- No.609, Centre Of Huijin Nanxiang, Yinxiang Road, Nanxiang Town, Jiading District, Shanghai, China

- sherry@sanmachines.com

- +86-18616767021

Analysis of the effect of color laser marking on stainless steel!

The research on color laser marking of stainless steel materials is mainly aimed at laser equipment manufacturers to expand the application field of laser marking machines and expand the sales market of marking machines; at the same time, for the stainless steel products industry, the application of color laser marking can add colorful marking graphics, which can greatly increase the product added value of stainless steel products and enhance the international competitiveness of domestic stainless steel products.

There are three ways to study the principle of color development of colored stainless steel:

One is to generate colored oxides;

The second is to generate a very thin layer of colorless and transparent oxide film on the surface of stainless steel under chemical, electrochemical or laser action. The oxide film produces an interference effect, which can show color on the surface;

The third is a mixed state where colored oxides and oxide films exist at the same time.

Interaction

Study the interaction between laser and material, including the absorption of laser by metal materials and the heating process of laser on materials. Through the laser color marking experiment, observe the surface microstructure of stainless steel color laser marked samples and analyze the changes in the marking process.

Laser thermal effect

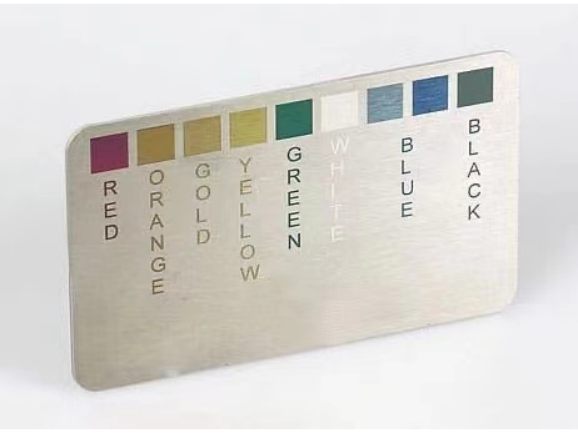

Study the laser thermal effect generated on the surface of stainless steel under the action of laser. Through the calculation of the laser thermal effect equation, it is concluded that the laser energy density is proportional to the film thickness. Experiments have shown that with the increase of laser energy, the color of the stainless steel surface changes in the following color sequence: orange-red-purple-blue-green-blue-green-green-yellow-green-yellow-orange-red...

It is instructive for laser equipment manufacturers to design special stainless steel color laser marking machines. At present, the marking parameters of common laser marking machines are: current, pulse repetition frequency, pulse width, point spacing, line spacing and marking speed, etc., which have no direct correspondence with the laser generation of stainless steel color. The marking parameters can be changed to parameters that have a direct impact on the color change of the stainless steel surface, such as: laser energy, pulse repetition frequency, pulse width, etc., to reduce the variable parameters, improve the simplicity and reliability of adjusting the generated color, and make it possible for stainless steel laser color marking to enter mass industrial production.

Company News

Company News