-

Can fiber laser welding machine repair molds?

Molds play an extremely important role in modern industry, and their quality directly determines the quality of products. However, during the use of molds, problems such as collapse, deformation, wear, and even breakage often occur. In order not to delay production, molds need to...Dec 19,2024Learn more -

QCW laser welding machine!

Product description: QCW laser welding machine is ideal for spot welding, seam welding and long pulse drilling applications. Compact structure design. Due to its electro-optical conversion efficiency of >30% and maintenance-free operation, its cost-effectiveness is far superior t...Dec 19,2024Learn more -

Application scope of laser cleaning machine!

The application range of laser cleaning machines is very wide, covering multiple industries and fields.The following are some of the main application ranges: Mold cleaning: Grease, dirt, rust and other pollutants on the mold surface can be effectively removed by laser, ...Dec 17,2024Learn more -

How should the pulse width of a laser welding machine be selected?

During the welding process of a laser welding machine, the selection of pulse width (pulse width for short) is one of the important parameters that affect the quality and efficiency of welding. The correct pulse width setting can not only improve the accuracy and consistency of w...Dec 10,2024Learn more -

Principle of laser beam welding!

Proponents of laser beam welding (LBW) and electron beam welding (EBW) both praise their favorite technologies, but for customers, the best solution is often to use both technologies at the same time. Both processes are well suited to joining parts with complex geometries and are...Dec 10,2024Learn more -

Laser welding machine trends!

1. For upper-level laser equipment, laser crystals are still used as an example. Development trends include advanced high-power, high-energy laser crystal manufacturing technology, laser weapons, etc.; for human eye safety, remote sensing, optical communications, medical treatmen...Dec 10,2024Learn more -

Difference between fiber laser welding machine and YAG laser welding machine!

Features of fiber laser welding machine: 1. It belongs to continuous welding. 2. No maintenance required, low consumables cost (only protective mirror and brass nozzle) 3. More suitable for welding raw materials with a thickness of more than 2mm. 4. While main...Dec 09,2024Learn more -

Laser welding machine: single wire feeding vs double wire feeding!

Laser welding technology has become a cornerstone of modern manufacturing, offering unparalleled precision, speed, and versatility. A key aspect of its operation lies in the wire feeding mechanism, which introduces filler material into the welding process to effectively join or r...Dec 04,2024Learn more -

A report to understand automatic laser welding machine!

Fully automatic laser welding machines are increasingly widely used in the market. Compared with traditional welding methods, automatic laser welding machines can weld fixed points at a long distance, and their CCD visual positioning device and automatic distance measuring device...Dec 04,2024Learn more -

How to achieve seamless welding with fiber laser welding equipment?

Fiber laser welding machine is a machine used for laser material processing, also often called laser welding machine, laser welding machine. According to its working mode, it can be divided into laser mold welding machine, automatic fiber laser welding machine, laser spot welding...Dec 03,2024Learn more

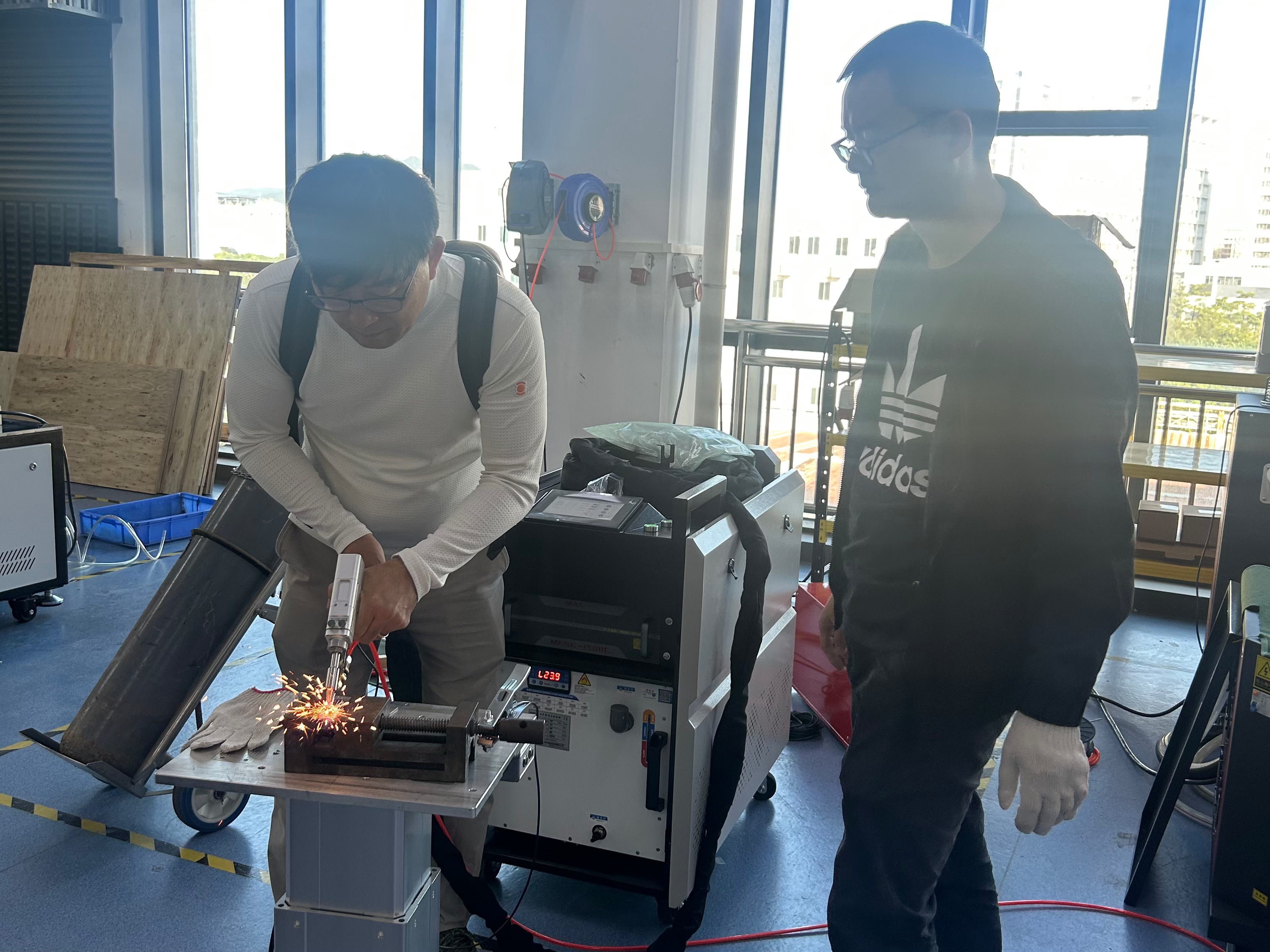

Fiber Laser Welding Machine

-

QCW/Fiber Mobile mold repair laser welding machine

-

QCW/Fiber Mould laser welding machine with crane

-

Handheld fiber laser welding machine

-

Fiber transmission laser welding machine

-

Jewelry welding

-

Handheld galvanometer laser welding machine for Battery Weld Repairs

-

Galvanometer laser mold welding machine

-

Mold repair fiber laser welding

-

Intergrated boom laser welding machine

-

Automatic laser welding machine

-

Automatic platform laser welding machine

-

Gantry galvanometer laser welding machine

-

Robot welding machine

-

Handheld fiber laser cleaning machine

-

Pulse laser cleaning machine

Welder News

Welder News