- No.609, Centre Of Huijin Nanxiang, Yinxiang Road, Nanxiang Town, Jiading District, Shanghai, China

- sherry@sanmachines.com

- +86-18616767021

Welding process classification of handheld laser welding machine

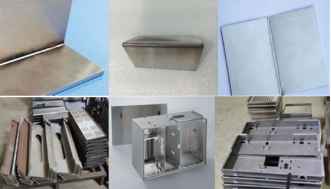

Different laser welding methods are used according to the different welding requirements of different products. Our common laser welding methods include butt welding, lap welding, female fillet welding, male fillet welding, spot welding, fillet welding, etc.

Product advantages of handheld laser welding machine

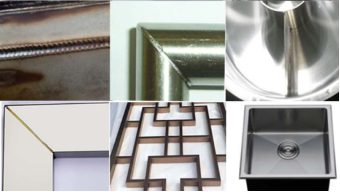

1)The control function is simple and easy to understand, with a button-type design, and it can be used immediately after turning on the machine. The laser beam quality is excellent, the welding speed is fast, and the weld is firm and beautiful, providing users with an efficient and perfect welding solution. The weld points are smooth and beautiful, and the welds are flat and free of pores.

2) The working mode of the handheld fiber optic welding machine is hand-held welding, which is flexible and convenient, and the welding distance is longer. The welding affected area is small, and will not cause deformation, blackening, or traces on the back. In addition, the welding depth is large, the welding is firm, and the melting is sufficient.

3) Suitable for various complex welds, handheld welding head, overcome the limitations of the workbench. The handheld welding gun can weld any part of the workpiece at any angle. High photoelectric conversion rate, low energy consumption, long-term use can save a lot of processing costs.

4) The integrated application of handheld laser welding machine is relatively convenient and extensive, such as common laser welding robot workstation, XY axis automatic laser welding machine, etc., which can realize the intelligent automatic welding needs of laser welding machine.

Related product links

Welder News

Welder News