- No.609, Centre Of Huijin Nanxiang, Yinxiang Road, Nanxiang Town, Jiading District, Shanghai, China

- sherry@sanmachines.com

- +86-18616767021

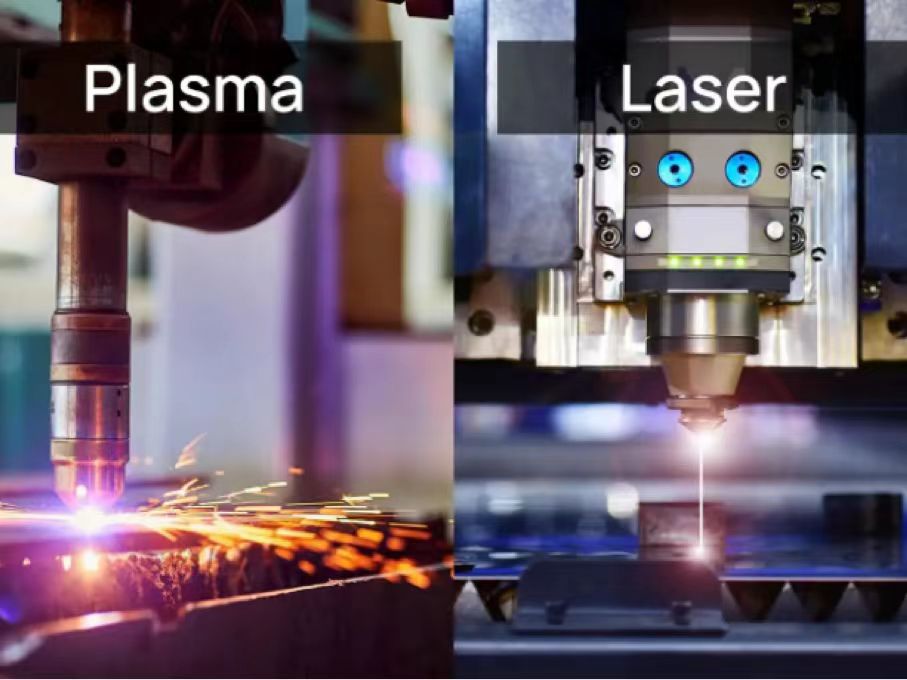

Plasma Cutting vs Laser Cutting: The Differences Explained!

In the rapidly evolving world of metal cutting, a battle rages between laser and plasma. As technology advances, the landscape shifts.With the rise of multi-kilowatt lasers, and now with the widespread adoption of 60kW lasers, laser cutting is expanding into the realm of medium and thick plate cutting. During this time, the plasma cutting market has seen a dramatic decline and is gradually being replaced in certain application scenarios.

1. Comparison between fiber laser cutting and plasma cutting

Fiber laser cutting | Plasma cutting | |

Principle | A high-power density laser beam is employed to scan the surface of the material, rapidly heating it to temperatures ranging from thousands to tens of thousands of degrees Celsius.

| With oxygen or nitrogen as the working gas, a high-temperature and high-speed plasma arc serves as the heat source, locally melting the metal being cut. |

Material | Metal materials, special metal materials and non-metallic materials | Carbon steel, stainless steel, aluminum, copper, cast iron and other metal materials |

Cutting thickness | Medium thick plate | Medium thin plate |

Cutting accuracy | Finish machining (within 0.2mm) | Rough machining (within 1mm) |

Slit width | Very small (0.2 ~ 0.3mm) | Small |

Heat affected zone | Very small (width 0.1mm) | Small |

Plate deformation | Very small | Small |

2. Advantages of fiber laser cutting over plasma cutting

Fiber laser cutting | Plasma cutting | Fiber laser advantages | |

Positioning accuracy | 0.14mm | 0.4mm | High accuracy |

Section perpendicularity | 0.2mm(40mm) | 5mm(40mm) | No finishing required |

Slit width | 0.2-1.5mm | 2-5mm | Save materials |

Reserved edge and common edge | 3-4mm | 10mm | Save materials |

Heat affected zone | 0.1-0.4mm | 0.5-2.0mm | Small deformation |

Section quality | Excellent, less slag hanging | Normal | No grinding required |

Cutting speed (within 20mm) | Very fast | Normal | High production efficiency |

Cut a small hole | Diameter depth ratio: 10-20% | Unable to cut hole | Save drilling machine and transfer |

Beveling | Beveling | Generally not | Saving beveling machine |

Work environment | Clean | Smoke filled the house | Health and environmental protection |

Related product links

Cutter News

Cutter News