- No.609, Centre Of Huijin Nanxiang, Yinxiang Road, Nanxiang Town, Jiading District, Shanghai, China

- sherry@sanmachines.com

- +86-18616767021

Advances in laser welding !

Fiber laser welding is touted as the latest advance in manual process options; capable of welding up to 6mm thickness across a range of metallic materials; offering 4x weld speed, low distortion and a pre/post-cleaning function, whilst being easier to use than its conventional arc-welding counterparts. So, is it as good as its manufacturers suggest?

Laser welding technology has gradually developed and advanced since 2000, and since then the introduction of lower-cost, more compact laser power systems has led to more affordable equipment from multiple suppliers, some offering power options up to 3kW. Suppliers include SAN LASER, the earliest laser welding manufacturer in China. Their YAG, fiber, and pulse welding products are very mature.

SAN LASER SAID response to the laser welding system has been positive. The technology stands out because it’s much smaller than other “portable” units produced overseas, which are about the size of a small refrigerator, and helps even novice welders get up to speed more quickly than they would with more traditional arc welding processes. For instance, laser welding doesn’t impart as much heat as TIG welding does, which makes it easier for a less experienced welder to take on a job with thin metals. In another example, welders don’t have to be as concerned with prebrushing or grinding down the work surface because laser welding doesn’t require the metal to be as clean as would be needed with the MIG welding process. Additionally, the built-in cosmetic pass feature provides a fast and noncontact method to improve postweld aesthetics, and an upcoming surface cleaning option will provide preweld surface preparation anywhere on the material surface.

“Experienced welders are making high-quality welds in a matter of hours and can improve further by adjusting and saving settings,” SAN LASER said. “For novices, it will take a bit longer to master, but they are going to be able to make the same types of welds using the preinstalled settings or those saved by more seasoned operators. Then it’s simply up to the novice to hold the gun properly and move it at the right speed.”

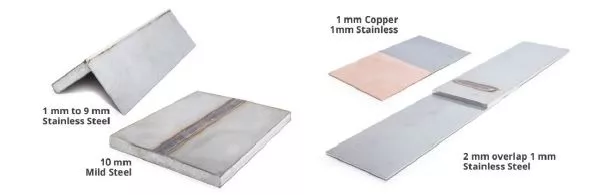

Welding of thick, thin, reflective, and dissimilar metal, which is difficult or even impossible with traditional arc welding methods, can be done with a laser.

Laser welding units also have some built-in features to ensure safe use. The system is designed with an interlock that requires the tip of the welding head to be in contact with the material during the welding process. If the tip is not touching the part, the laser turns off. This ensures that the laser is aimed at the metal workpiece. Furthermore, using the welding gun requires two steps: one button to enable operation and another to start the laser.

Related product links

Welder News

Welder News