- No.609, Centre Of Huijin Nanxiang, Yinxiang Road, Nanxiang Town, Jiading District, Shanghai, China

- sherry@sanmachines.com

- +86-18616767021

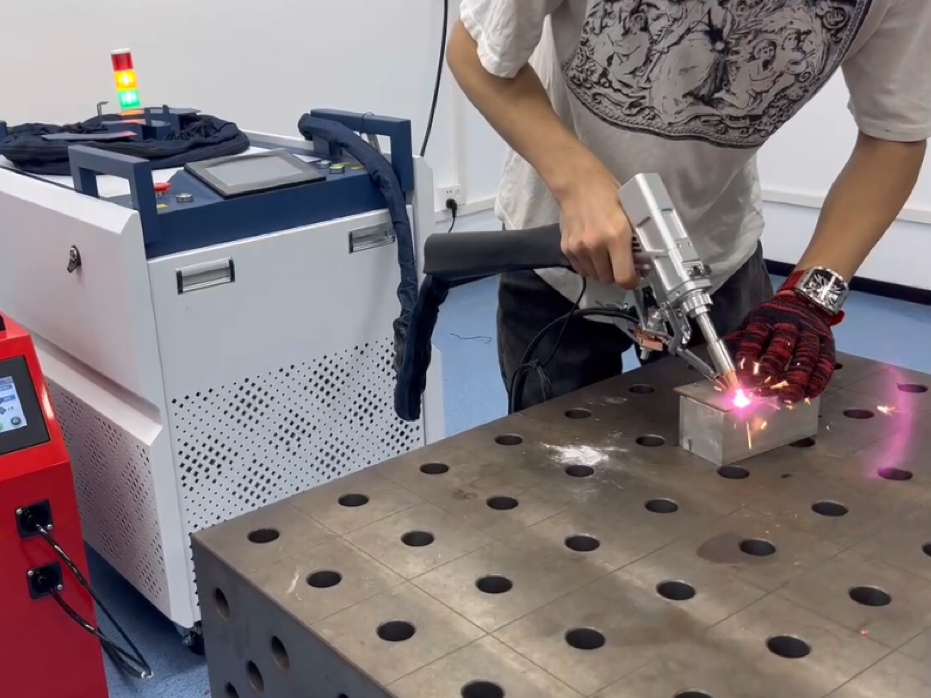

How to deal with problems in laser welding!

Laser welding has been widely used in various industries. While improving everyone's work efficiency, many problems are inevitable, resulting in unsatisfactory welding results.

So what are the ways to deal with different problems? You can refer to the following suggestions.

1. Welding deviation

The weld metal will not solidify in the center of the joint structure.

Causes of deviation: inaccurate positioning during welding, or inaccurate filling welding time and welding wire alignment.

Solution: adjust the welding position, or adjust the welding time and welding wire position, as well as the position of the lamp, welding wire and weld.

2. Weld depression

Weld depression refers to the phenomenon of depression on the surface of the weld metal.

Cause of depression: During brazing, the center of the weld is poor. The center of the light spot is close to the lower plate and deviates from the center of the weld, causing part of the parent material to melt.

Solution: Adjust the light wire matching.

3. Poor weld formation

Poor weld formation includes: poor weld corrugation, uneven and irregular weld, uneven transition between weld and parent material, poor weld, and uneven weld.

Causes of this situation: unstable wire feeding or discontinuous light during weld brazing.

Solution: Adjust the stability of the equipment.

4. Weld bead

When the weld track changes greatly, weld bead or uneven forming is easy to appear at the corner.

Cause: The weld track changes greatly and the teaching is uneven.

Solution: Weld under the optimal parameters and adjust the viewing angle to make the corner coherent.

5. Surface slag inclusion

Surface slag inclusion refers to: during the welding process, the surface slag that can be seen from the outside mainly appears between layers.

Analysis of the cause of surface slag inclusion:

A. When welding multiple layers and multiple passes, the interlayer coating is not clean; or the surface of the previous layer of weld is uneven or the surface of the weldment does not meet the requirements.

B. Improper welding operation techniques such as low welding input energy and too fast welding speed.

Solution:

A. Select a reasonable welding current and welding speed. The interlayer coating must be cleaned when welding multiple layers and multiple passes.

B. Grind the weld to remove the surface slag inclusion and repair welding if necessary.

Related product links

Welder News

Welder News