- No.609, Centre Of Huijin Nanxiang, Yinxiang Road, Nanxiang Town, Jiading District, Shanghai, China

- sherry@sanmachines.com

- +86-18616767021

How Laser Power Affects Welding: Explained!

What determines the quality and efficiency of a weld? In laser welding, the power setting is crucial. This article dives into how laser power impacts welding outcomes, from penetration depth to welding speed. Readers will learn the principles behind laser welding, the relationship between power and weld quality, and practical tips for optimizing welding processes. Get ready to understand the science that shapes perfect welds and improve your welding skills.

1.Principle of double beam welding

Classification of laser welding

1) According to power density and weld formation characteristics:

Heat conduction welding: power density (laser output power/focal spot area)<105W/cm2

Deep penetration welding: power density > 106W/cm2

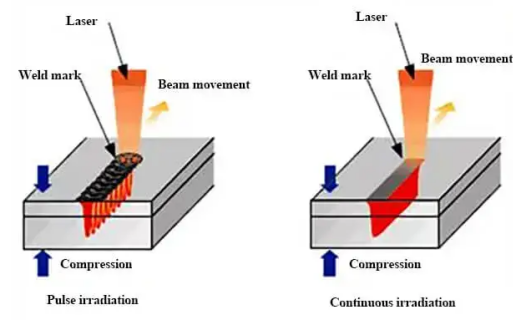

2) According to the laser output mode:

Pulse laser welding

Continuous laser welding

Fig. 1 Schematic diagram of pulsed laser welding and continuous laser welding

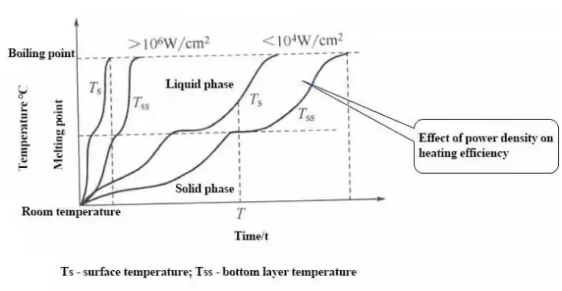

2. Selection of laser power P

The choice of P (laser power) is based on the thickness of the plate. P determines the power density of the spot and influences both the penetration depth and the welding speed.

Fig.2 Curve of power density and metal temperature with time

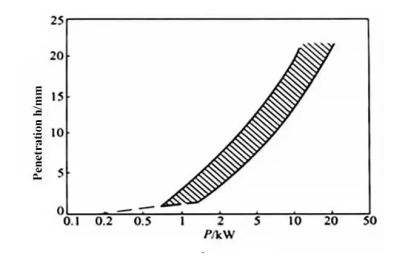

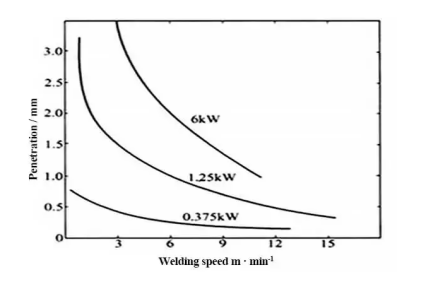

3. Effect of laser power on penetration

As illustrated in the figure, the greater the power (P/kw), the deeper the penetration, and vice versa.

Fig. 3 Relationship between laser penetration and power

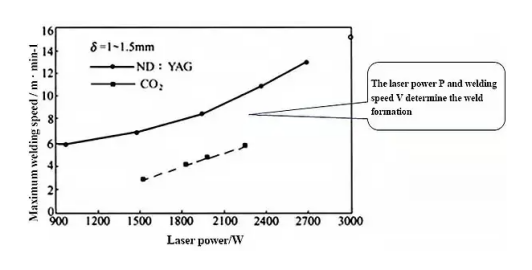

4. Influence of laser power on welding speed

Supplementary knowledge points:

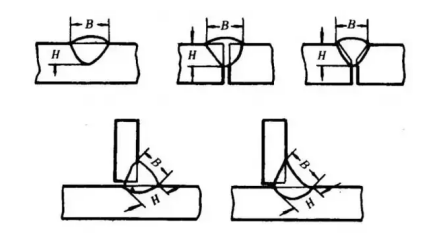

The form factor of a weld is defined in GB/T3375-1994 as the ratio of the weld width (B) to the calculated weld thickness (H) on the cross-section of a single weld (φ = B/H), as shown in Figure 4.

A small form factor results in a narrow and deep weld. However, the center of the weld tends to have higher concentrations of impurities and poor thermal crack resistance due to regional segregation. Therefore, the form factor should not be too small.

For example, the form factor of the weld should be greater than 1.3, meaning the width of the weld should be at least 1.3 times the calculated thickness of the weld.

Fig. 4 Laser power and speed determine the forming of weld

Fig. 5 Relationship between welding speed and laser power

5. Relationship between laser power, welding speed and penetration

Fig. 6 Changes of penetration and welding speed of low carbon steel under different power

Summary:

The laser welding power determines the power density of the spot and controls the penetration depth and speed of welding. As the laser power increases, both the welding speed and penetration depth increase.

Related product links

Welder News

Welder News