- No.609, Centre Of Huijin Nanxiang, Yinxiang Road, Nanxiang Town, Jiading District, Shanghai, China

- sherry@sanmachines.com

- +86-18616767021

Do you know the importance of annealing process for cutting machines?

We are SanLaser, a leading manufacturer of high-quality fiber laser cutting machines. We are writing to introduce our robust and precise machines, built with a focus on long-term stability and cutting accuracy.

At SanLaser, we independently produce our machine beds, many suppliers source their machine beds from our company. While many machine beds on the market weigh less than 3 tons, our standard 3015 machine bed typically weighs over 4 tons. With our in-house production capabilities, we can better control machine quality, resulting in a total machine weight exceeding 6 tons, providing exceptional stability. In addition, our machine frames are constructed using thick steel plate welding and undergo a crucial stress relief annealing process to ensure exceptional rigidity and resistance to deformation, even after prolonged use.

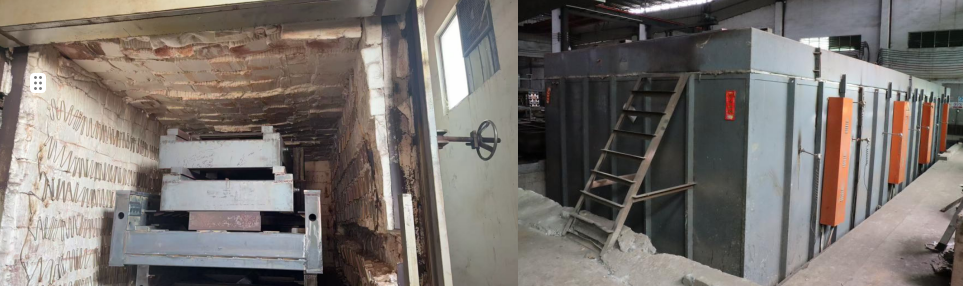

1.Stress Relief Annealing Process

This involves a stepwise temperature control method that effectively eliminates residual stresses from casting, forging, welding, and machining. By preventing deformation and cracking, this process guarantees the structural integrity of our machines.

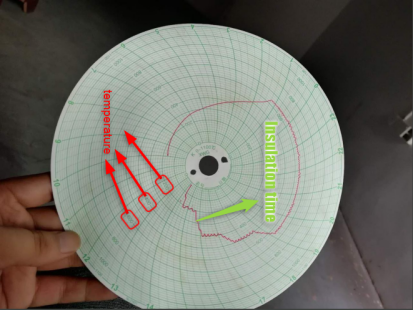

Annealing Process Parameters

· Total Duration: 20-24 hours

· Heating Stages (6 steps):

Step | Temperature Range | Holding Time |

1 | Room temperature → 160°C | 1 hour |

2 | 160°C → 250°C | 1 hour |

3 | 250°C → 360°C | 1 hour |

4 | 360°C → 480°C | 1 hour |

5 | 480°C → 560°C | 1 hour |

6 | 560°C → 630°C | 6 hours |

Temperature rise time diagram:

· Cooling Phase:

Sealed Furnace Slow Cooling: Natural cooling for 9 hours to room temperature after sealing.

Temperature Equalization: Open furnace door slightly until internal/external temperatures equalize, then fully open.

Vibration Aging: Additional hours of vibration aging for residual stress reduction (over 90-95%)

2. Machine Tool Manufacturing Standards

Machine Bed Structure

ü Steel Plate Welding: High-rigidity multi-layer welding

ü Square Tube Welded Grid Structure: Enhanced torsional resistance and stability

Machining Precision

ü Possessed by large gantry milling machines with ±0.025mm accuracy per bed,while many processing factories on the market only around ±0.10mm. This is the difference.

Quality Control

· Temperature Control: The entire process is controlled via electric furnaces, adhering to the European EN 1011-2 annealing standard.

· Data Archiving: Each batch's annealing curve data is archived for traceability.

3.Premium Configurations for Superior Performance

Component | Brand/Model | Advantage |

Laser Rack | TAIWAN JT | High rigidity & alignment |

Guide Rail | TAIWAN DTX | Smooth motion, low friction |

Resonator | MAX/RAYCUS (top brands) | High power, long lifespan |

Servo Motors | CYPCUT (1.7KW Y / 1.1KW X) | Precise motion control |

Reducer | Germany TECHMECH/MOTOVARIO France | High torque, low noise |

Cutting Head | Raytools | Auto-focus, anti-spatter |

CNC System | CYPCUT 6000 | User-friendly, most famous in market |

4. Wide Range of Models (Customizable to Your Needs)

Popular Models: 3015, 4015, 4020, 5015, 6015, 6020, 6025, 12025, 13025, 13030, 14035, 28040

Why Partner with Us?

✅ Direct Manufacturer: No middlemen – competitive pricing & quick customization.

✅ Proven Track Record: Trusted by suppliers worldwide for our machine beds and full systems.

✅ Service Support: Global technical assistance + 1-year warranty.

Ready to Upgrade Your Cutting Efficiency?

Request a Quote Today: Share your material specs, cutting requirements, or preferred model (e.g., 3015/4020), and we’ll provide a tailored proposal.

P.S. Limited-time promotion for first-time buyers – inquire now for exclusive discounts!

Related product links

Cutter News

Cutter News