Mold repair laser welding machine(YAG)

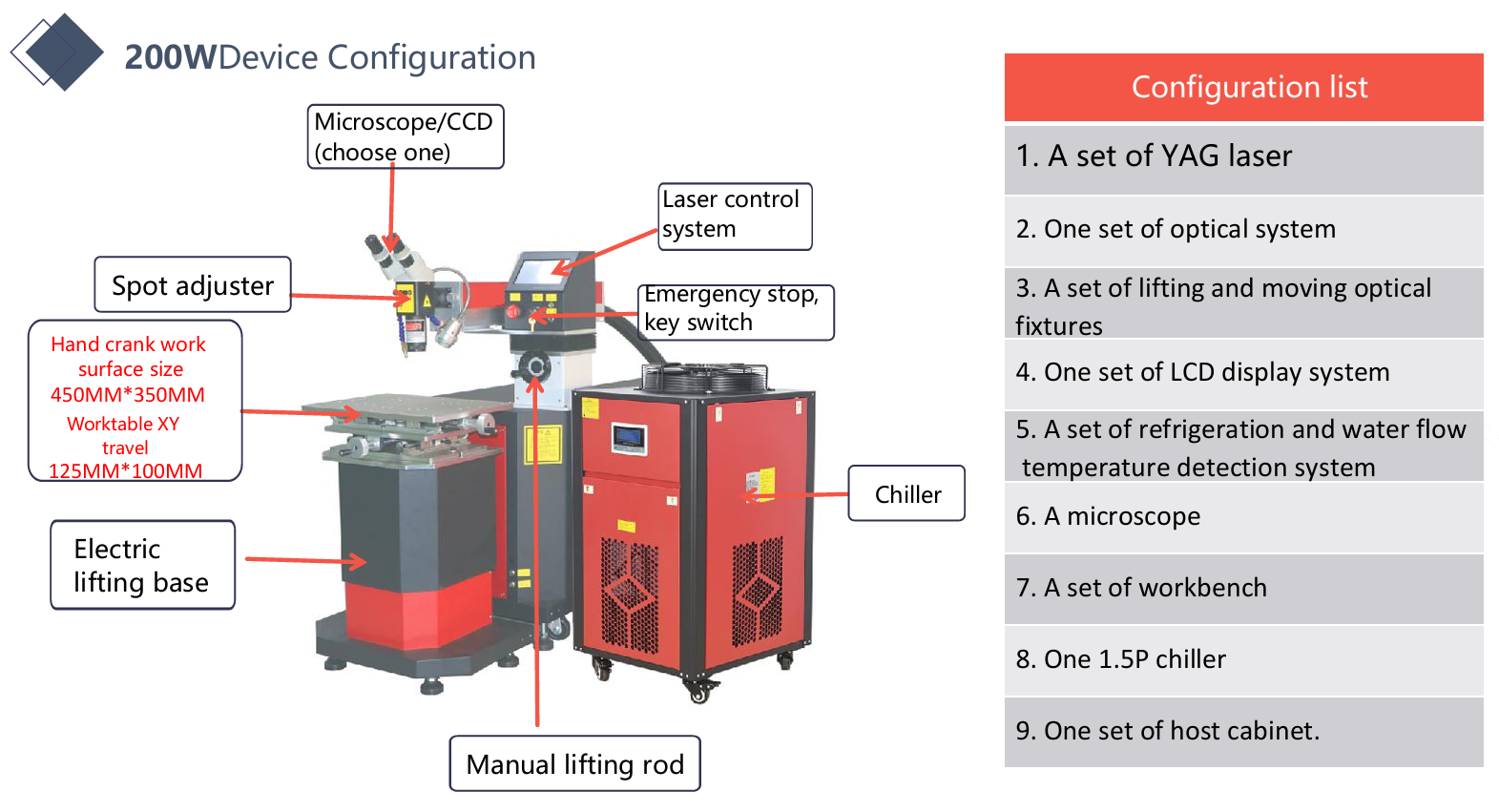

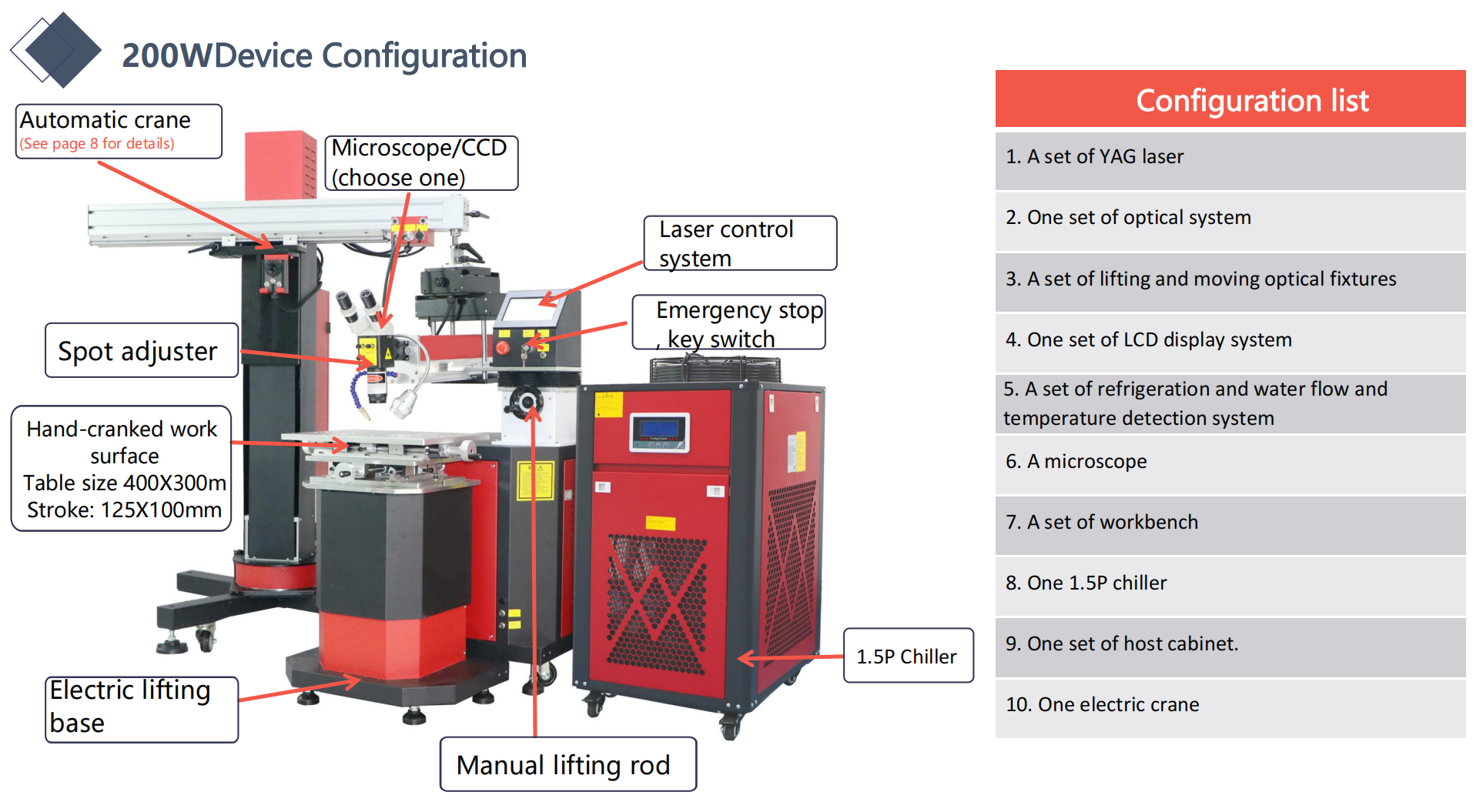

Get a free quote1. Adopt imported ceramic focusing cavity, with high reflectivity, strong energy, high temperature resistance, corrosion resistance and ultra-long service life;

2. Equipped with 1.5 special chiller, it can meet the requirements of long-term and high-power welding with better stability;Note: 400W with 3P chiller

3. Equipped with three-dimensional load-bearing table base electric lifting, the table moves using precision ball screws and high-precision straight rails, which are light and flexible, with precise positioning and a load-bearing capacity of 100 kg;

4. The laser head can slide back and forth, lift manually, and the laser head can be easily rotated 180 degrees, which is convenient for welding any side;

5. Equipped with a gas protection system, which effectively protects the product from argon protection during the welding process, maintains the original color of the product and ensures the welding quality.

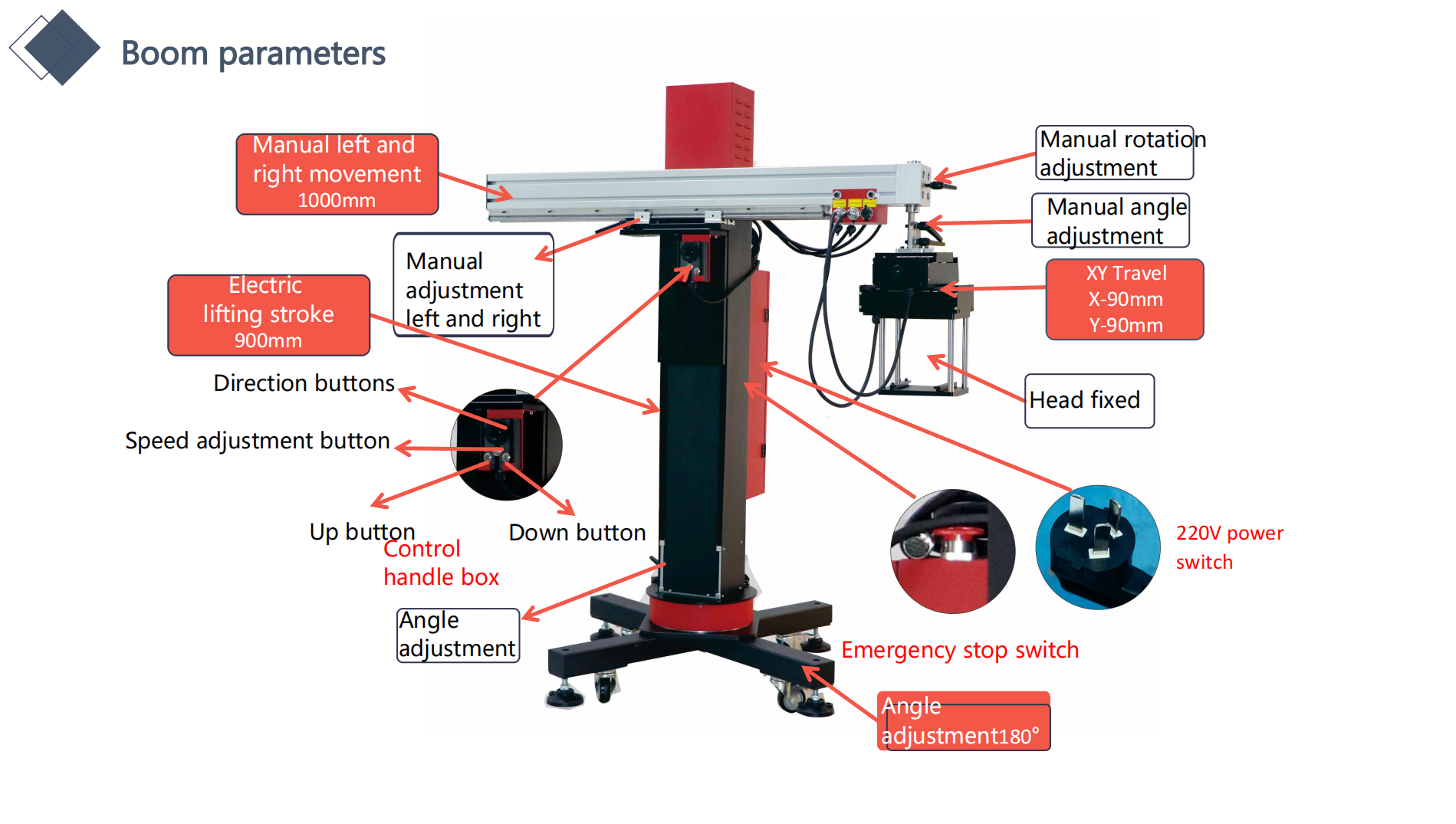

With Boom :

Video

Technical Parameter

| Model | SAN-200W | SAN-400W |

| Laser wavelength | 1064nm | 1064nm |

| Focusing cavity reflector | Imported ceramic focusing cavity | Imported ceramic focusing cavity |

| Current adjustment range | 60-150A | 60-150A |

| Laser frequency | 1-20Hz | 1-30Hz |

| Pulse Width | 0.1-10ms | 0.1-10ms |

| Light spot adjustment range | 0.2-2mm | 0.2-3mm |

| Aiming and positioning | Microscope (optional camera system) | Microscope (optional camera system) |

| Chiller cooling power | 1.5P | 3P |

| Rated power | 8KW | 12KW |

| electricity demand | 380V±5V 50Hz/40A 220V±5V 50Hz/60A | 380V±5V 50Hz/40A |

| Overall dimensions/net weight | Host:1450×550× 1140mm | Host:1450×550× 1140mm |

| Chiller:600×500×970mm | Chiller:640×580×1100mm |

Application

It is suitable for repairing cracks, chipping corners, touching edges and damaged sealing edges of hard materials such as molds, precision injection molding, die casting, stamping, stainless steel, etc.

Production Facility

Mold repair fiber laser welding

Mold repair fiber laser welding