- No.609, Centre Of Huijin Nanxiang, Yinxiang Road, Nanxiang Town, Jiading District, Shanghai, China

- sherry@sanmachines.com

- +86-18616767021

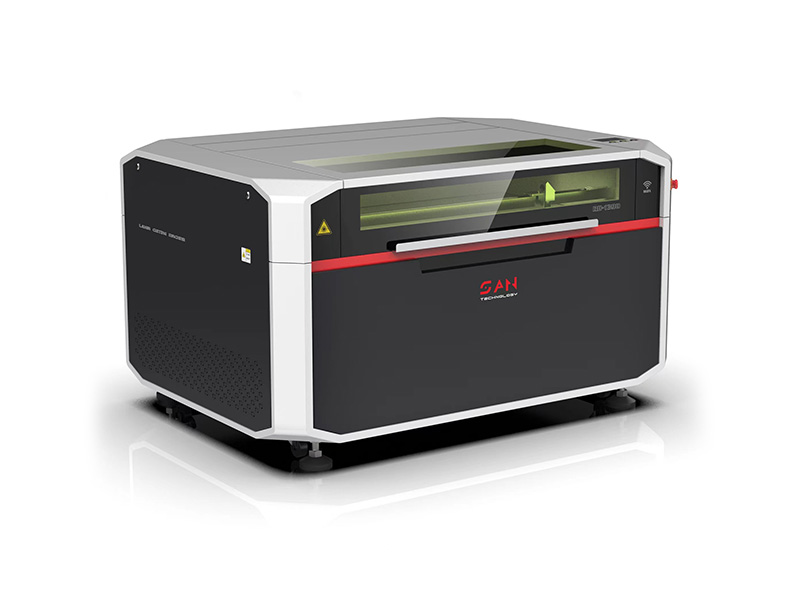

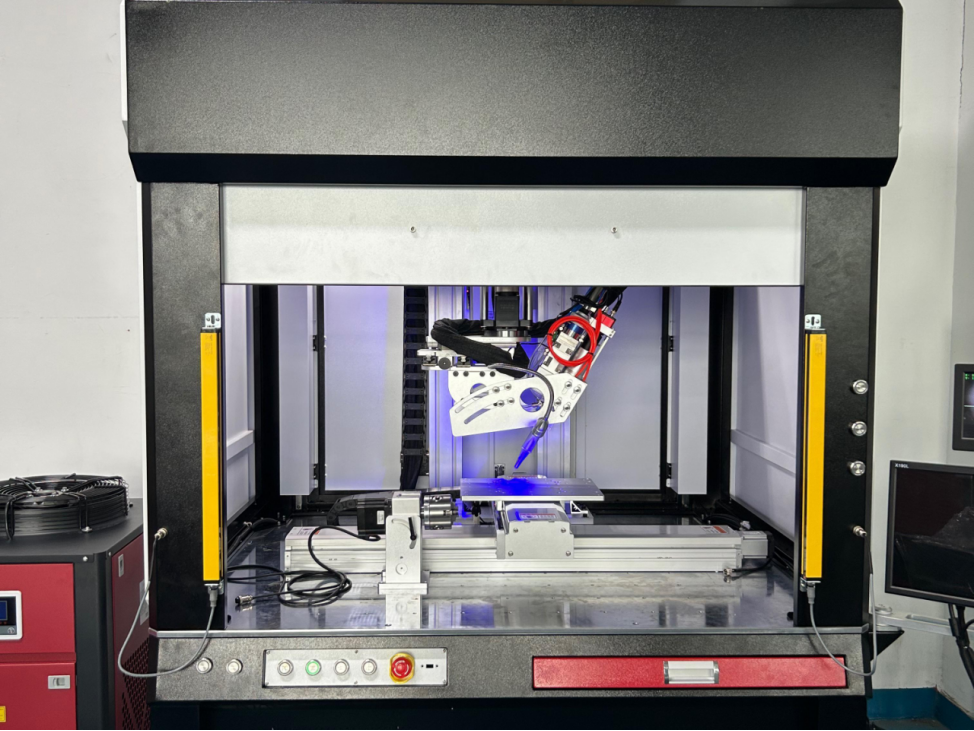

Advantages of automatic platform laser welding machine!

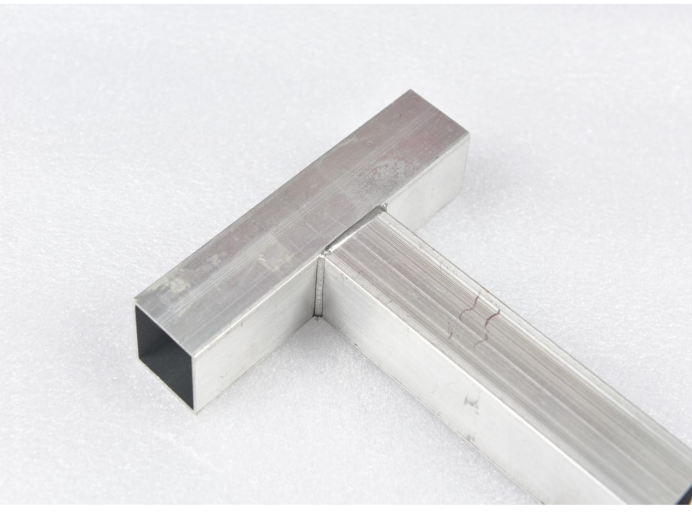

Compared with traditional welding, automatic platform laser welding machine has the advantages of high power density, concentrated energy, low heat input, narrow weld and small deformation. Moreover, after focusing the laser beam, a very small spot can be obtained, which can be precisely positioned. These characteristics make laser seam welding more suitable for welding small-sized workpieces than other welding methods. For laser welding of ultra-thin stainless steel materials, since the material is very thin, it is easy to vaporize and perforate. In order to obtain a continuous weld without burn-through, the key is to accurately control the parameters.

The main parameters that affect the quality of laser welding are welding current, pulse width, pulse frequency, etc., and their effects are mainly as follows:

(1)As the current increases, the width of the weld increases, spatter gradually appears during the welding process, oxidation occurs on the weld surface, and it feels rough.

(2) As the pulse width increases, the width of the weld seam also increases. Changes in pulse width have a very significant impact on the laser welding effect of stainless steel ultra-thin plates. A slight increase in pulse width may cause the sample to be oxidized and burned through.

(3)As the pulse frequency increases, the overlap rate of the weld points increases, and the weld width increases first and then remains basically unchanged. Under a microscope, the weld becomes smoother and more beautiful. However, when the pulse frequency increases to a certain value, the welding process spatters seriously, the weld becomes rough, and oxidation occurs on the upper and lower surfaces of the welded parts.

(4)Positive defocus is suitable for laser welding of ultra-thin plate materials. Under the same defocus amount, the weld surface obtained by positive defocus laser welding is smoother and more beautiful than that obtained by negative defocus.

Related product links

Welder News

Welder News