- No.609, Centre Of Huijin Nanxiang, Yinxiang Road, Nanxiang Town, Jiading District, Shanghai, China

- sherry@sanmachines.com

- +86-18616767021

Laser Cleaning Technology Fights Contaminants!

What is laser cleaning?

Simply put, it is the process of using high-power laser beams to clean metal and non-metallic surfaces. Fiber laser cleaning machines skillfully remove rust, dust, paint, and even centuries-old coatings from a variety of surfaces.

In this process, pulsed fiber lasers can handle the heavy lifting instead of harsh chemicals or labor-intensive cleaning. Their function is to emit powerful light energy that interacts with pollutants to evaporate or degrade them into harmless chemicals, resulting in a chemical-free process.

The accuracy and non-contact nature of laser cleaning make it ideal for protecting delicate historical artifacts, restoring metal surfaces and revitalizing industrial equipment.

In conclusion, laser cleaning is about more than just cleaning; it's about preserving the past, ensuring safety, and embracing a sustainable future.

Why does laser cleaning technology fight contaminants?

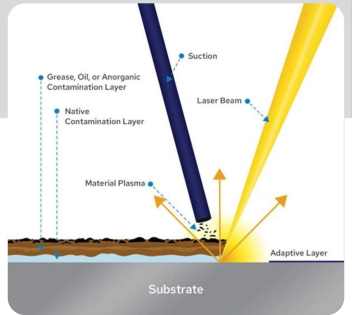

You may be wondering why laser cleaning removes unwanted material effectively. It all comes down to the massive power of concentrated laser light.

Consider using a magnifying glass to focus sunlight on a point and watch it become very hot. Laser cleaning works similarly but with much greater precision.

The laser beam is similar to a superhero's laser vision, except it's for cleaning. When it comes into contact with contaminants, it absorbs them and heats up rapidly.

This rapid heating causes surface materials (such as dust or rust layers) to degrade and disappear, leaving the surface clean and bright.

What's even more interesting about the laser cleaning system is that, like a laser surgeon, it can target only contaminants without affecting the underlying substrate.

So whether you're removing graffiti from a historic building or removing rust from a classic car, laser cleaning solutions can come in and save the day.

Don't worry, there are more exciting ones! Unlike traditional methods, laser cleaning is also environmentally friendly. It is environmentally friendly as no toxic chemicals are involved.

So, laser cleaning is the high-tech superhero of the scene when it comes to fighting toxins, and you can choose the best fiber laser machine to make the planet cleaner and greener.

The process of using laser cleaner technology to fight contaminants

Although laser cleaning may seem like a magical process, it is a precise and systematic process. Let's take a look at the stages involved in using this effective technology to address contaminants:

Step 1. Surface AssessmentThe trip begins with a thorough inspection of the contaminated surface. This stage determines the type and extent of contamination, allowing the professional to select the type of laser, appropriate laser settings, pretreatment, and applicable power of the laser cleaning machine.

Step 2. Laser calibration

The next step is to calibrate the laser. This involves varying laser intensity, laser pulse energy, pulse duration, and focus to provide optimal cleaning results.

Step 3. Laser Beam Delivery

Laser cleaning systems use different methods to deliver a laser beam to a surface. Handheld system devices or robotic arms equipped with laser heads can be used in these ways to ensure precise targeting.

Step 4. Contaminant Removal

After the pulsed laser is emitted, it interacts with contaminants on the surface. This exposure may require ablation thresholds, oxidation, or other chemicals, depending on the cleaning procedure used. Contaminants are dissolved or evaporated, resulting in a clean surface.

Step 5. Contaminant capture

Specialized systems capture and filter removed contaminants to avoid re-contamination and ensure the safety of the surrounding environment and other materials. This is especially important when handling hazardous materials.

Step 6. Surface protection

Since laser cleaners are non-contact, underlying materials are not affected. This is especially important for sensitive surfaces.

Significant advantages of laser cleaning machines

Consider a cleaning procedure that not only restores surfaces to pristine condition, but is also eco-friendly, cost-effective, and highly accurate. It has many advantages and is changing the way we deal with pollution problems:

1. Accuracy

Laser cleaning solutions are like skilled surface surgeons. It can precisely target certain contaminants while leaving the rest unaffected. Due to its accuracy, it is ideal for fragile items, metal cleaning, the automotive industry, and irreplaceable artifacts.

According to the BBC lasers can remove age-old grime from artwork and have been used to great effect on stone and metal artifacts. Now it has been successfully used on the frescoes of the old chapel and the Manto chapel of the church of Santa Maria della Scala in Siena, Italy.

2. Environmental friendly

Unlike traditional cleaning procedures that can include harsh chemicals and waste, laser systems are safe and environmentally friendly. It produces very little waste and contains no toxic chemicals, making it an environmentally friendly alternative.

3. No surface damage

Say goodbye to wear and damage caused by abrasive products or rigorous cleaning. This laser cleaner gently and effectively removes impurities without harming the underlying material and preventing it from deteriorating.

4. Versatility Rules

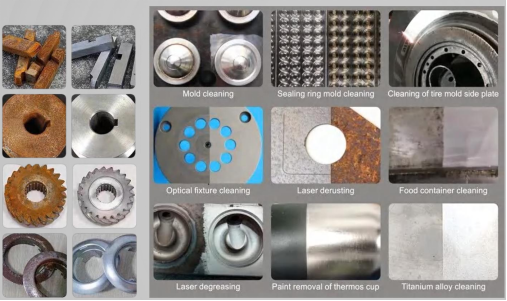

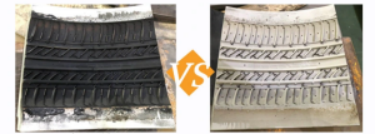

This fiber laser technology can handle a variety of surface cleaning jobs, from rust and paint removal to graffiti cleaning and delicate restoration jobs. Its scalability makes it a popular choice in various fields.

5. Safety supplies

Traditional cleaning procedures can put you at risk such as chemical exposure or inhaled dust. Since laser cleaners eliminate the need for such harmful products and technologies, they are a safer option.

6. economy

While laser technology may seem high-tech, it can actually save you money in the long run. Its accuracy reduces the need for rework or material replacement, saving labor costs in the long run.

Laser cleaning equipment is durable and requires little to no maintenance. This means fewer difficulties associated with maintaining the system and greater cost advantages.

7. Ability to save time

Because laser cleaning is fast, you receive results faster. Your projects will be more efficient as there is less downtime for cleaning and maintaining your production line.

All in all, the benefits of laser cleaning are a game changer in the world of surface cleaning. Its accuracy, eco-friendliness and adaptability make it a superhero in the fight against contaminants, ensuring surfaces are not only clean but well-preserved.

Related product links

Welder News

Welder News