometer laser welding machine

-

Robot welding machine

-

Handheld fiber laser cleaning machine

-

Pulse laser cleaning machine

Welder News

Welder News