- No.609, Centre Of Huijin Nanxiang, Yinxiang Road, Nanxiang Town, Jiading District, Shanghai, China

- sherry@sanmachines.com

- +86-18616767021

Comparison of CO2, YAG and fiber laser cutting machines!

I believe that after reading this article, you will have a general understanding of the cutting materials, cutting thickness, watts, and corresponding industries of the laser cutter, and you will not make blind choices when purchasing.

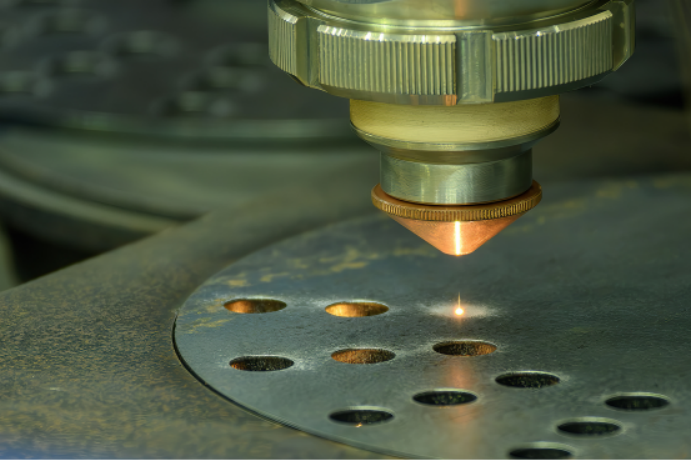

Let's first introduce the principle of the fiber laser cutting machine

Laser cutting is to vaporize the plate instantly at high temperature, and the auxiliary gas blows away the vaporized plate slag at the same time to separate it, and complete the cutting process of the plate with the mechanical movement of the machine.

The laser emitted by the laser can get a 0.1-0.3 mm light spot after focusing. This light spot has a very high energy density, reaching one million watts per square centimeter. Such energy density can make many materials be heated, melted, and even evaporated in an instant.

Assuming that the laser power is 1000W, the diameter of the light spot after focusing is 0.1 mm, and the energy accumulated per square centimeter is

E= 1000W/π(0.01/2)2 =12,700 kilowatts/cm2

Processing characteristics of fiber laser cutting machine

1. Non-contact processing, small heat-affected zone on processed materials, flexible processing

2. Narrow cutting gap

3. Fast cutting speed and good precision

4. Five mechanical stresses, no burrs

5. No tool loss and contact energy loss, no need to replace tools

6. The beam runs without inertia, and high-speed cutting can be implemented

7. Multi-station operation can be realized, and automation can be easily realized

8. Low noise

9. Good laser cutting surface quality and smooth cutting edges

Classification of laser cutting machines

Laser classification: CO2, YAG, optical fiber

Movement mode: two-dimensional platform, three-dimensional space, pipe

YAG solid-state cutting machine: the leading product of the cutting machine in the early stage, with few real faces at present. It generates laser through xenon lamp tubes, and can cut high-reflective materials such as copper and aluminum.

Advantages: high laser intensity, universal for cutting plates, low price;

Disadvantages: high power consumption, high consumables, low beam quality, average cutting effect, and regular dimming and maintenance are required.

CO2 laser cutting machine: can achieve thick plate cutting, carbon dioxide laser, has unique advantages for thick plate cutting.

Advantages: mature earlier than optical fiber, can effectively complete the perfect cutting of thick plates, can cut stainless steel with a thickness of more than 20 and carbon steel with a thickness of more than 10, mostly used for cutting hulls, etc.;

Disadvantages: high price and high cost of use

Comparison of fiber laser, YAG solid-state laser, and CO2 laser

Fiber laser

The electro-optical conversion efficiency is 30%, the output power is 500-35000W, the semiconductor pump life is greater than 200000, no maintenance is required, it is suitable for flexible processing, and has good stability. The steel absorption rate is 35%, and the aluminum absorption rate is 7%. There is only one part that needs to be replaced, that is, if the high-brightness broadband single-core semiconductor laser exceeds 200,000 hours of pumping time, if one of the semiconductors is damaged, it only costs 300-500 US dollars to replace it, because each semiconductor pump is independent of each other.

YAG solid-state laser

The electro-optical conversion efficiency is 3%, the output power is 500W/600W, the life of the semiconductor pump is 1000, and it needs frequent maintenance. The flexible addition is far behind the fiber laser, and the stability is poor. Its steel absorption rate and aluminum absorption rate are 35% and 7%, and its lamp can work continuously for less than one thousand hours. In other words, it needs to be replaced at any time if it exceeds one thousand hours.

CO2 laser

The photoelectric conversion efficiency is 10%, the output power is 2KW/4KW, the semiconductor pump life is NA, maintenance is required, it is not suitable for flexible processing, and the stability is OK. Among them, the absorption rate of steel is 12%, and the absorption rate of aluminum is 2%. The replenishment of working gas requires timely replacement of parts.

At this point, do you have a general understanding of these three types of laser cutters? Next, I believe that you will be more comfortable choosing according to your needs. In addition, choosing a good laser cutter is the key. Choosing a good manufacturer will not only help you save a lot of money on maintenance, but SAN LASER will also teach you cutting technology step by step.

Related product links

Cutter News

Cutter News