- No.609, Centre Of Huijin Nanxiang, Yinxiang Road, Nanxiang Town, Jiading District, Shanghai, China

- sherry@sanmachines.com

- +86-18616767021

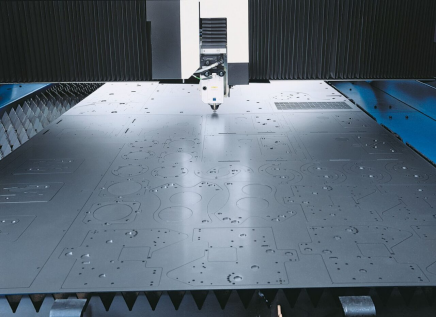

Challenges and future trends of laser cutting!

Current Challenges in Laser Cutting

There will always be challenges as new technology is introduced, despite the exciting prospects ahead. Key concerns include:

Improving Workplace Safety

Skilled workers, especially laser operators, remain invaluable in the manufacturing process, even with advancements in automation. As technology evolves, so does our knowledge and ability to enhance safety. This requires ongoing improvements to safety protocols, including training and the adoption of new tools.

Cost-Effectiveness for Smaller Businesses

Investing in advanced technology can be challenging for smaller, locally run businesses. Often, outsourcing to manufacturers that offer a range of laser cutting services at competitive prices can be a more cost-effective solution.

Demand for Skilled Workers

As new laser cutting technologies become the industry standard, the demand for skilled workers who understand best practices also increases. Fortunately, augmented reality (AR) and virtual reality (VR) technologies offer innovative solutions for training, providing near hands-on experience for both new trainees and existing employees.

2. Laser cutting is a high-energy, non-contact processing with good density controllability.

(i) Narrow straight-edge slit;

(ii) Small heat-affected zone adjacent to the cutting edge;

(iii) Minimal local deformation. Secondly, the laser beam does not exert any force on the workpiece, and it is a non-contact cutting tool, which means

(iv) There is no mechanical deformation of the workpiece;

(v) There is no tool wear, and there is no problem of tool conversion;

(vi) The hardness of the cutting material does not need to be considered, that is, the laser cutting ability is not affected by the hardness of the material being cut, and any hardness of the material can be cut. Secondly, the laser beam is highly controllable and has high adaptability and flexibility.

Future Laser Cutting Trends

Laser cutting technology will only continue to expand with some exciting new prospects on the horizon. Here are a few notable trends for the market:

AI Integration

Artificial Intelligence will drive the industry, enabling incredibly precise parameters and maximising efficiency in the workload for manufacturers.

Enhanced Efficiency and Cost-Effectiveness

Lasers will become more energy-efficient and powerful at reduced costs, broadening their range of capabilities.

Growing Role Across Industries

Laser cutting’s role within various industries will continue to grow, demonstrating its value even in the fashion market, and increasing accessibility to many more. Most notably, it has been instrumental in providing groundbreaking contributions to healthcare and aerospace components, demonstrating the advantages of laser cutting.

Hybrid Laser Cutting

The ability to combine different processes through hybrid laser cutting will allow for more diverse projects and materials. Combined with 3D laser cutting, which is steadily increasing in popularity, it will enable more intricate designs with limitless possibilities.

Related product links

Cutter News

Cutter News