- No.609, Centre Of Huijin Nanxiang, Yinxiang Road, Nanxiang Town, Jiading District, Shanghai, China

- sherry@sanmachines.com

- +86-18616767021

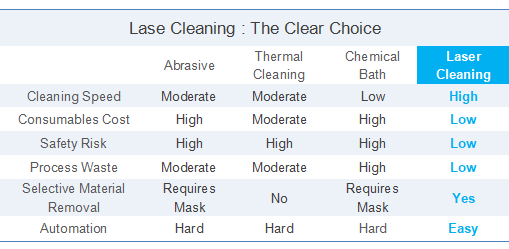

Advantages and applications of laser cleaning!

· What is Laser Cleaning?

Laser cleaning, also known as laser material removal, is an advanced method of eliminating material from a surface achieved through the precise manipulation of a scanned laser beam. This process utilizes laser thermal shock, which effectively peels off, vaporizes, sublimates, or burns away unwanted waste material without causing harm to the substrate. Laser cleaning is used across a variety of industries to remove unwanted surface materials like coatings, paints, rust, oil, and for surface preparation for welding and coating.

· Advantages of Laser Cleaning

Non-Contact Process

Laser cleaning is a remote process that enables precision material removal, virtually eliminating damage to the underlying material.

Selective Cleaning

Laser cleaning is highly precise and targets only the area to be cleaned, eliminating additional steps like masking.

Safe

Laser cleaning is easily automated and in most cases requires no abrasive materials or chemical solvents, reducing noise and eliminating exposure to hazardous materials.

Sustainable

Laser cleaning is a highly energy efficient process that requires no cleaning media, dramatically reducing material handling requirements and process waste.

Easier, More Flexible Material Removal

The advantages of laser cleaning can benefit a wide variety of industries and processes.

From coatings to contaminants and from flat to complex parts, laser cleaning offers the flexibility and ease of automation to optimize your productivity.

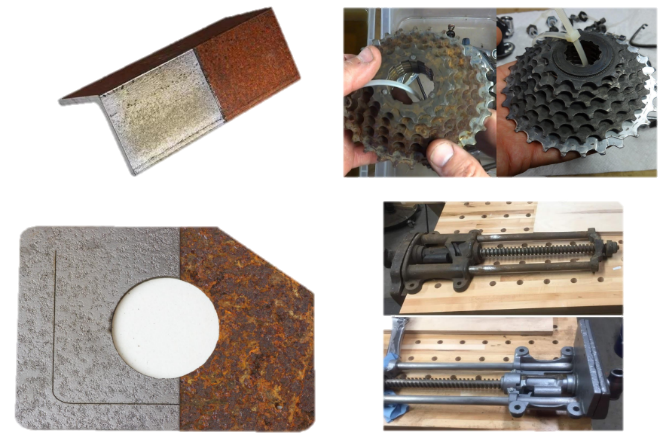

· Laser Cleaning Optimizes A Wide Variety of Applications

General Manufacturing

Laser ablation is an easier, faster method of surface preparation and removing a range of materials including coatings, paints, and surface contaminants like rust. A wide variety of industries benefit from the effectiveness of laser cleaning and surface preparation processes.

Safer and more environmentally friendly than alternative methods

No harm to underlying material

Precise area targeting with no need for masking or additional setup

Aerospace Applications

Laser cleaning is an effective and established method for removing dirt, grime, and coatings from aircraft components like tubines and wheels. Compared to alternatives like grit blasting and acid wash, laser cleaning dramatically increases productivity and efficiency.

Significantly higher process speeds

Higher efficiency and reduced operating costs

Less waste generated

Nuclear Decontamination

Laser cleaning is a highly effective method of decontaminating radioactive objects and surfaces that vaporizes pollutants before removing them via fume extraction. Laser nuclear decontamination is growing in popularity due to a variety of benefits.

Capable of achieving a 100% decontamination factor

No harm to underlying material

Easy-to-handle process waste

Medical Device Sterilization

Laser cleaning is an effective method of sterilization for medical devices and surgical instruments, rapidly removing residues and contaminants.

Full sterilization for critical medical instruments

High process speeds

No harm to underlying material

Food & Beverage Industry

Laser cleaning enables the food and beverage industry to effectively clean conveyor belts, packaging machinery, and other critical equipment to ensure hygienic production environments.

Easy to integrate method of equipment sterilization

Reduced waste handling requirements

Flexible cleaning for a variety of equipment

Related product links

Welder News

Welder News