- No.609, Centre Of Huijin Nanxiang, Yinxiang Road, Nanxiang Town, Jiading District, Shanghai, China

- sherry@sanmachines.com

- +86-18616767021

Method for preventing laser welding from producing air hole!

The principle of metallurgy is utilized to minimize the formation of pores by introducing an active gas that dissolves in the weld or reacts with the molten metal to form compounds. Pulse laser welding is also employed to alter the behavior of small holes and reduce the influx of shielding gas.

While these methods can help reduce the number of pores, they cannot completely eliminate them. The beam swing method is used to minimize or eliminate pores in deep penetration laser welding.

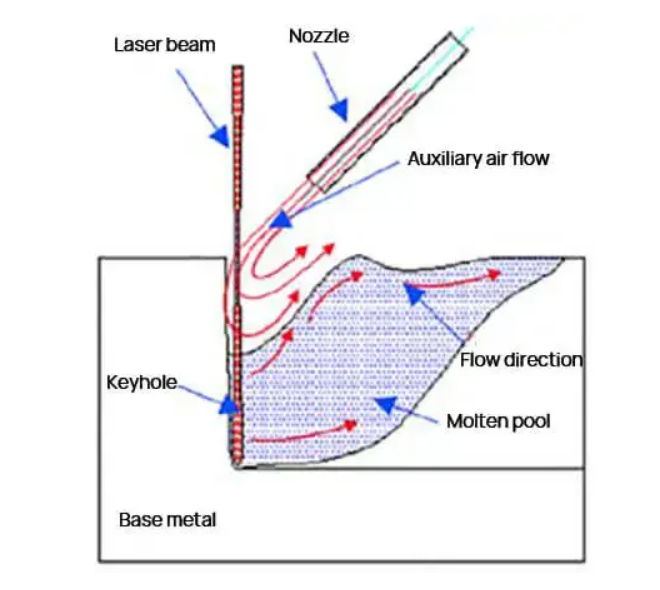

The reciprocating movement of the beam over the weld prolongs the residence time of liquid metal in the welding pool and increases the heat input per unit area, reducing the depth-to-width ratio of the weld. This promotes bubble formation and helps eliminate pores. Additionally, the oscillation of the beam flow stirs the welding pool, increasing convection and helping to eliminate pores.

By using a surface cleanliness meter, the cleanliness of parts can be quickly and accurately assessed. This data helps to avoid the impact of human subjectivity in the cleaning process and optimize it for greater efficiency, reducing rework and production costs.

Related product links

Welder News

Welder News