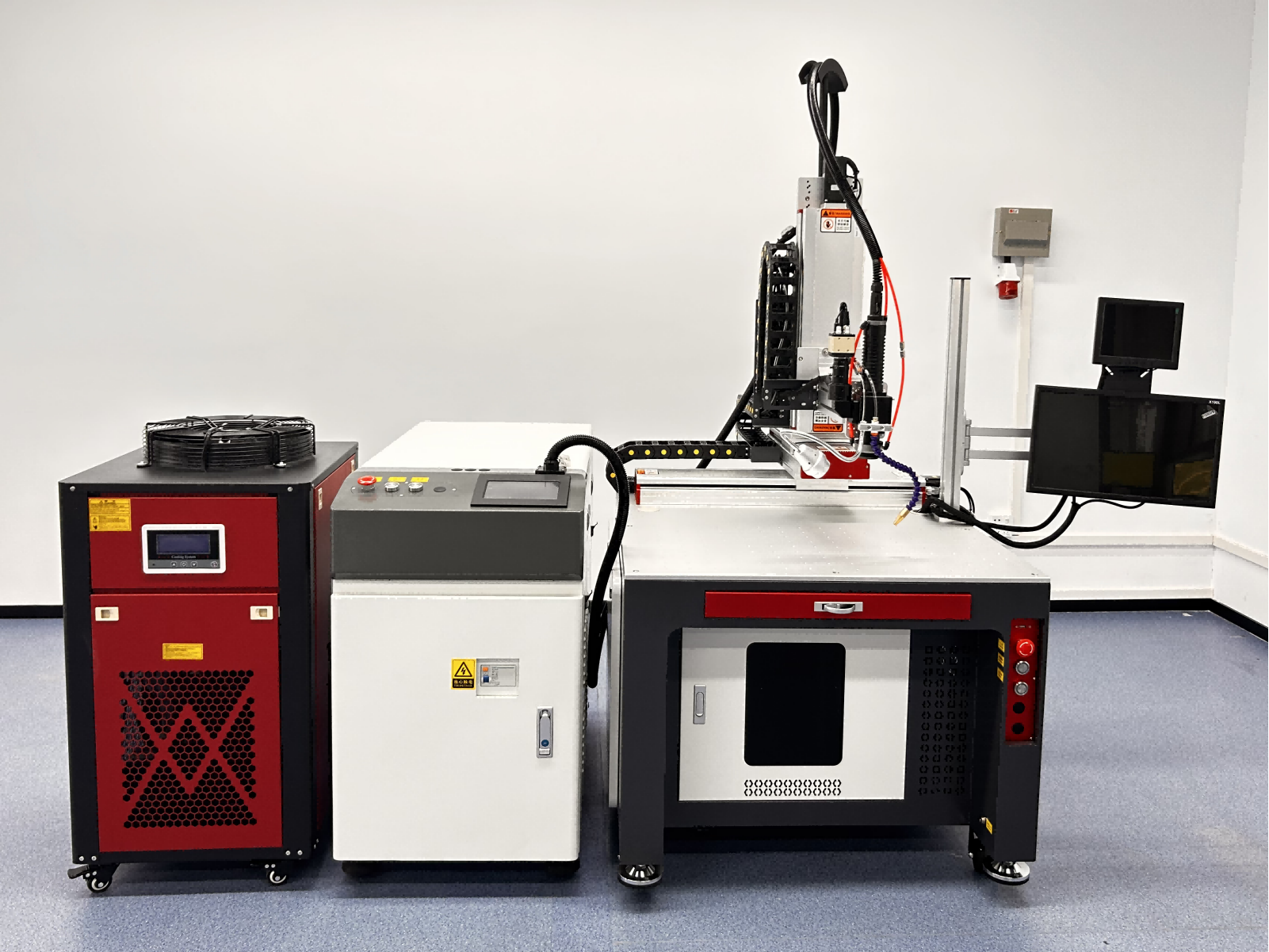

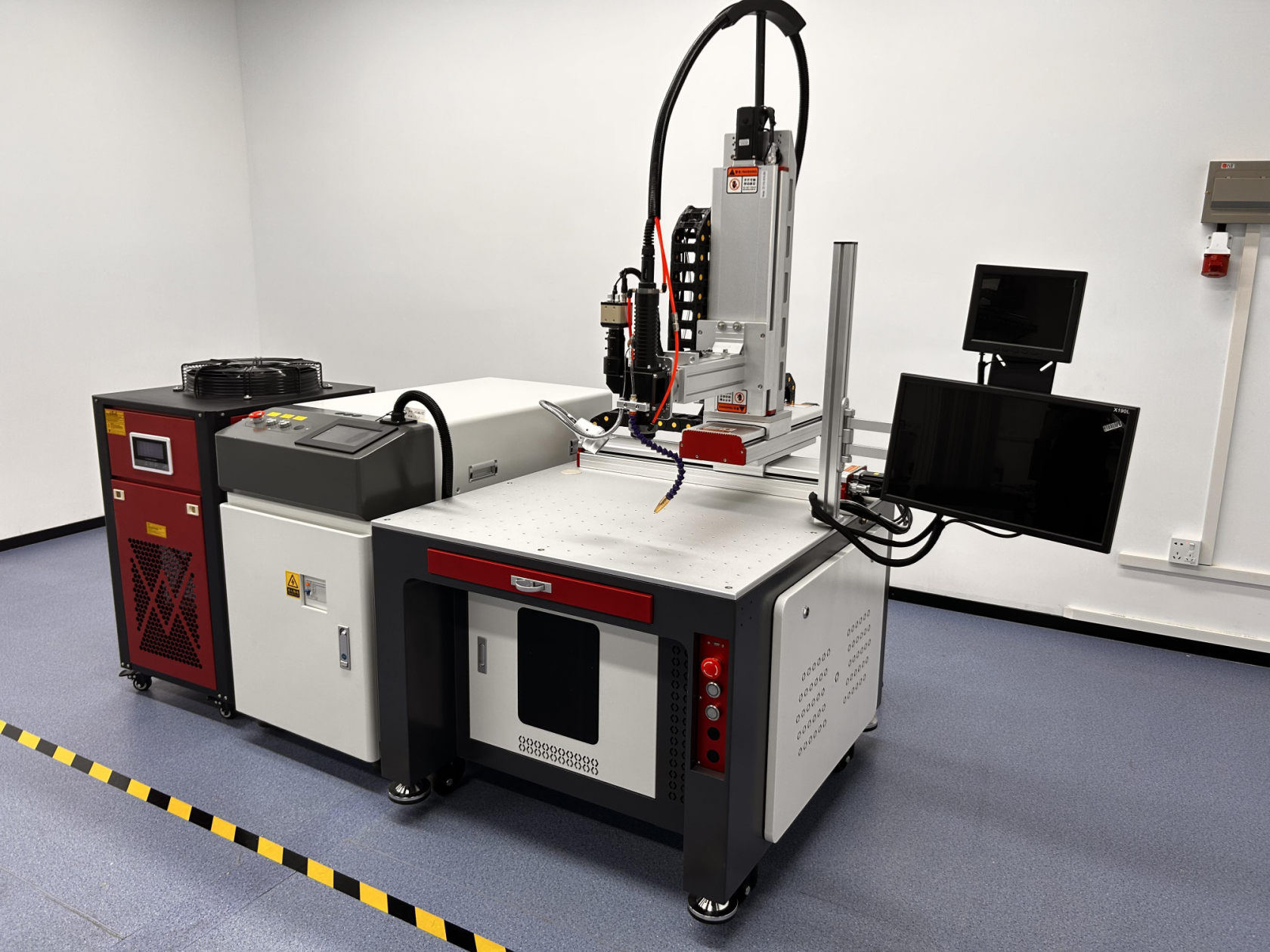

Fiber transmission laser welding machine

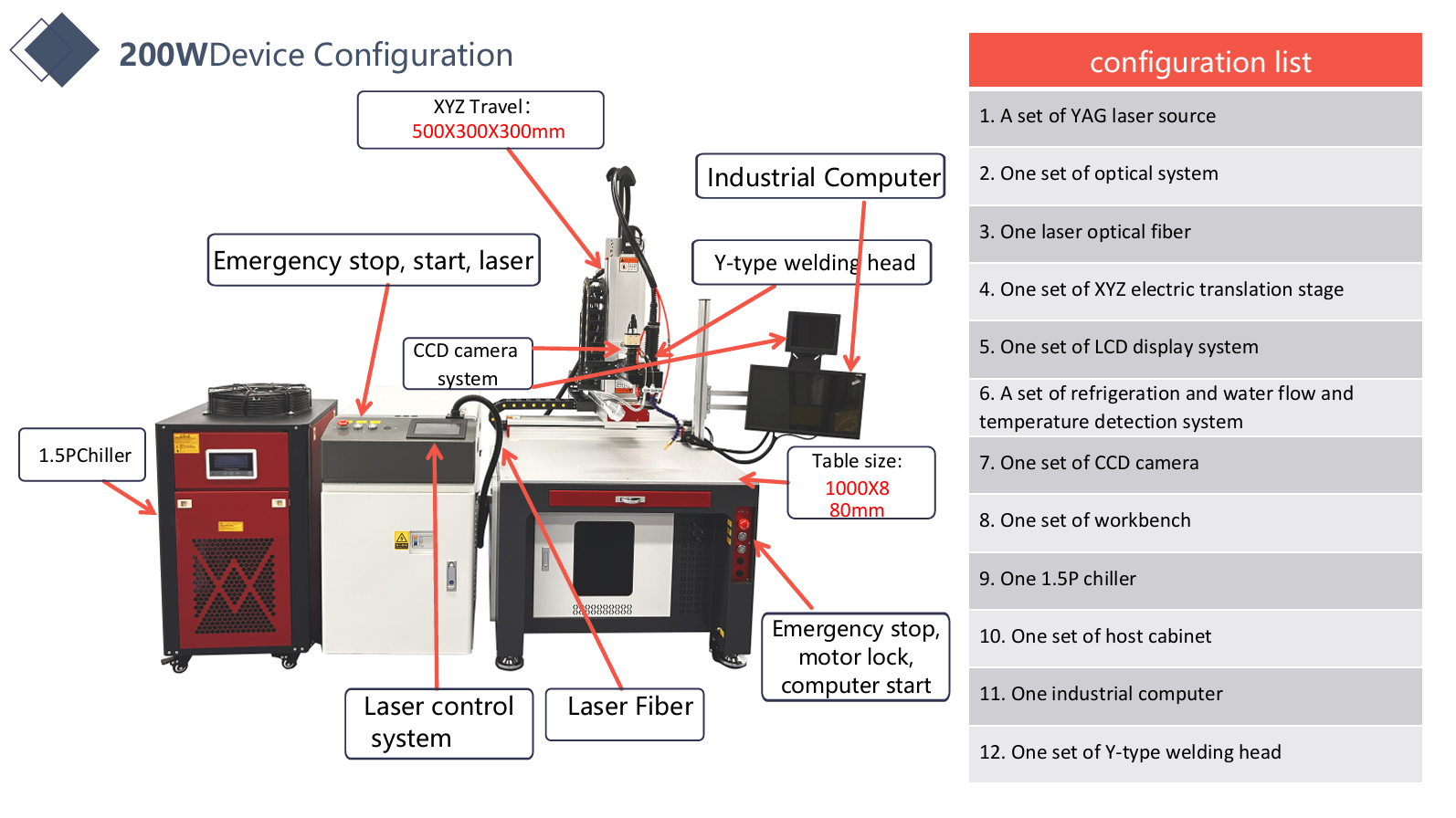

Get a free quote1. It uses imported gold-plated focusing cavity, which has high reflectivity, strong energy, high temperature resistance, corrosion resistance, and ultra long service life. It can obtain good beam quality and more uniform welding;

2. It is equipped with a 1.5 special chiller, which can meet the requirements of long-term and high-power welding with better stability;

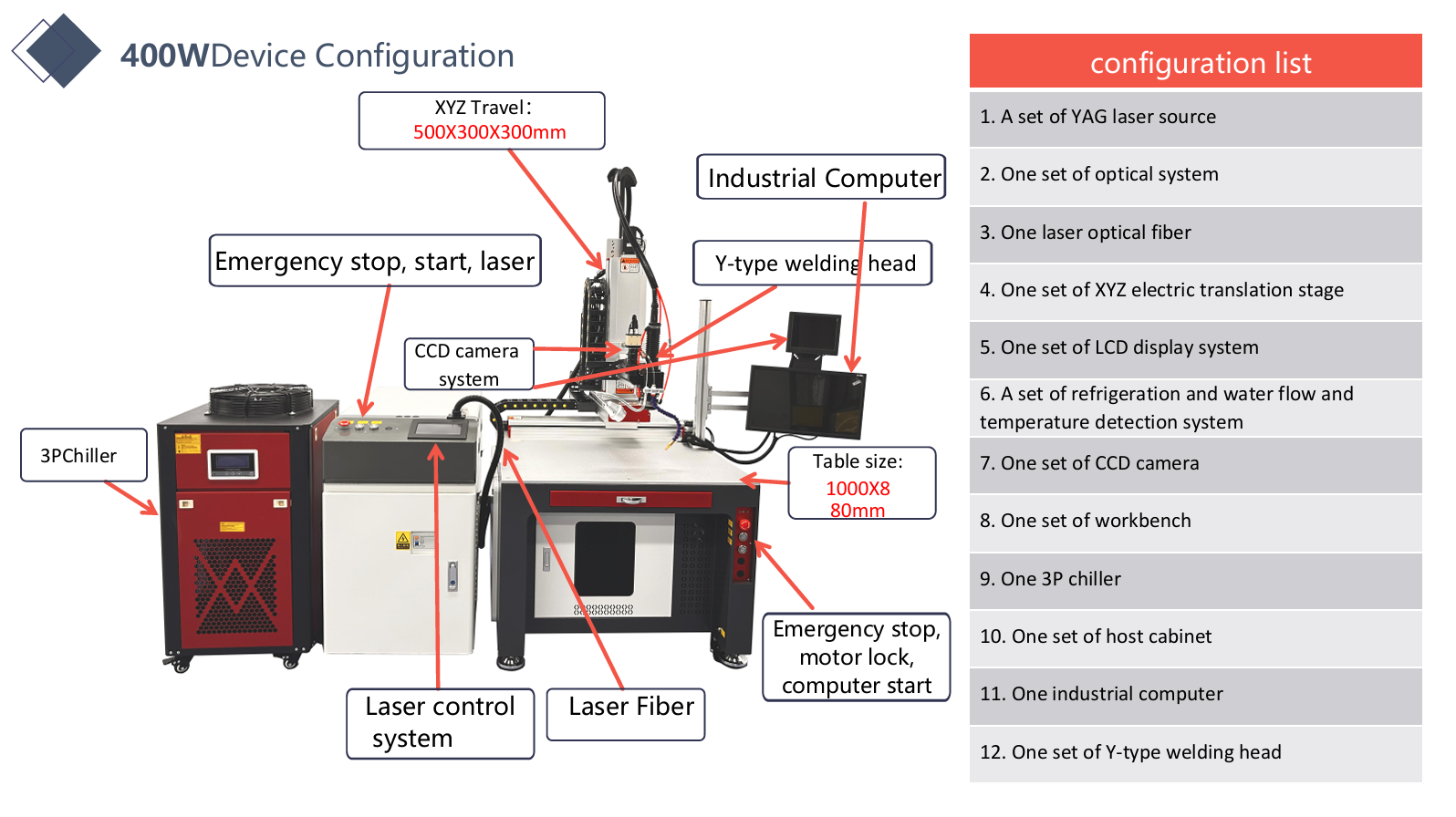

Note: 400W with 3P chiller, 600W with 5P chiller

3. Specialized welding control system, high stability, easy to

understand and learn, can realize continuous spot welding, straight line, circle, arc, etc. and can be programmed arbitrarily;

4. Unique optical system design, stable optical performance;

5. Adopt electric translation stage, high repetitive positioning accuracy, fast welding speed and fast processing speed.

Video

Technical Parameter

| Modle | 200W | 400W | 600W |

| Laser wavelength | 1064nm | ||

| Focusing cavity reflector | Ceramic focusing cavity | Dual lamp spotlight cavity | Dual lamp spotlight cavity |

| Laser frequency | 1-20Hz | 1-30Hz | 1-30Hz |

| Current adjustment range | 60-150A | ||

| Pulse width | 0.1-10Ms | 0.1-10Ms | 0.1-10Ms |

| Light spot adjustment range | 0.2-2m | 0.3-3mm | 0.3-3.5mm |

| Chiller cooling power | 1.5P | 3P | 5P |

| Aiming and positioning | CCD or red light | ||

| Rated power | 8KW | 12KW | 16KW |

| Electricity demand | 380V±5V 50Hz/40A 220V±5V 50Hz/60A | 380V±5V 50Hz/40A | 380V±5V 50Hz/40A |

| Workbench parameters | |||

| XYZ Travel | 500×300×300mm | ||

| Position accuracy | 0.05mm | ||

| Repeatability | 0.05mm | ||

| Maximum movement speed | 150mm/s | ||

| Optional components | Servo/stepper motor, automatic wire feeding, rotating axis, machine head swing, extended stroke | ||

Application

It is suitable for welding of titanium, nickel, tin, zinc, copper, aluminum, chromium, gold, silver and other metals and their alloys, steel, kovar and other alloys between the same materials, and can also be used for welding of copper-nickel, nickel-titanium, copper titanium, brass-copper, low carbon steel-copper and other dissimilar metals

Production Facility

Fiber transmission laser welding machine

Fiber transmission laser welding machine