- No.609, Centre Of Huijin Nanxiang, Yinxiang Road, Nanxiang Town, Jiading District, Shanghai, China

- sherry@sanmachines.com

- +86-18616767021

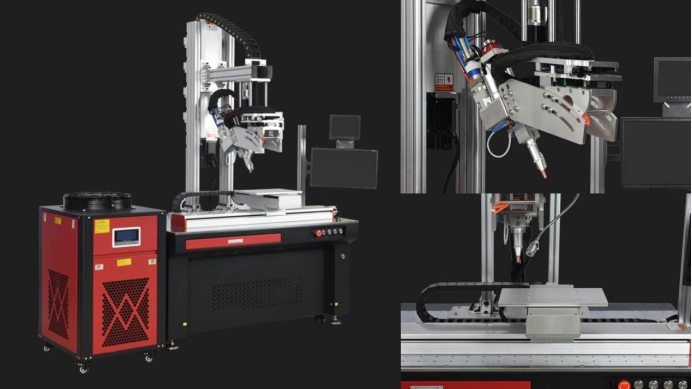

Innovative application of laser welding machine in welding water pipe joints in the sanitary ware industry!

In today's sanitary ware industry, product quality and workmanship are directly related to consumers' experience and satisfaction. As an important part of bathroom products, the quality and sealing of water pipe joints are particularly critical. With the advancement of science and technology, laser welding machines are gradually becoming the preferred equipment for welding water pipe joints in the sanitary ware industry with their high-precision, high-efficiency, and high-quality welding characteristics.

1. Technical advantages of laser welding machine

Laser welding machines use high-energy-density laser beams as heat sources to achieve melting and joining of materials through the interaction between laser and materials. Compared with traditional welding methods, laser welding has many significant advantages:

1. **High Precision**: The laser beam has a very small spot after focusing, which can achieve micron-level precision welding, ensuring the accurate welding position of water pipe joints and improving the overall quality of the product.

2. **High efficiency**: Laser welding is extremely fast and can complete the welding of a large number of joints in a short time, greatly improving production efficiency and reducing production costs.

3. **High quality**: During the laser welding process, the heat affected zone is small, the welding deformation is small, the weld is beautiful and the quality is stable, effectively avoiding common defects such as pores and cracks in traditional welding, and improving the sealing of water pipe joints and durability.

4. **High flexibility**: The laser welding machine is suitable for welding a variety of materials, including stainless steel, copper, aluminum and other common bathroom materials. At the same time, by adjusting parameters such as laser power and welding speed, it can adapt to the welding needs of water pipe joints of different specifications and shapes.

2. Application examples of laser welding machines in the sanitary ware industry

In the sanitary ware industry, laser welding machines have been widely used in the welding production of water pipe joints. The following are some specific application examples:

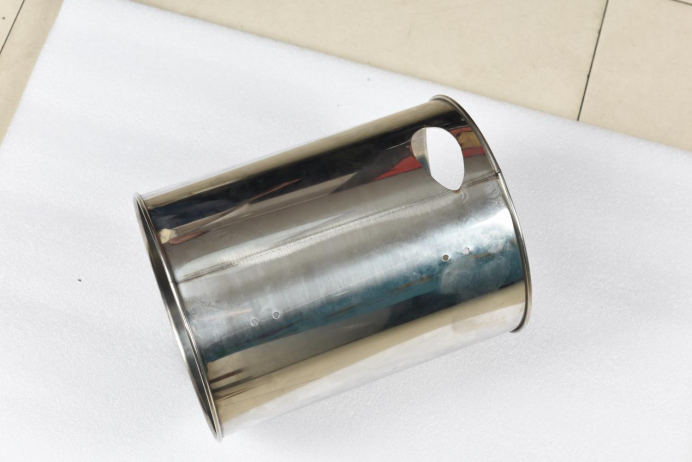

1. **Water pipe joint welding**: The laser welding machine can accurately weld water pipe joints to ensure that there is no leakage at the joint and improve the sealing performance of the product. At the same time, due to the small welding deformation, the joint appearance is smooth and beautiful, which meets the aesthetic requirements of bathroom products.

2. **Welding of valves, tees and other accessories**: In addition to water pipe joints, laser welding machines can also be used for welding of valves, tees and other bathroom accessories. The welding requirements for these accessories are equally strict. With its high-precision and high-quality welding characteristics, laser welding machines can meet the welding needs of these complex accessories.

3. **Stainless steel faucet welding**: Stainless steel faucets occupy an important position in bathroom products. Traditional welding methods are difficult to ensure the welding quality at the faucet corners, and are prone to sparse welds and leaks. The laser welding machine can easily deal with this problem and achieve welding without dead corners at the faucet corners, ensuring stable and reliable welding quality.

3. Application prospects of laser welding machines in the sanitary ware industry

As the sanitary ware industry's requirements for product quality and process level continue to improve, the application prospects of laser welding machines in the sanitary ware industry will be broader. In the future, laser welding machines will continue to give full play to their high-precision, high-efficiency, and high-quality welding advantages to promote the development of the sanitary ware industry to a higher level. At the same time, with the continuous advancement of technology and the gradual reduction of costs, laser welding machines will become more popular and civilian, bringing benefits and convenience to more sanitary ware companies.

In short, the application of laser welding machines in the welding of water pipe joints in the sanitary ware industry is an important symbol of technological innovation and industrial upgrading. It not only improves the quality and performance of bathroom products, but also promotes the rapid development and progress of the entire industry.

Related product links

Welder News

Welder News