-

Advantages of platform laser welding!

Compared with traditional welding methods, the advantages of platform laser welding:1. Fast welding speed: The welding speed of laser welding is faster than that of traditional welding methods. It can save production time and cost.2. High welding quality: The welding quality of l...Jan 07,2025Learn more -

Air-cooled laser welding machine!

Laser welding machine is one of the most widely used equipment in the industrial field. In modern manufacturing, laser welding technology is widely used, and the equipment related to it is also evolving. Air-cooled laser welding machine is one of them, with some unique advantages...Jan 06,2025Learn more -

Classification and characteristics of laser welding machines!

Laser welding machines are often called laser welding machines, energy negative feedback laser welding machines, laser welding machines, laser welding machines, laser cold welding machines, laser argon welding machines, laser welding equipment, etc. Laser welding machines are div...Jan 06,2025Learn more -

Advantages of SAN LASER boom-type mold laser welding machine!

Advantages of SAN LASER boom-type mold laser welding machine1. Different laser pulse waveform settingsFor steel, aluminum, copper and other materials, different waveforms can be selected for laser processing to improve the penetration of laser welding and the controllability of t...Jan 06,2025Learn more -

The difference between fiber mold laser welding machine and common laser welding machine!

Fiber laser mold laser welding machine has more advantages than traditional laser welding machine in terms of transmission medium. These make fiber laser mold welding machine more applicable in certain specific precision welding fields, while traditional laser welding machine sti...Dec 24,2024Learn more -

Functional characteristics of boom type mold laser welding machine

It is specially designed for laser welding of extra-large molds, such as automobile molds, housing molds, tire molds, home appliance plastic shell molds and other large plastic and die-casting molds. The machine is equipped with a crane system that can be raised and lowered, and ...Dec 24,2024Learn more -

How to maintain the QCW laser welding machine?

Because it has the advantages of high efficiency, energy saving, cleanliness and environmental protection, the QCW laser welding machine has become an important equipment in many welding companies. During the use of the equipment, maintenance is an issue that cannot be ignored. O...Dec 23,2024Learn more -

Seven advantages of QCW laser welding machine, six major industry applications!

Compared with traditional lamp-pumped laser welding machines, QCW laser welding machines have the characteristics of good beam quality and small divergence angle. Compared with traditional laser welding machines in high-speed and high-precision welding, the welding efficiency and...Dec 23,2024Learn more -

(CW) continuous laser and (QCW) quasi-continuous laser!

CW, the full name is "Continuous Wave", translated as continuous wave laser, specifically refers to those devices that can provide uninterrupted laser output during operation. The characteristic of this laser is that it can continue to emit laser light until the end of ...Dec 20,2024Learn more -

Advantages and characteristics of mold laser welding machine!

The mold repair laser welding machine uses the high heat energy generated by the laser to weld the special welding wire to the damaged part of the mold, firmly weld it with the original mold substrate, and grind it into a smooth surface after welding, so as to achieve the mold re...Dec 19,2024Learn more

Fiber Laser Welding Machine

-

QCW/Fiber Mobile mold repair laser welding machine

-

QCW/Fiber Mould laser welding machine with crane

-

Handheld fiber laser welding machine

-

Fiber transmission laser welding machine

-

Jewelry welding

-

Handheld galvanometer laser welding machine for Battery Weld Repairs

-

Galvanometer laser mold welding machine

-

Mold repair fiber laser welding

-

Intergrated boom laser welding machine

-

Automatic laser welding machine

-

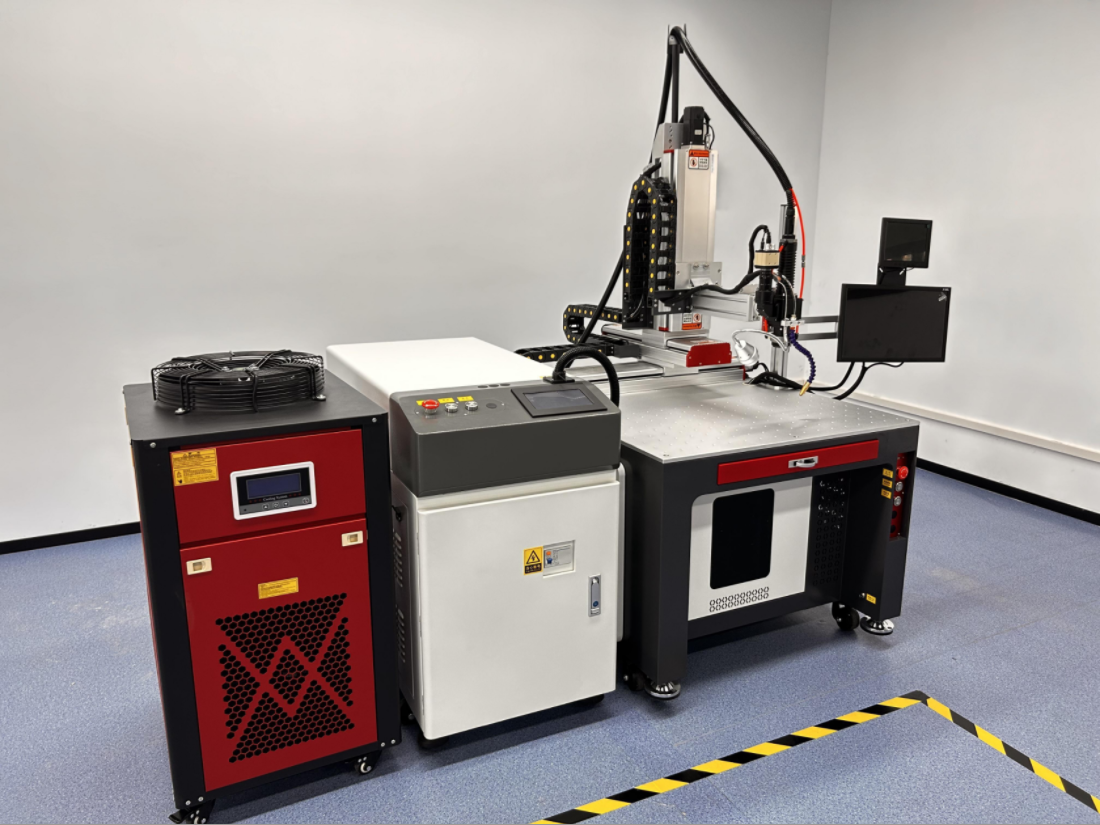

Automatic platform laser welding machine

-

Gantry galvanometer laser welding machine

-

Robot welding machine

-

Handheld fiber laser cleaning machine

-

Pulse laser cleaning machine

Welder News

Welder News