- No.609, Centre Of Huijin Nanxiang, Yinxiang Road, Nanxiang Town, Jiading District, Shanghai, China

- sherry@sanmachines.com

- +86-18616767021

Differences Between Nanosecond, Picosecond, and Femtosecond Lasers!

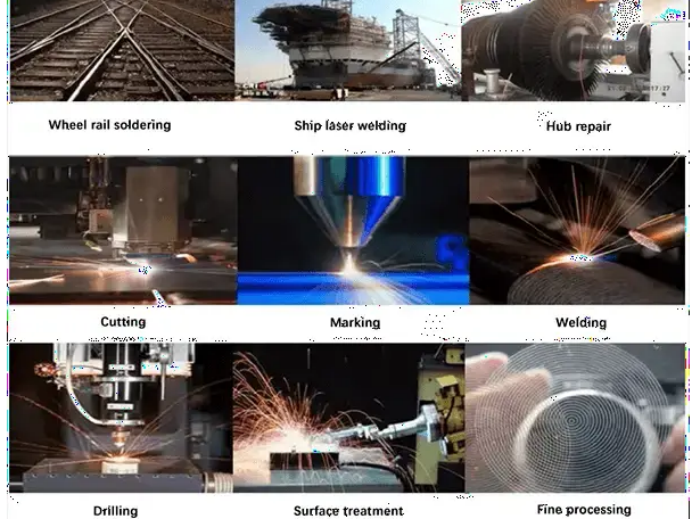

Lasers are used in a wide range of industries, and their effectiveness depends on pulse duration. In this article, we will discuss three types of lasers that are primarily differentiated by pulse duration: nanosecond, picosecond, and femtosecond lasers.

1.Nanosecond lasers have a pulse duration of 10 -9 seconds. These lasers have been in use for a long time and are suitable for a variety of material processing applications. However, their longer pulse durations can cause thermal damage in some cases.

2.Picosecond lasers have shorter pulse durations of 10 -12 seconds. The shortened pulse duration minimizes thermal damage and enables more precise material processing. Therefore, picosecond lasers are preferred for applications that require more precision and less thermal impact on the material being processed.

3.Femtosecond lasers have the shortest pulse durations of 10 -15 seconds. Because the laser's pulse duration is less than the conduction time of the target material, its ultrafast pulses offer unique material processing opportunities. This property allows for the use of "cold" processing techniques, where material is removed by sublimation without thermally induced damage.

All three laser types are pulsed lasers, known for their ultrashort pulse durations. The main advantage of ultrafast lasers is that they can minimize thermal effects and increase the precision of material processing.

Each laser has its own advantages and applications, and you can choose according to your needs.

Related product links

Company News

Company News