- No.609, Centre Of Huijin Nanxiang, Yinxiang Road, Nanxiang Town, Jiading District, Shanghai, China

- sherry@sanmachines.com

- +86-18616767021

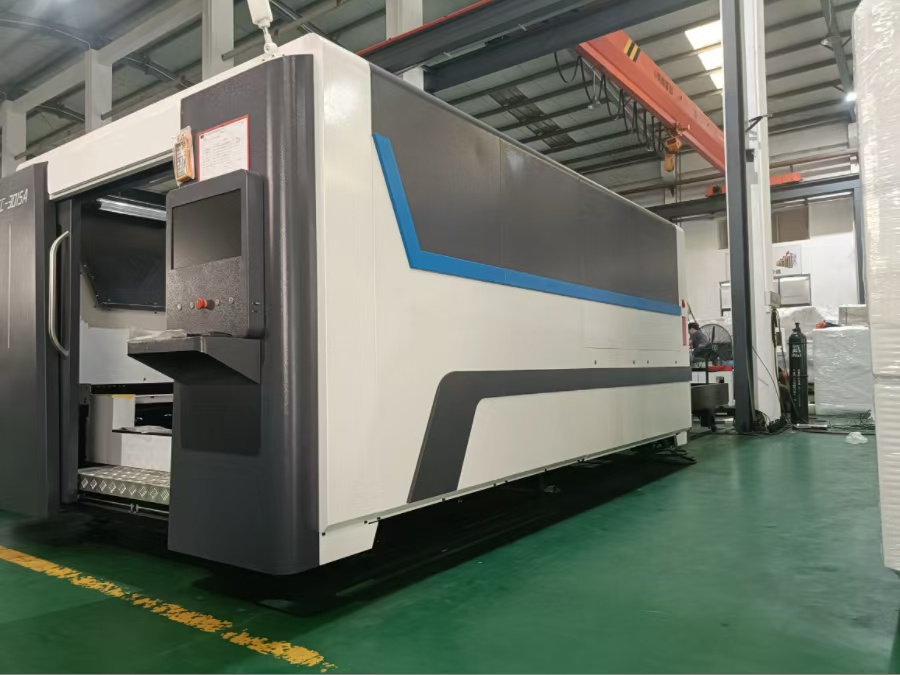

Metal laser cutting machine: a precise tool for modern manufacturing industry!

As the core equipment of modern manufacturing industry, metal laser cutting machine is reshaping the face of metal processing industry. This high-tech equipment integrating optical, mechanical, electronic and computer technologies plays an increasingly important role in industrial production with its excellent cutting accuracy and efficiency.

Working principle of metal laser cutting machine

The working principle of metal laser cutting machine is based on the thermal effect of high-energy laser beam. The high-density beam generated by the laser generator is focused through the optical system to form a very small spot on the metal surface, and instantly generates high temperature to melt or vaporize the material. The auxiliary gas system works at the same time to blow the molten material away from the cutting area to form an incision.

The core components of the equipment include laser generator, optical system, CNC system and cooling system. The laser generator provides a stable high-energy beam, the optical system ensures the transmission and focusing of the beam, the CNC system controls the cutting path, and the cooling system maintains the stable operation of the equipment. The collaborative work of these components ensures the high precision and high efficiency of the cutting process.

Compared with traditional cutting methods, laser cutting has obvious advantages. It can achieve cutting of complex shapes, smooth incision without burrs, small material deformation, and no subsequent processing. These characteristics make laser cutting a process in the field of precision manufacturing.

Technical development of metal laser cutting machine

The breakthrough of fiber laser technology is an important progress in recent years. Compared with traditional CO2 laser, fiber laser has higher energy conversion efficiency, smaller equipment volume and lower operating cost. This has significantly improved the performance of metal laser cutting machine and further expanded its application range.

Intelligent upgrading is another important trend. Modern metal laser cutting machines are generally equipped with functions such as automatic focusing, automatic edge finding, and remote diagnosis. Through the combination with industrial Internet technology, real-time

monitoring and predictive maintenance of equipment status are realized, which greatly improves production efficiency and equipment reliability.

In terms of application fields, metal laser cutting machines have expanded from traditional metal processing industries to high-end manufacturing fields such as new energy vehicles, aerospace, and precision electronics. Especially in the processing of key components such as battery trays and motor cores of new energy vehicles, laser cutting technology has shown unique advantages.

Market prospects of metal laser cutting machines

The global market scale continues to expand

The direction of technological innovation is mainly focused on increasing cutting speed, expanding the range of processing materials, and reducing energy consumption. New processes such as ultrafast laser cutting technology and composite processing technology are under development, which are expected to further expand the application boundaries of laser cutting.

As a representative of advanced manufacturing technology, metal laser cutting machines are promoting the transformation of manufacturing industry towards intelligence and precision. With the continuous advancement of technology and the expansion of application fields, it will surely play a more important role in future industrial production and provide strong support for the high-quality development of manufacturing industry.

Related product links

Cutter News

Cutter News