- No.609, Centre Of Huijin Nanxiang, Yinxiang Road, Nanxiang Town, Jiading District, Shanghai, China

- sherry@sanmachines.com

- +86-18616767021

What materials can be welded by laser welding machine?

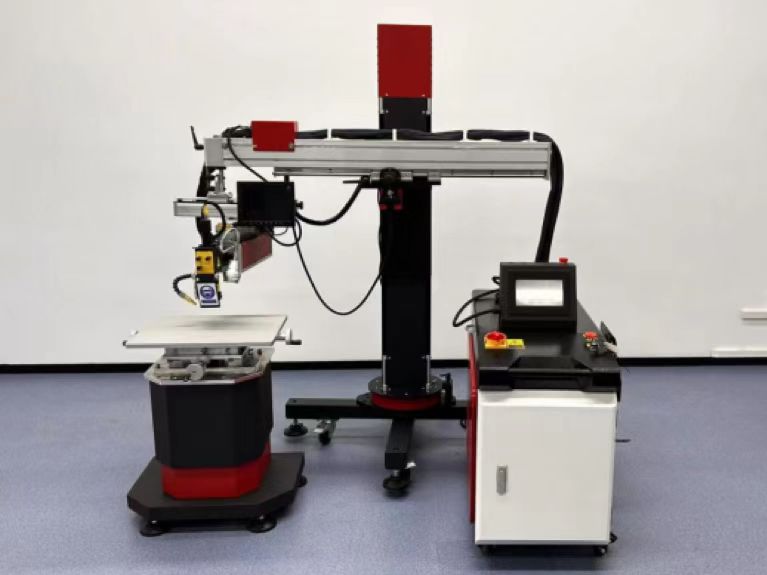

Laser welding machine is a machine used for laser material processing. According to its working mode, it is divided into laser mold welding machine, automatic laser welding machine, laser spot welding machine, and fiber transmission laser welding machine. What materials can be welded by laser welding machine?

1. Carbon steel

Carbon steel is welded by laser welding machine with good effect. The impurity content determines the welding quality. In order to obtain good welding quality, preheating is required when the carbon content exceeds 0.25%. When welding steels with different carbon contents, the welding torch can be slightly offset to the side of the low-carbon material to ensure the quality of the joint. Because the heating and cooling speeds of laser welding machines are very fast, when welding carbon steel. As the carbon content increases, the sensitivity of welding cracks and notches will also increase. Medium and high carbon steels and ordinary alloy steels can all be laser welded well, but preheating and post-weld treatment are required to eliminate stress and avoid cracks.

2. Stainless steel

Generally speaking, it is easier to obtain high-quality joints when welding stainless steel than conventional welding. Due to the high welding speed and small heat-affected zone of laser welding, the overheating phenomenon and the adverse effects of large linear expansion coefficient during stainless steel welding are reduced, and the weld has no defects such as pores and inclusions. Compared with carbon steel, stainless steel is easier to obtain deep-melting narrow welds due to its low thermal conductivity, high energy absorption rate and melting efficiency. Welding thin plates with low-power laser welding can obtain joints with good appearance and smooth and beautiful welds.

3. mold steel

It can be used for laser welding of mold steel models such as S136, SKD-11, NAK80,8407,718,738, H13, P20, W302,2344, etc., with good welding effect.

4. Copper and copper alloys

Copper and copper alloys are prone to welding problems such as lack of fusion and incomplete penetration. A heat source with concentrated energy and high power should be used, and preheating measures should be taken. When the workpiece is thin or the structural rigidity is small and there is no measure to prevent deformation, it is easy to produce large deformation after welding. When the welded joint is constrained by large rigidity, welding stress is easy to occur. Thermal cracks are easy to occur when welding copper and copper alloys. Porosity is a common defect in the welding of copper and copper alloys.

5. Plastics

Almost all thermoplastic plastics and thermoplastic elastomers can use laser welding technology. Commonly used welding materials include PP, PS, PC, ABS, polyamide, PMMA, polyoxymethylene, PET and PBT. Other engineering plastics, such as polyphenylene sulfide (PPS) and liquid crystal polymers, cannot be directly welded with laser technology due to their low laser transmittance. Carbon black is generally added to the base material so that the material can absorb enough energy to meet the requirements of laser transmission welding.

6. Aluminum Alloy

The biggest difficulty in laser welding aluminum sheets and aluminum sheets is that they have a high reflectivity to the Co2 laser beam with a wavelength of 10.8pon. Aluminum is a good conductor of heat and electricity. The high density of free electrons makes it a good reflector of light. The initial surface reflectivity exceeds 90%, that is, deep fusion welding must start at less than 10% of the input energy, which requires a very high input power to ensure the necessary power density at the beginning of welding, and once the pinhole is generated.

7. Magnesium Alloy

The density of magnesium alloy is 36% lower than that of aluminum, and it has attracted much attention as a material with high specific strength. Therefore, pulsed YAG laser and continuous C02 laser welding tests were carried out. For AZ31B-H244 alloy (3.27%Al, 0.79%Zn) with a plate thickness of 1.8MM, the best welding conditions with fewer defects are average power 0.8kW, 5ms, 120Hz, 300mm/s, and focus size 0.42mm. Continuous C02 laser welding obtains a good penetration weld.

8. Low alloy high strength steel

As long as the appropriate welding parameters are selected, laser welding of low alloy high strength steel can obtain joints with mechanical properties equivalent to those of the parent material. HY-130 steel is a typical low alloy high strength steel after quenching and tempering, with high strength and high crack resistance. When welded by conventional welding methods, the weld and HAZ structure are a stick combination of coarse grains and some fine original structures. The toughness and crack resistance of the joint are much worse than those of the parent material, and the weld and HAZ metal structure in the welded state are particularly sensitive to cold cracks.

Related product links

Welder News

Welder News