- No.609, Centre Of Huijin Nanxiang, Yinxiang Road, Nanxiang Town, Jiading District, Shanghai, China

- sherry@sanmachines.com

- +86-18616767021

Working principle and welding characteristics of mold welding machine!

The laser mold welding machine was first called a laser welding machine. During the development process, the mold laser welding machine was also called a mold laser repair machine. However, they all use conventional laser welding methods to achieve local heating of small areas by laser welding machines, laser spot welding, laser repairing, etc., so as to achieve the purpose of melting the material.

Working principle of mold welding machine

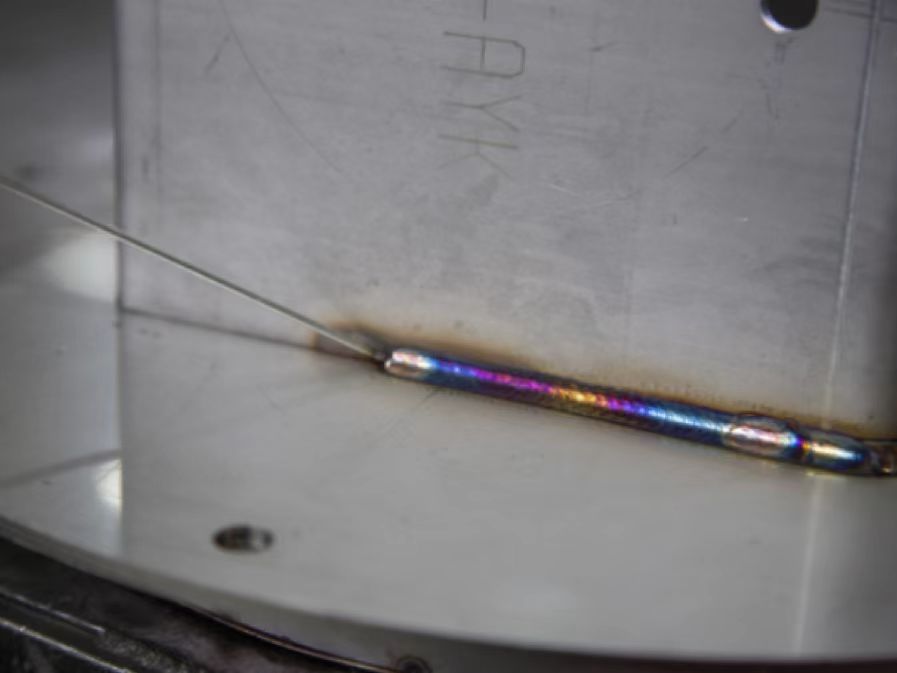

Mold laser welding machine is also a branch of laser welding machine, so the working principle is to use high-energy laser pulses to locally heat the material in a small area. The energy of laser radiation diffuses to the inside of the material through heat conduction, and the material is melted to form a specific molten pool. It is a new type of welding method, mainly for the welding of thin-walled materials and precision parts, and can realize spot welding, butt welding, lap welding, sealing welding, etc. It has a high aspect ratio, a small weld width, a small heat-affected zone, small deformation, fast welding speed, a smooth and beautiful weld, no need for treatment or only simple treatment after welding, high weld quality, no pores, can be precisely controlled, small focusing spot, high positioning accuracy, and easy to realize automation. At present, high-power laser welding machines have been launched, and various styles of laser welding and repair can be achieved for thicker materials.

Features of mold laser welding

The mold laser welding machine uses a large-screen LCD Chinese interface display, which makes it easier for operators to learn and operate. The equipment also uses font programming function to achieve multi-mode work, which is suitable for mold repair of most materials. Not only is the heat-affected area small, the oxidation rate is low, and there will be no sand holes, pores, etc., the effect of repairing the mold is to achieve no bumps at the joint, and it will not cause mold deformation.

Related product links

Welder News

Welder News