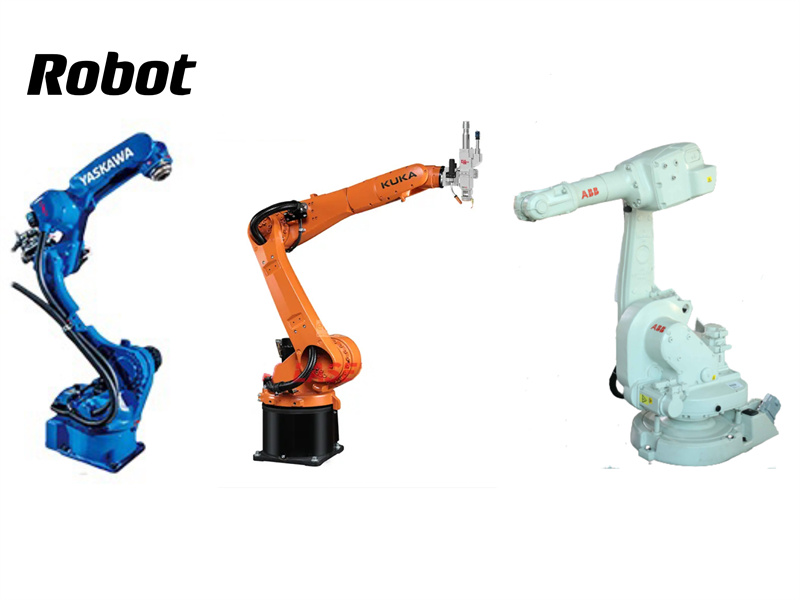

Robot welding machine

Get a free quoteBy automating welding processes, companies are becoming more environmentally-friendly. The process reduces inconsistent welds compared to manual welding —many companies investing in welding automation have benefited from expanding in-house capability and reducing the need to outsource.

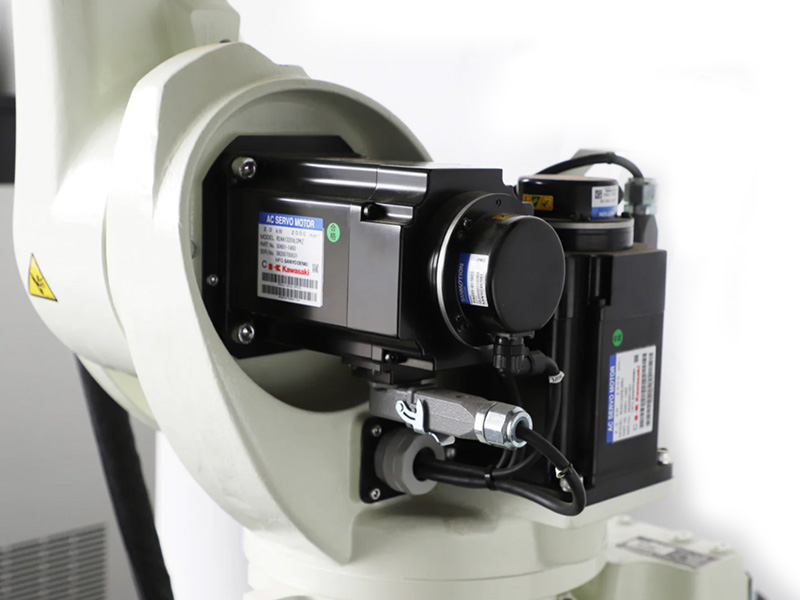

1. Use the manipulator to achieve barrier-free welding operations

2. Provides higher quality welds and more efficient processes

3. Easy to learn and safer, no need for professional welders.

4. Efficient and stable maintenance-free, can work 24 hours a day

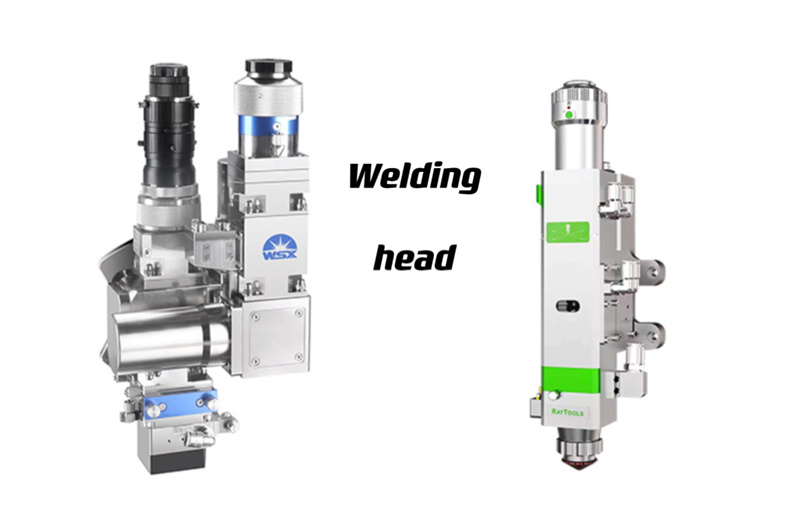

5. Suitable for spot welding, tailor welding, stitch welding, seam welding, etc.

Video

Technical Parameter

| Laser wavelength | 1080(±10)nm | ||

| Output fiber length | 10M | ||

| Max laser power | 1000W | 1500W | 2000W |

| Rated power | 10KW | 12KW | 15KW |

| Supply voltage(V) | 220V/50HZ | 220V/50HZ | 380V/50HZ |

| Spot adjustment range | 0.1-5MM | 0.1-5MM | 0.1-5MM |

| Laser frequency | 1-10000HZ | 1-10000HZ | 1-10000HZ |

| Cooling system | Cw1000 | Cw1500 | Cw2000 |

| Observing system | CCDor Red light | ||

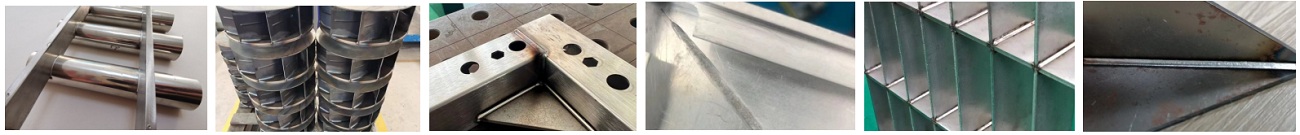

Application

It can be widely used in complex and irregular welding processes in kitchen cabinets and bathrooms, stairs, shelves, ovens, stainless

steel door and window guardrails, distribution boxes, stainless steel furniture and other industries.

Production Facility

Robot welding machine

Robot welding machine