- No.609, Centre Of Huijin Nanxiang, Yinxiang Road, Nanxiang Town, Jiading District, Shanghai, China

- sherry@sanmachines.com

- +86-18616767021

Factors affecting laser welding quality!

Laser welding is currently the main method recommended for high-end battery welding. Laser welding is a process in which a high-energy laser beam irradiates the workpiece, causing the working temperature to rise sharply, the workpiece to melt and reconnect to form a permanent connection. The shear strength and tear strength of laser welding are relatively good. The conductivity, strength, airtightness, metal fatigue and corrosion resistance of battery welding are typical welding quality evaluation criteria.

There are many factors that affect the quality of laser welding. Some of them are extremely easy to fluctuate and have considerable instability. How to correctly set and control these parameters so that they are controlled within a suitable range during high-speed continuous laser welding to ensure welding quality. The reliability and stability of weld formation are important issues related to the practical application and industrialization of laser welding technology. The main factors affecting the quality of laser welding are welding equipment, workpiece conditions and process parameters.

1) The quality requirements of welding equipment for lasers are mainly beam mode, output power and stability. The beam mode is the main indicator of beam quality. The lower the beam mode order, the better the beam focusing performance, the smaller the spot, the higher the power density at the same laser power, and the greater the depth and width of the weld. Generally, the fundamental mode (TEM00) or low-order mode is required, otherwise it is difficult to meet the requirements of high-quality laser welding. At present, there are still some difficulties in the use of domestic lasers for laser welding in terms of beam quality and power output stability. Judging from the situation abroad, the beam quality and output power stability of lasers are already quite high and will not become a problem for laser welding. The biggest factor affecting the welding quality in the optical system is the focusing mirror. The focal length used is generally between 127mm (5in) and 200mm (7.9in). A small focal length is good for reducing the waist diameter of the focused beam, but it is easy to be contaminated and splashed during welding.

The shorter the wavelength, the higher the absorption rate; generally, materials with good conductivity have high reflectivity. For YAG lasers, the reflectivity of silver is 96%, aluminum is 92%, copper is 90%, and iron is 60%. The higher the temperature, the higher the absorption rate, which is a linear relationship; generally, surface coating with phosphate, carbon black, graphite, etc. can improve the absorption rate.

2) Workpiece condition

Laser welding requires the edge of the workpiece to be processed, the assembly has high precision, the spot and the weld are strictly aligned, and the original assembly accuracy of the workpiece and the spot alignment cannot change due to welding thermal deformation during the welding process. This is because the laser spot is small, the weld is narrow, and generally no filler metal is added. If the assembly is not strict and the gap is too large, the beam can pass through the gap but cannot melt the parent material, or cause obvious undercuts and depressions. If the deviation of the spot to the seam is slightly larger, it may cause incomplete fusion or incomplete penetration. Therefore, the gap between the assembly of the general plate and the deviation of the spot to the seam should not be greater than 0.1mm, and the misalignment should not be greater than 0.2mm. In actual production, sometimes laser welding technology cannot be used because these requirements cannot be met. To obtain a good welding effect, the allowable gap and overlap gap of the butt joint should be controlled within 10% of the thickness of the thin plate.

Successful laser welding requires close contact between the base materials to be welded. This requires careful tightening of the parts to achieve the best results. This is difficult to achieve on thin tab substrates because they are prone to bending and misalignment, especially when the tabs are embedded in large battery modules or components.

3) Welding parameters

(1) Impact on laser welding mode and weld formation stability The most important welding parameter is the power density of the laser spot, which affects the welding mode and weld formation stability as follows: as the laser spot power density increases from small to large, it is stable thermal conductivity welding, mode unstable welding and stable deep fusion welding. The power density of the laser spot is mainly determined by the laser power and the beam focus position when the beam mode and the focal length of the focusing mirror are constant. The laser power density is proportional to the laser power. The influence of the focal position has an optimal value; when the beam focus is at a certain position below the workpiece surface (within the range of 1 to 2 mm, depending on the plate thickness and parameters), the most ideal weld can be obtained. Deviating from this optimal focal position, the spot on the workpiece surface becomes larger, causing the power density to decrease. To a certain range, it will cause changes in the form of the welding process.

The influence of welding speed on the welding process form and stable parts is not as significant as that of laser power and focal position. Only when the welding speed is too high, the stable deep fusion welding process cannot be maintained due to too little heat input. In actual welding, stable deep fusion welding or stable thermal conduction welding should be selected according to the requirements of the weldment for the fusion depth, and mode unstable welding should be absolutely avoided.

(2) The influence of welding parameters on fusion depth within the range of deep fusion welding: within the range of stable deep fusion welding, the higher the laser power, the greater the fusion depth, which is about the relationship of 0.7 power; and the higher the welding speed, the shallower the fusion depth. Under certain laser power and welding speed conditions, the fusion depth is the largest when the focus is in the optimal position. If it deviates from this position, the fusion depth decreases, and even becomes mode unstable welding or stable thermal conduction welding.

(3) The influence of shielding gas. The main functions of shielding gas are to protect the workpiece from oxidation during welding; to protect the focusing lens from metal vapor contamination and liquid droplet sputtering; to disperse the plasma generated by high-power laser welding; to cool the workpiece and reduce the heat affected zone.

Shielding gas usually uses argon or helium. Nitrogen can also be used if the apparent quality requirements are not high. Their tendency to generate plasma is significantly different: Helium has a high ionization charge and fast thermal conductivity. Under the same conditions, it has a lower tendency to generate plasma than argon, so it can achieve a greater penetration depth. Within a certain range, as the shielding gas flow rate increases, the tendency to suppress plasma increases, and thus the penetration depth increases, but it tends to stabilize after reaching a certain range.

(4) Analysis of the monitorability of each parameter: Among the four welding parameters, welding speed and shielding gas flow rate are parameters that are easy to monitor and maintain stable, while laser power and focal position are parameters that may fluctuate during welding and are difficult to monitor. Although the laser power output from the laser is very stable and easy to monitor, the laser power reaching the workpiece will change due to the loss of the light guide and focusing system. This loss is related to the quality of the optical workpiece, the use time and the surface contamination. Therefore, it is not easy to monitor and becomes an uncertain factor in welding quality. The beam focal position is a factor that has a great impact on welding quality and is the most difficult to monitor and control among welding parameters. At present, in production, it is necessary to rely on manual adjustment and repeated process tests to determine the appropriate focal position to obtain the ideal penetration depth. However, during the welding process, due to workpiece deformation, thermal lens effect or multi-dimensional welding of spatial curves, the focus position will change and may exceed the allowable range.

For the above two situations, on the one hand, high-quality and high-stability optical components should be used, and they should be maintained regularly to prevent contamination and keep clean; on the other hand, it is required to develop real-time monitoring and control methods for the laser welding process to optimize parameters, monitor the changes in laser power and focus position reaching the workpiece, realize closed-loop control, and improve the reliability and stability of laser welding quality.

Finally, it should be noted that laser welding is a melting process. This means that the two substrates will melt during the laser welding process. This process is very fast, so the overall heat input is low. But because it is a melting process, fragile and high-resistance intermetallic compounds may be formed when welding different materials. The aluminum-copper combination is particularly prone to the formation of intermetallic compounds. These compounds have been shown to have a negative impact on the short-term electrical properties and long-term mechanical properties of microelectronic device lap joints. The impact of these intermetallic compounds on the long-term performance of lithium batteries is still uncertain.

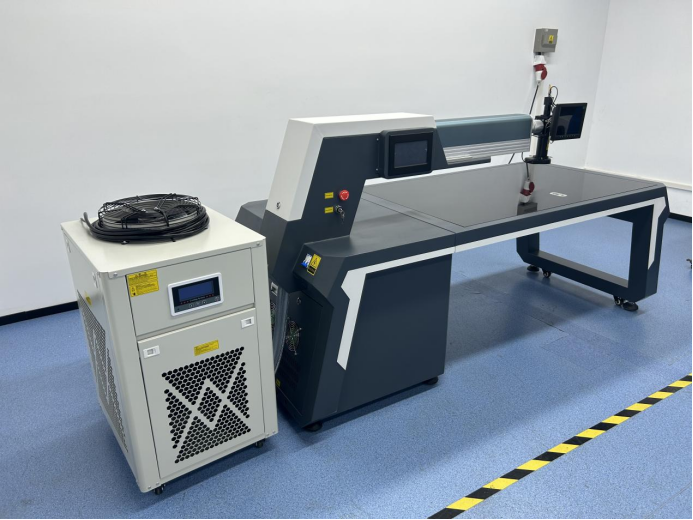

Related product links

Welder News

Welder News