- No.609, Centre Of Huijin Nanxiang, Yinxiang Road, Nanxiang Town, Jiading District, Shanghai, China

- sherry@sanmachines.com

- +86-18616767021

(CW) continuous laser and (QCW) quasi-continuous laser!

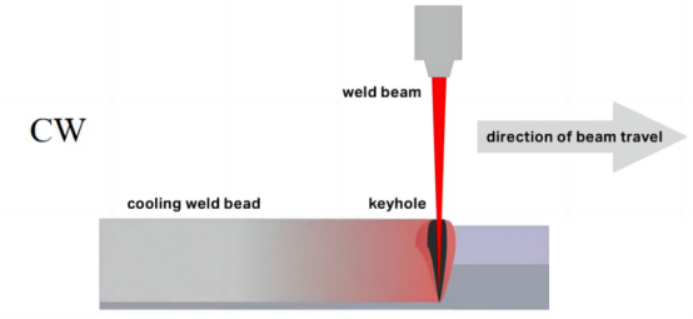

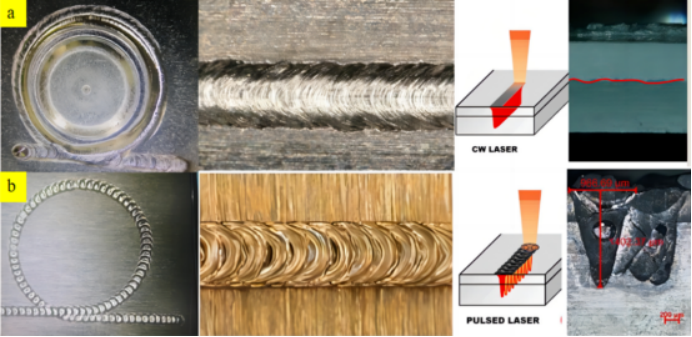

CW, the full name is "Continuous Wave", translated as continuous wave laser, specifically refers to those devices that can provide uninterrupted laser output during operation. The characteristic of this laser is that it can continue to emit laser light until the end of the operation. CW lasers are known for their lower peak power and higher average power compared to other laser types. Due to its continuous output characteristics, it is widely used in metal cutting, copper and aluminum welding and other fields, becoming one of the most common and widely used types of laser. Its ability to provide continuous and stable energy output makes it particularly important in both precision machining and mass production. When debugging the continuous laser process, we mainly focus on several key parameters, including power waveform, defocus amount, spot core diameter and processing speed. Precise adjustment of these parameters is crucial to achieve optimal processing results and ensure high efficiency and high quality of the laser processing process.

Continuous laser energy distribution characteristics

A distinctive feature of continuous (CW) lasers is the Gaussian pattern of their energy distribution, that is, the energy distribution of the laser beam cross-section shows a Gaussian (normal distribution) shape that is highest in the center and gradually decreases outward. This distribution characteristic enables CW lasers to achieve extremely high focusing accuracy and processing effects when performing precision machining, especially in application scenarios that require highly concentrated energy.

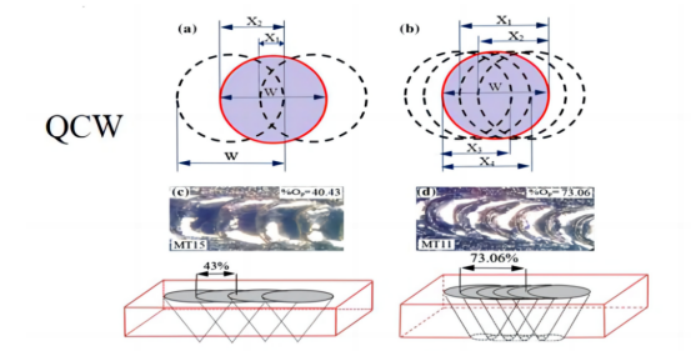

QCW, or "quasi-continuous wave" laser,

works by emitting laser light intermittently, which is different from the uniform energy distribution of single-mode continuous wave lasers. The energy distribution of QCW lasers is more concentrated, which means they have higher energy density and thus achieve stronger penetration capabilities. In metallurgy, this energy distribution can form a "nail"-shaped molten pool with a large depth-to-width ratio, giving QCW laser significant advantages in processing highly reflective alloys, heat-sensitive materials, and micro-joints.

A significant advantage of QCW laser welding is that it can avoid the impact of metal plume on the material's absorbance, making the welding process more stable. During the interaction between laser and material, intense evaporation will form a mixed gas of metal vapor and plasma above the molten pool, that is, metal plume. These plumes may block the laser from reaching the surface of the material, causing the laser power to be unstable, thereby generating Defects such as splashes, blasted spots, and pits. The intermittent light emission method of QCW (for example, 5ms light emission, 10ms intermittent) ensures that each time the laser irradiates the material surface, it will not be affected by the metal plume, and the welding process is relatively more stable, especially suitable for the welding of thin plate materials.

compared to:

Under the same average power, QCW laser can achieve higher peak power and higher energy density, thereby achieving greater penetration depth and stronger penetration. This is especially advantageous in the welding of copper alloy and aluminum alloy sheets. Continuous lasers with the same average power may not be able to form welding spots on the material surface due to their low energy density. However, continuous lasers with too high power will have a sharp increase in absorption rate after melting the material, and the heat input will suddenly increase, resulting in penetration depth and heat loss. Uncontrolled input cannot be used in thin plate welding, which may result in failure to form a weld or penetrate the material, failing to meet process requirements.

Related product links

Welder News

Welder News