- No.609, Centre Of Huijin Nanxiang, Yinxiang Road, Nanxiang Town, Jiading District, Shanghai, China

- sherry@sanmachines.com

- +86-18616767021

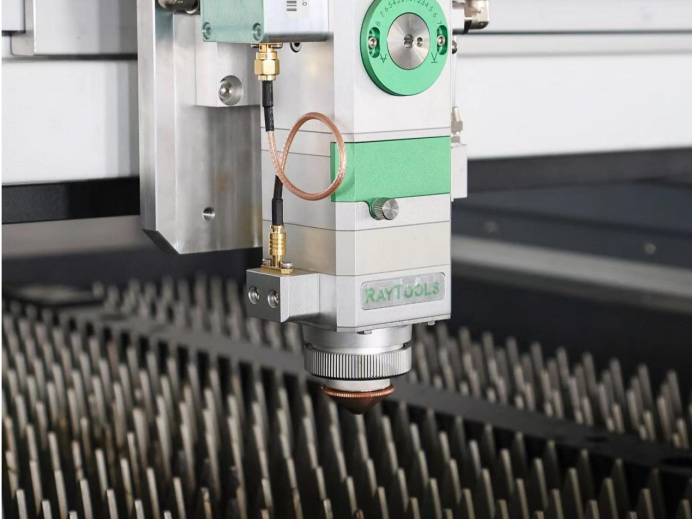

Laser cutting machine achieves bright surface cutting method!

Today, SAN Laser, a laser cutting machine manufacturer, will talk to you about the six methods of laser cutting machine to achieve bright surface cutting.

In the processing technology of laser cutting machine, the cross section of carbon steel can be cut very smoothly, achieving the effect of "mirror", commonly known as "bright surface cutting". Bright surface cutting is mainly used for medium and thick carbon steel. Bright surface cutting cannot be achieved if the steel plate is too thin or too thick.

1. Control the cutting speed. Too fast cutting speed will lead to incomplete burning of the material and the workpiece cannot be cut through. Too slow speed will lead to excessive burning and the workpiece will melt and deform. Under the premise of ensuring the quality of the workpiece, the cutting speed should be increased as much as possible.

2. Adjust the nozzle height. The nozzle height will affect the beam quality, oxygen purity and airflow direction. The lower the nozzle, the better the beam quality, the higher the oxygen purity, and the smaller the airflow direction, so the bright surface cutting should be as low as possible.

3. Adjust the cutting pressure. In carbon steel oxygen cutting, the combustion of the material releases a lot of heat, so the oxygen pressure cannot be too large. Generally speaking, the lower the pressure in the cutting range, the brighter the cutting section, but in order to ensure the stability of the cutting, it is usually a certain proportion based on the cutting pressure.

4. Adjust the cutting power. For plates of different thicknesses, the greater the thickness, the higher the power required.

5. Adjust the cutting focus. The beam emitted from the nozzle of the fiber laser is of a certain diameter. When cutting on the bright surface, a smaller nozzle is usually used. If the focus is too large, it will cause the nozzle to heat up, affect the cutting quality and stability, and even directly cause the nozzle to be damaged. Therefore, it is necessary to find out the maximum focus value that the nozzle size can withstand, and then adjust it.

6. Select the nozzle size. The smaller the half nozzle, the brighter the cutting section, and the better the effect.

If you want to know more, please continue to follow us. SAN LASER, a laser cutting machine manufacturer, is a laser equipment manufacturer integrating R&D, production and sales. It mainly sells laser cutting machines, laser tube cutting machines, laser welding machines, laser marking machines and other series of equipment. The company’s R&D team has 20 years of industry experience and focuses on developing products with stable performance and excellent quality. It is committed to providing systematic laser intelligent manufacturing solutions for global customers. All are welcome to consult and purchase.

Cutter News

Cutter News