- No.609, Centre Of Huijin Nanxiang, Yinxiang Road, Nanxiang Town, Jiading District, Shanghai, China

- sherry@sanmachines.com

- +86-18616767021

Laser marking equipment is becoming more and more diverse, and its application range is becoming wider and wider!

1. UV laser marking machine

The UV laser is developed using a 355nm UV laser. It uses the third-order intracavity frequency doubling technology and uses laser energy to break the bonds between atoms or molecules, turning them into small molecules and evaporating them. Compared with infrared lasers, UV lasers are truly cold lasers with very little thermal effect. It can greatly reduce the mechanical deformation of materials and has a small processing thermal effect. Therefore, it is mainly used for ultra-fine marking and engraving, especially for high-speed segmentation of glass materials for food and pharmaceutical packaging materials and complex pattern cutting of silicon wafers. UV marking machine is the preferred product for customers with high requirements for marking. It has the characteristics of high photoelectric conversion rate, stable operation of the whole machine, high marking accuracy, high work efficiency, modular planning, and convenient equipment protection. It is mainly used for the identification of the surface of packaging bottles of polymer materials such as iPhones, cosmetics, medicines, and foods; marking and scribing of flexible PCB boards; micropores and blind holes of silicon wafers; liquid crystal glass, glassware surface, metal surface coating, plastic keys, electronic components, gifts, communication equipment, building materials, etc.

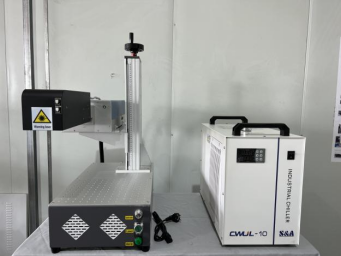

2. Fiber laser marking machine

Fiber laser marking machine is currently widely used. It uses fiber laser to output laser, and then uses high-speed scanning galvanometer system to realize marking function. Fiber laser marking machine has high photoelectric conversion efficiency, air cooling, small size, good output beam quality, high reliability, long life, energy saving and environmental protection, and can engrave metal materials and some non-metallic materials. The effect of marking is to expose the deep material through the evaporation of surface material, or "carve" traces through the chemical and physical changes of surface material caused by light energy, or burn part of the material through light energy, and display the required etching pattern, text, barcode and other graphics. It is mainly used in deep, smooth and high-fineness fields. It is widely used in integrated circuit chips, computer accessories, industrial bearings, clocks and watches, electronic communication products, aerospace devices, various automotive parts, household appliances, hardware tools, molds, wires and cables, food packaging, jewelry and other fields of graphic and text identification, tobacco, military industry, large-scale production line operations, marking speed is 3~12 times that of traditional first-generation lamp pump marking machine and second-generation semiconductor marking machine.

3. CO2 laser marking machine

CO2 laser marking machine, commonly known as CO2 marking machine, its key core component is laser, which is divided into glass radio frequency tube and metal radio frequency tube. From the perspective of market application, metal radio frequency tube has high cost performance, service life can reach more than 100,000 hours, and laser wavelength is 10.64μm. It belongs to the mid-infrared band, has high power, high electro-optical conversion rate, and uses CO2 gas as working material. CO2 laser marking machine is a high-performance laser marking equipment, which uses laser beam expansion, galvanometer, focusing, and finally controls the deflection of galvanometer to achieve marking. The marking speed is fast and suitable for marking most non-metallic materials. The effect of marking is to expose the deep material through the evaporation of the surface material, so as to engrave beautiful patterns, trademarks, dates, logos or text. At present, CO2 laser marking machine is mainly used in some occasions with high precision requirements. It is used in food, medicine, alcohol, electronic components, integrated circuits, electrical appliances, mobile communications, building materials, PVC pipes and other industries.

Company News

Company News