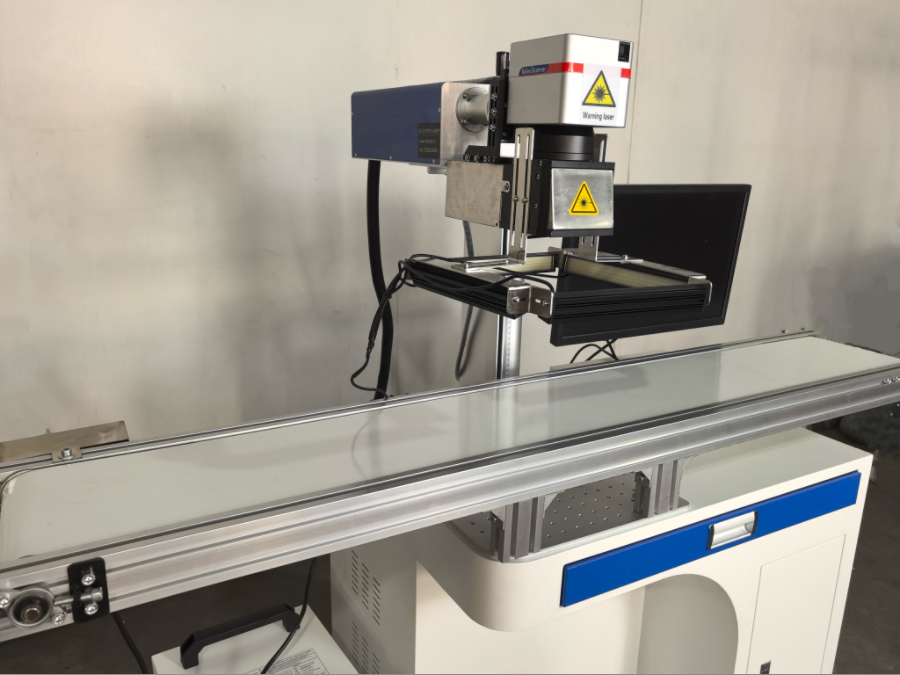

Visual positioning laser marking machine

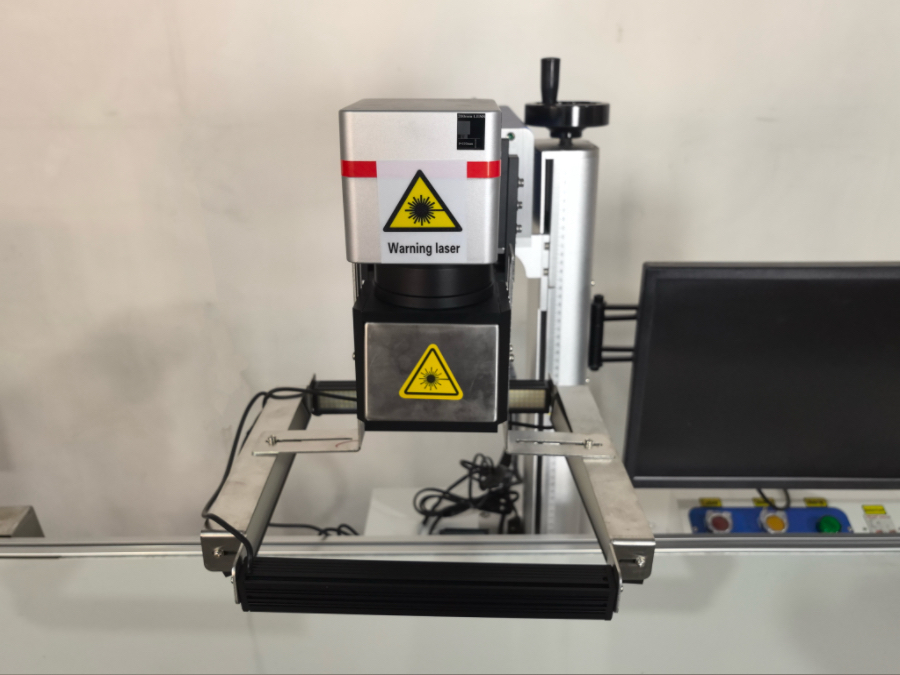

Get a free quote1.On the basis of traditional marking machines, a high-pixel CCD camera is used to locate the current position of the product, and the position information of one or more products is collected in real time and transmitted to the marking control card through a computer to achieve accurate marking.

2.The visual positioning marking system realizes fast positioning, marks multiple products at one time, and can also be used for automatic assembly line feeding. After positioning, visual positioning marking is performed, which saves labor, improves work efficiency, and is easy to realize an automated production line compatible with multiple products, saving labor costs.

3.Compared with traditional laser marking machines, the marking interval is faster, saving 3-5 times the time of moving products, and the position accuracy is higher. With its unique positioning system, the CCD laser marking machine is particularly suitable for the ultra-fine processing market, handicrafts, IC electronic parts, PCB circuit boards and other polymer material surface marking.

4.The CCD visual positioning laser marking machine uses a visual positioning system to establish a standard template for the product before processing.Then, during batch processing, the system will automatically take pictures of the product and feed it at will to achieve accurate positioning and perfect marking, which greatly improves the marking efficiency.

Video

Technical Parameter

| Laser power | 30w | 50w | 100w |

| Laser Wavelength | 1064nm | ||

| Laser Source | jpt/raycus/keruisi | ||

| Single Pulse Energy | 0.75mj | 1.0mj | 2.0mj |

| Frequency Range | 40-60KHz | 1-4000KHZ | 1-4000KHZ |

| Visual Positioning Range | 70X70mm,110X110mm(Standard) | ||

| Software | SAN-CCD visual posioning software | ||

| Accuracy | 士0.02mm | ||

| Operating Environment | 0°C~40°C(Non-condensing) | ||

Application

Applied in various industries: computer accessories, watch calipers, circuit chips, wires and pipes, industrial bearings, auto parts, digital appliances, hardware parts, wood and leather, paper packaging, jewelry, acrylic, etc.

Production Facility

Visual positioning laser marking machine

Visual positioning laser marking machine