- No.609, Centre Of Huijin Nanxiang, Yinxiang Road, Nanxiang Town, Jiading District, Shanghai, China

- sherry@sanmachines.com

- +86-18616767021

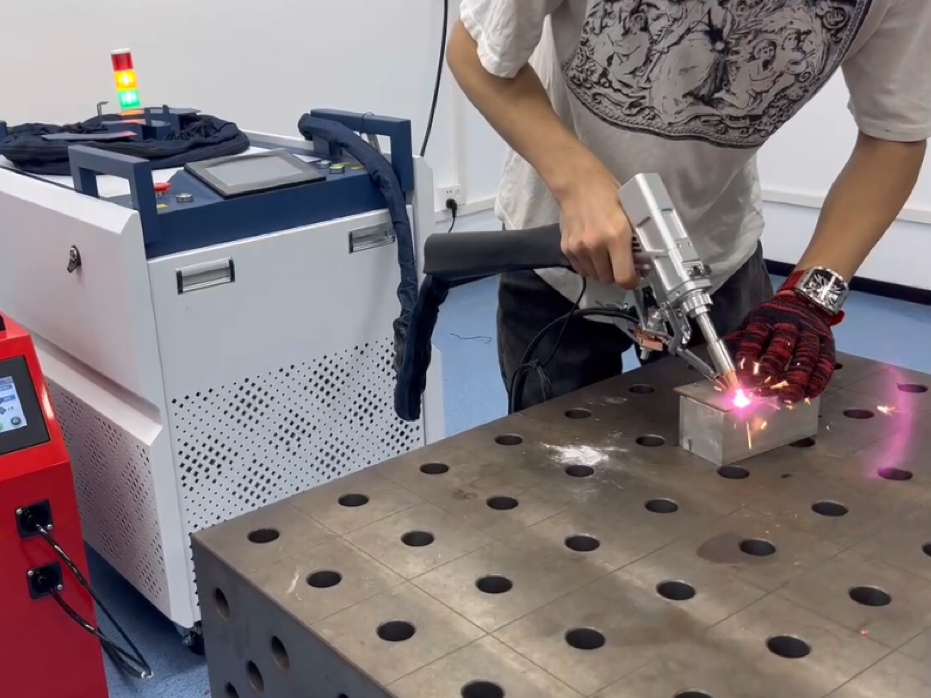

Factors affecting the penetration depth of laser welding machines

The factors that affect the penetration depth are mainly: shielding gas, laser power, welding speed, and material absorption value.

1. Shielding gas

Laser welding machines often use inert gas to protect the molten pool. When the surface oxidation of some materials can be ignored, protection can also be ignored. However, for most applications, helium, argon, nitrogen and other gases are often used for protection to prevent the workplace from oxidation during the welding process.

2. Laser power

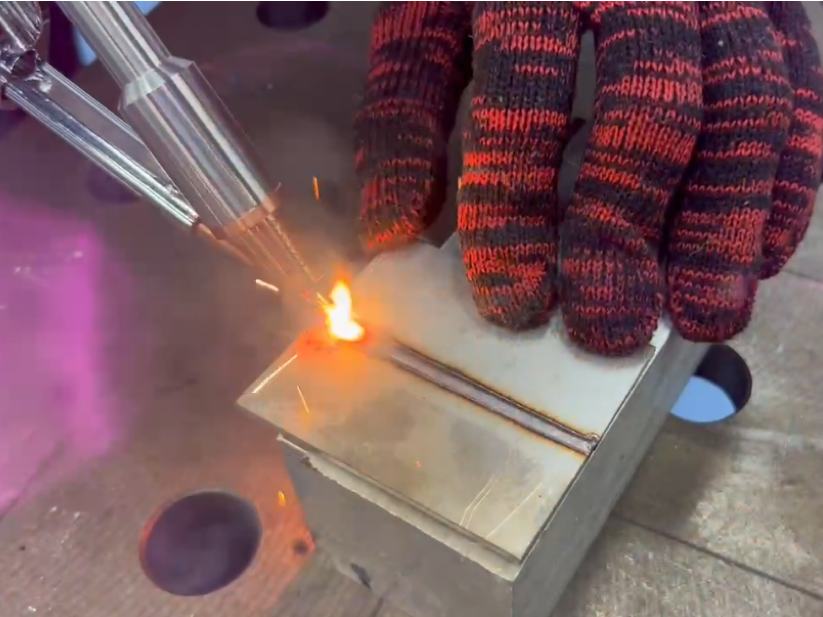

There is a laser energy density threshold in laser welding. Below this value, the penetration depth is very shallow. Once this value is reached or exceeded, the penetration depth will increase significantly. Only when the laser power density on the workplace exceeds the threshold, plasma will be generated, which indicates that stable deep penetration welding is in progress. The penetration depth of the laser welding machine is directly related to the beam power density and is a function of the incident beam power and the beam focal spot. Generally speaking, for a laser beam of a certain diameter, the penetration depth increases as the beam power increases.

3. Welding speed

Welding speed has a great influence on the depth of penetration. Increasing the speed will make the depth of penetration shallower, but too low a speed will lead to excessive melting of the material and welding through the workplace. Therefore, there is a suitable welding speed range for a certain material with a certain laser power and a certain thickness, and the maximum depth of penetration can be obtained at the corresponding speed value. The diffraction-limited spot size of the beam focus can be calculated according to the light diffraction theory, but due to the existence of focusing lens aberrations, the actual spot size is larger than the calculated value.

4. Material Absorption Value

The absorption of laser by materials depends on some important properties of materials, such as absorption rate, reflectivity, thermal conductivity, melting temperature, evaporation temperature, etc., among which the most important is absorption. There are two factors that affect the absorption of materials to laser beams: first, the resistivity of the material. After measuring the absorption of the polished surface of the material, it is found that the absorption of the material is proportional to the square root of the resistivity, and the resistivity changes with temperature; second, the surface state (or finish) of the material has a significant influence on the absorption of the beam, which has a significant effect on the welding effect.

Welder News

Welder News