- No.609, Centre Of Huijin Nanxiang, Yinxiang Road, Nanxiang Town, Jiading District, Shanghai, China

- sherry@sanmachines.com

- +86-18616767021

Classification and characteristics of laser welding machines!

Laser welding machines are often called laser welding machines, energy negative feedback laser welding machines, laser welding machines, laser welding machines, laser cold welding machines, laser argon welding machines, laser welding equipment, etc. Laser welding machines are divided into nano-pulse laser welding machines, QCW fiber laser welding machines, and YAG laser welding machines. So what are the differences between these welding machines?

1.Fiber-laser transmission laser welding machine

Fiber-laser transmission laser welding machine is a kind of laser welding equipment that couples high-energy laser beam into optical fiber, transmits it over a long distance, collimates it into parallel light through a collimator, and then focuses it on the workpiece for welding. For parts that are difficult to access for welding, flexible transmission non-contact welding is performed, which has greater flexibility. The laser beam of the fiber-optic transmission laser welding machine can achieve time and energy splitting, and can perform multi-beam processing simultaneously, providing conditions for more precise welding.

2.QCW laser welding machine

The laser of the QCW laser welding machine realizes the rapid movement of the laser point through the oscillation of the galvanometer, so it can realize high-speed and high-precision spot welding and continuous welding of any graphics on the welding plane within the welding range. Therefore, compared with the traditional automatic welding machine that moves the workpiece through the stepper servo motor drive, the welding speed is greatly improved.

QCW laser welding machine is an ideal choice for spot welding, seam welding and long pulse drilling applications. Compact structure design. Due to its electro-optical conversion efficiency of >30% and maintenance-free operation, its cost-effectiveness is far better than that of conventional YAG lasers. Mainly for the welding of thin-walled materials and precision parts, it can realize spot welding, butt welding, lap welding and sealing welding.

3.YAG laser welding machine

YAG laser welding machine is mainly used for welding thin-walled materials and precision parts. It can realize spot welding, butt welding, lap welding and sealing welding. It has high depth ratio, small weld width, small heat-affected zone, small deformation and fast welding speed. The weld is flat and beautiful, and no post-welding treatment is required or only simple treatment procedures are required.

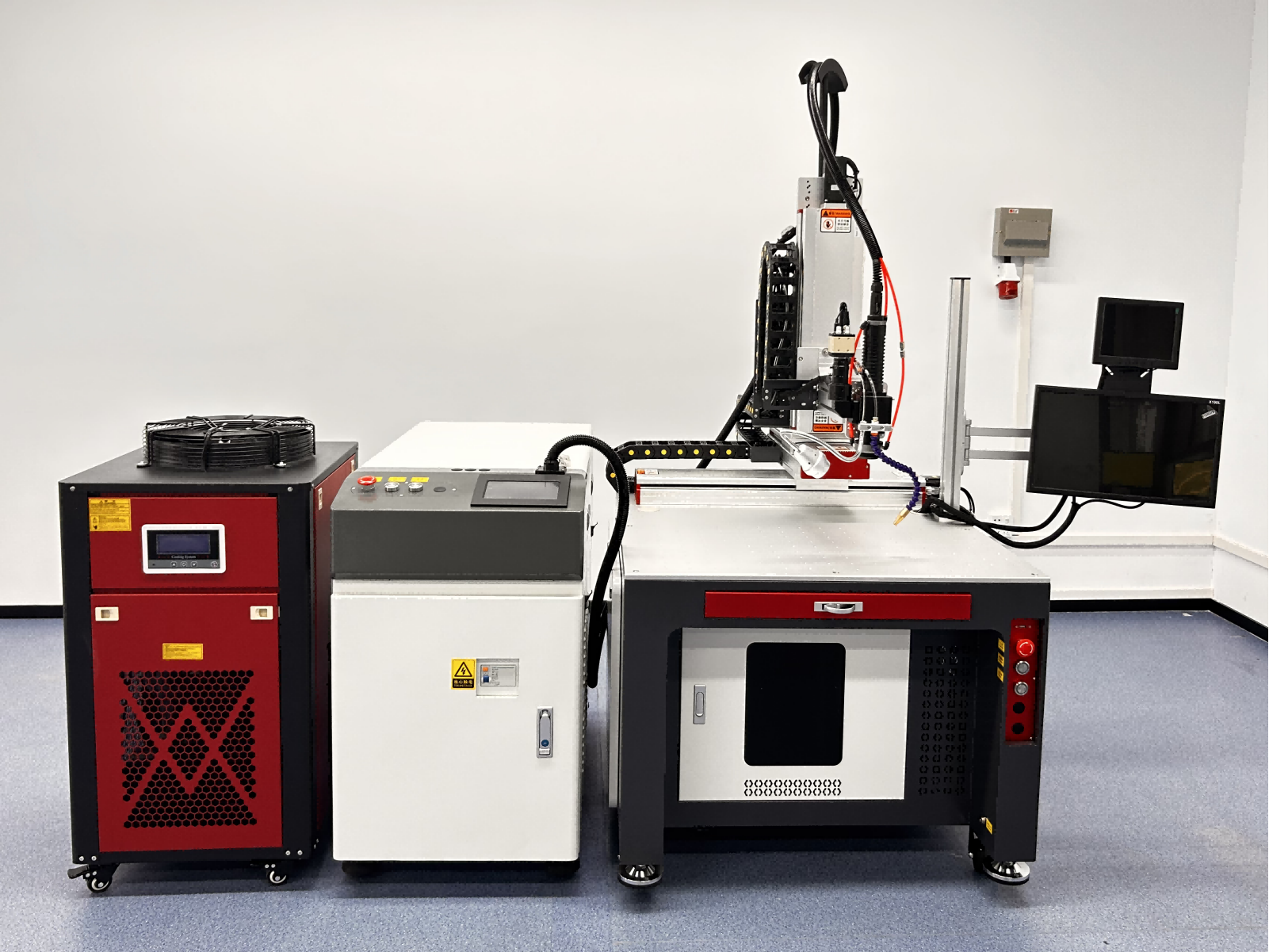

SAN LASER is a professional manufacturer of laser welding equipment. It can customize different types of laser welding equipment according to customers' welding requirements, and can add CCD positioning system and visual inspection system according to customers' welding needs to meet customers' fully automatic welding needs.

Related product links

Welder News

Welder News