- No.609, Centre Of Huijin Nanxiang, Yinxiang Road, Nanxiang Town, Jiading District, Shanghai, China

- sherry@sanmachines.com

- +86-18616767021

Advantages and Applications of Handheld Fiber Laser Welding Machines!

In recent years, laser welding machines have become increasingly popular with metal product manufacturers. Because like laser cutting, many advantages of laser welding are being recognized and utilized to produce better quality products with higher production efficiency and lower costs. Laser welding technology is a versatile and cost-effective method for joining metal materials.

Laser welding technology is a non-contact and high-power density welding process that uses the energy emitted by a laser beam to join multiple pieces of metal materials together. Stainless steel kitchenware, environmental protection equipment, automotive parts, etc. are some common areas where laser welding technology is widely used. This article introduces the advantages and applications of fiber laser welding machines so that you can better understand the characteristics of laser welding technology.

The precise control of laser welding machines offers users several advantages over traditional welding methods:

1.Fast welding speed: Laser welding is a very fast technology. Depending on the type and power of the laser used, thin-section materials can be welded at speeds of several meters per minute.

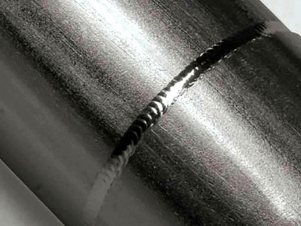

2.Weld strength: Laser welds are narrow, have a good depth-to-width ratio, and are stronger.

3.Heat-affected zone: The heat-affected zone is limited, and the surrounding material is not annealed due to rapid cooling.

4.Precision work: The small, tightly controlled laser beam allows precise micro-welding of micro-components.

5.Deformation: The parts have minimal deformation or shrinkage.

6.No contact: There is no physical contact between the material and the laser head.

7.Single-sided welding: Laser welding can replace spot welding, which only requires access from one side.

8.Waste: Laser welding is controllable and produces a low amount of waste.

Suitable for a wide range of metal materials and thicknesses: Using lasers, many different materials can be welded or joined, including steel, stainless steel, aluminum, titanium, and nickel alloys. Furthermore, using steel as an example, the thickness of weldable material can vary from less than a millimeter to approximately 30 millimeters, depending on the type and power of the laser used.

The unique characteristics of laser welding give it significant advantages over other forms of welding, which can be exploited in a variety of ways:

Precision parts: Lasers are ideal for welding delicate and precise metal parts, and produce minimal internal stress due to minimal heat input.

Medical devices: Non-contact welding, no welding spatter, ensures hygiene when welding medical devices.

Processed parts: Lasers are ideal for joining processed parts, and minimal deformation due to low heat input.

Valuable items: Precise controllability and negligible heating effects make it ideal for welding high-value, high-precision parts.

SAN LASER fiber laser welding machine uses a handheld welding head, which has the characteristics of no consumables, small size, flexible processing, and low operation and maintenance costs. If you need to know more, you can communicate us online.

Welder News

Welder News