- No.609, Centre Of Huijin Nanxiang, Yinxiang Road, Nanxiang Town, Jiading District, Shanghai, China

- sherry@sanmachines.com

- +86-18616767021

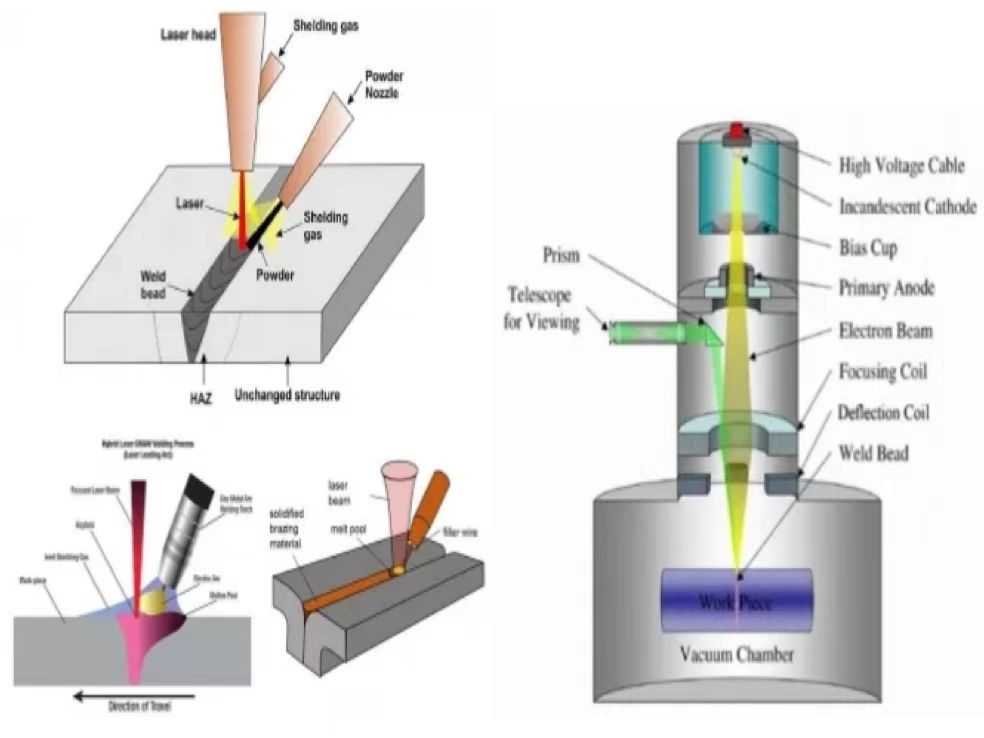

Principle of laser beam welding!

Proponents of laser beam welding (LBW) and electron beam welding (EBW) both praise their favorite technologies, but for customers, the best solution is often to use both technologies at the same time. Both processes are well suited to joining parts with complex geometries and are able to meet the most stringent requirements for the metallurgical properties of the final component.

Laser beam welding (LBW)

Laser welding energy utilizes continuous wave (CW) or pulsed output of photons. For continuous wave systems, the laser beam is always on during the welding process. Pulse systems are modulated to output a series of pulses with off time between these pulses. Both methods focus the laser beam optically on the surface of the workpiece to be welded. These laser beams can be delivered directly to the part through classic hard optics, or through highly flexible fiber optic cables that can deliver laser energy to remote workstations.

The high energy density of the laser causes the surface of the material to quickly reach its liquid temperature, which can shorten the beam interaction time compared to traditional welding methods such as GTAW (TIG welding) and similar processes. As a result, less energy is allocated to the interior of the workpiece. This results in a narrow heat-affected zone and reduced fatigue losses.

Electron Beam Welding (EBW)

EBW is widely accepted in many industries and can weld refractory and dissimilar metals that are not usually suitable for other methods. The kinetic energy of the electrons is converted into heat, which in turn is the driving force for fusion. Usually, no added filler material is required or used, and post-weld distortion is minimal. The ultra-high energy density allows deep penetration and high aspect ratios, while the vacuum environment ensures atmospheric contamination-free welds, which are essential for electron beam welding of materials such as titanium, niobium, refractory metals and nickel-based superalloys.

However, the main requisite for operating under vacuum is precise control of the electron beam. Electrons scatter when they interact with air molecules. By reducing the ambient pressure, the electrons can be more tightly controlled. Modern vacuum chambers are equipped with state-of-the-art seals, vacuum sensors and high-performance pumping systems for rapid evacuation. These features make it possible to focus the electron beam to a diameter of 0.3 to 0.8 mm. By incorporating the latest microprocessor computer numerical control (CNC) and system monitoring capabilities for superior part manipulation, a wide range of part sizes and qualities can be joined without over-melting smaller parts. Precise control of the electron beam diameter and travel speed enables the fusion of materials from 0.001" to several inches thick. These features make EBW an extremely valuable technology.

Related product links

Welder News

Welder News